In today’s industrially developed era, gate valves have become an indispensable part of pipeline control in controlling the flow of liquid or gas in pipelines. They offer a reliable, full-flow shutoff solution, making them a top choice across industries. In this guide, we’ll dive deep into what gate valves are, their types, applications, and the advantages they bring to your operations.

Table of Contents

ToggleWhat is The Gate Valve?

A gate valve is one of many valves that controls the flow of liquid/gas in a pipeline by lifting or lowering the gate (or wedge) in the valve body. It provides either a fully open or fully closed position, ensuring a clear, unobstructed flow path when open, which minimizes pressure loss. This makes them ideal for water, oil, gas, and steam applications.

Types of Gate Valves

There are many types of gate valves, each designed for a specific application.

By Material:

Stainless Steel Gate Valves: Stainless steel is one of the most popular materials for gate valves. High corrosion and rust resistance, suitable for high pressure and high temperature environment, long service life and low maintenance cost. Commonly found in chemical processing plants, water treatment facilities, and oil and gas pipelines.

Ceramic Gate Valves: Designed for highly abrasive environments where traditional metal valves would wear down quickly. Ceramic materials offer extreme hardness and resistance to abrasion, making these valves ideal for industries handling abrasive slurries, sand, or other harsh materials. Ceramic gate valves are commonly used in mining, power generation, and other heavy industrial sectors.

Cast Iron Gate Valves: Widely used for gate valves in non-corrosive applications such as water, air, and non-hazardous fluids. Cast iron gate valves are generally more affordable and are suitable for low-pressure applications. However, they are not recommended for environments with corrosive fluids or where high durability is required.

By Features:

Wedge Gate Valves: Featuring a solid or flexible wedge that fits snugly between two seats, ensuring tight sealing. These are widely used for high-pressure applications.

Parallel Gate Valves: These use a flat gate between two parallel seats and are often used in low-pressure systems.

Rising Stem Gate Valve: The valve stem moves up and down when the valve is operated, providing a visual indication of whether the valve is open or closed.

Non-Rising Stem Gate Valves: The stem remains in place as the gate moves up and down. This design is preferred in tight spaces where height clearance is a concern.

At TOT Valve, we specialize in stainless steel and ceramic gate valves, which offer enhanced durability, corrosion resistance, and suitability for high-temperature environments.

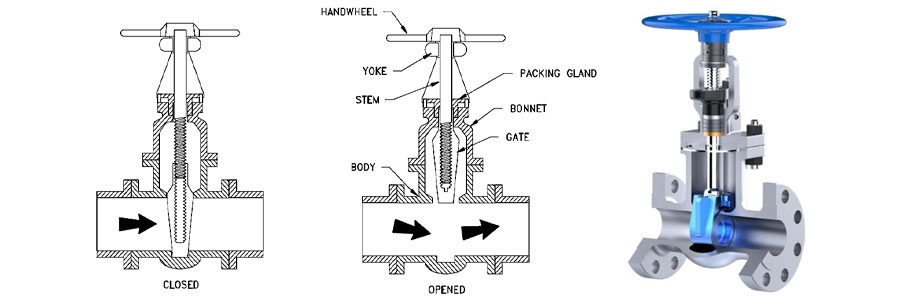

What Components Does a Gate Valve Have?

Gate valves generally consist of the following key components, which together control the flow of liquid or gas in a pipeline:

Valve Body: The main body of the valve, TOT Valve is usually made of premium 304/316 stainless steel or ductile iron.

Gate: The flat or wedge-shaped disk that opens or closes the valve.

Stem: The shaft connected to the gate, which moves it up or down.

Seats: The surfaces against which the gate seals when closed.

Bonnet: The top cover of the valve body, providing access to the stem and other internals.

Packing: A seal around the valve stem to prevent leakage.

How Does a Gate Valve Work?

Gate valves operate by moving the gate up or down within the valve body. When the valve gate is fully opened, the gate is completely out of the flow channel, allowing the fluid to flow unimpeded. When the valve gate is fully closed, the gate is tightly pressed against the valve seat, completely blocking the flow of fluid. This simple design provides reliable shutoff capability with minimal pressure drop when open.

Gate Valve Advantages and Disadvantages

Advantages:

- Full, unobstructed flow when open, reducing pressure drop.

- Suitable for both liquid and gas applications.

- Because the valve is made of high-quality stainless steel or ceramics as raw materials, it can maintain its long service life even in harsh environments.

Disadvantages:

- Not ideal for throttling purposes, as partial opening can cause damage to the gate.

- Requires more space for operation compared to other valve types, particularly rising stem designs.

What are Gate Valves Used for?

Because of the high-quality materials and excellent performance of stainless steel or ceramic gate valves, their applications are also very extensive. Next, we will briefly introduce the industries in which gate valves are commonly used:

Water treatment: Controlling the flow of water in pipelines.

Oil and Gas: Managing the flow of crude oil and natural gas in refineries.

Power Generation: Handling steam flow in power plants.

Chemical Processing: Regulating corrosive or abrasive fluids.

Their versatility and robust performance make them a popular choice in these demanding industries.

The Importance of Proper Valve Selection

Choosing the right gate valve is crucial for the efficiency and safety of your system. Factors such as material compatibility, pressure ratings, and the type of fluid being transported must be considered. TOT Valve offers both stainless steel for corrosion-resistant applications and ceramic gate valves for high-abrasion environments. Selecting the correct valve will reduce downtime, enhance operational safety, and improve the lifespan of your system.

Installation and Maintenance of Gate Valves

If you want to ensure the life of the gate valve or even extend its service life, you must ensure that the necessary installation specifications should be followed during its installation.

Before installing the gate valve, the sludge, waste residue, etc. in the pipeline must be flushed away.

The valve can be installed in a flat or upright form, which is convenient for handwheel operation.

Ensure that during installation, the pipeline flanges are spaced apart so that there is enough space to insert or remove the valve during maintenance.

Ensure that the bolt pressure connecting the valve to the pipeline is evenly distributed.

After the gate valve is installed, it should be tested to ensure that the valve operates stably in its position.

It is important to regularly inspect the gate, seats and packing for wear, especially in high pressure or high temperature environments.

Tips: If the gate valve parts need to be replaced, please be sure to release the pressure in the pipe or valve first, and then disassemble the gate valve in the reverse order of the installation process.

TOT Valve Gate valves are designed for ease of maintenance, helping you minimize operational disruptions.

What To Consider Before Buying a Gate Valve?

When selecting a gate valve, you should consider:

- Material: For corrosive environments, stainless steel or ceramic valves are best.

- Pressure and Temperature Ratings: Ensure the valve can handle your system’s operating conditions.

- Size: Match the valve size to your pipe diameter and flow requirements.

- End Connections: Choose between flanged, threaded, or welded ends depending on your installation setup.

Gate Valve Manufacturers

It’s essential to choose a reliable gate valve manufacturer to ensure product quality and after-sales support. TOT Valve As a leading gate valve manufacturer and exporter, we have earned a reputation for delivering durable, high-performance gate valves. Our stainless steel and ceramic options are rigorously tested to meet international standards, making us a trusted partner for distributors and engineering companies worldwide. Contact us now and let TOT Valve help you explore new markets.

Conclusion

Gate valves are an indispensable part of many industrial applications, offering reliable flow control and durability. Choosing the right valve type, size, and material is key to maintaining efficient operations. As a top manufacturer, TOT Valve provides high-quality, customizable solutions that meet your specific needs. Our expertise in stainless steel and ceramic gate valves ensures you get the best performance for your applications.

FAQ

Do Gate Valves Come in Different Sizes?

Yes, gate valves come in various sizes to suit different pipe diameters and flow requirements. Standard sizes typically range from ½ inch to 48 inches or more, depending on the application. At TOT Valve, we manufacture gate valves in various sizes, ensuring compatibility with diverse industrial systems, from small-scale setups to large pipelines.

How Do Gate Valves Work?

They control the flow by lifting or lowering a gate inside the valve, providing full-flow shutoff.

How Often Should Gate Valves be Maintained?

Regular maintenance, including inspections and part replacements, should be done based on the valve’s operational environment, usually annually or bi-annually.