JIS Gate Valve

This JIS gate valve from TOT is a type of stainless steel gate valve, which is simple in design and complies with Japanese standards. The JIS gate valve consists of a valve body, a valve cover, a valve stem, a valve seat ring, a handwheel and a gate. The valve stem that connects the handwheel and the valve disc is responsible for driving the valve disc to the correct position.

We can provide you with manual, bevel gear transmission and electric stainless steel gate valves. Contact us now to get the most favorable ex-factory price.

Description

When the valve is open, the gate moves in the bonnet to allow full flow. When the gate valve is closed, the gate moves down into the seat, achieving a positive seal.

You can usually use this valve to stop or start flow, because they are not designed for throttling, the valve only operates in the fully open position or the fully closed position. We can also provide you with a two-way gate valve, allowing it to be used in both directions.

Flanged stainless steel gate valves are suitable for ANSIClass150~900, PN2.0~16.0MPa, JIS10~20K, working temperature -29~425℃ (carbon steel) and -40~500°C (stainless steel) on various pipelines, used to cut off or connect the media in the pipeline.

You can use our stainless steel gate valves for a variety of media fluids such as water, steam, oil, nitric acid, acetic acid, strong oxidizing media and urea.

JIS Gate Valve Execution Standard

| Design & Manufacture | Structure Length | Connection Flange | Pressure-temperature Rating | Test & Inspection |

| JIS B2073 B2083 | JIS B2002 | JIS B2212 B2214 | JIS B2073 B2083 | JIS B2003 |

Structural Characteristics

– Excellent flow and minimized friction loss

– Product design and manufacturing meet the requirements of JIS advanced standards, reliable sealing and excellent performance

– Compact and reasonable structural design, beautiful appearance

– Adopt wedge-type elastic gate structure, medium and large diameters are equipped with rolling bearings, easy to open and close

– A full range of valve body materials, packing and gaskets are reasonably selected according to actual working conditions or user requirements, Applicable to various pressure, temperature and medium working conditions

– Select a variety of JIS piping flange standards and flange sealing surface types to meet various engineering needs and user requirements

– Excellent performance in humid or corrosive environments

Main Components Material

The TOT Valve body and wedge are cast or forged from a variety of high-quality materials, including stainless steel, cast steel and alloy steel, depending on the requirements of your gate valve application scenario.

The main materials of Packing and Gasket are PTFE or Graphite.

If you are interested in our gate valve materials, you can contact us by leaving your information in the form on the right.

| Name | Material | ||||||||

| Valve Body/Bonnet | CF8 | CF3 | CF8M | CF3M | WCB | LCB | WC6 | WC9 | C5 |

| Wedge | CF8 | CF3 | CF8M | CF3M | WCB | LCB | WC6 | WC9 | C5 |

| Stem | F304 | F304L | F316 | F316L | 2CR13 | F304 | F304 | F304 | F304 |

| Stem Nut | Aluminium Bronze | ||||||||

| Packing | PTFE | Graphite | |||||||

| Gasket | PTFE | Graphite | |||||||

| Gland | CF8 | CF3 | CF8M | CF3M | WCB | LCB | WC6 | WC9 | C5 |

| Bolt | Stainless Steel | 35CrMoA | |||||||

| Nut | Stainless Steel | 45, 35CrMoA | |||||||

| Handwheel | Cast Steel | ||||||||

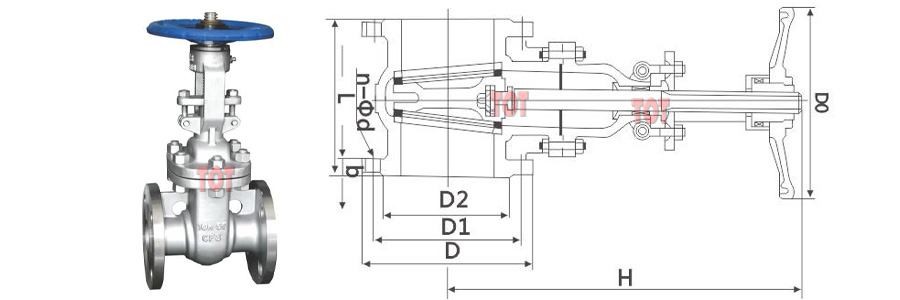

Main External and Connection Dimension

TOT Valve can provide you with JIS Gate Valve of various sizes and models. We list all existing JIS Gate Valve Sizes.

The data we provide can be used for your reference. If you do not have the gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| DN | 10K | |||

| mm | in | L | H | DO |

| 50 | 2 | 178 | 409 | 200 |

| 65 | 2½ | 190 | 535 | 250 |

| 80 | 3 | 203 | 570 | 250 |

| 100 | 4 | 229 | 590 | 250 |

| 150 | 6 | 267 | 630 | 300 |

| 200 | 8 | 292 | 960 | 350 |

| 250 | 10 | 330 | 1158 | 400 |

| 300 | 12 | 356 | 1378 | 450 |

| 350 | 14 | 381 | 1543 | 500 |

| 400 | 16 | 406 | 1738 | 600 |

| 450 | 18 | 432 | 1959 | 600 |

| 500 | 20 | 457 | 2214 | 680 |

| 20K | ||||

| 50 | 2 | 216 | 480 | 200 |

| 65 | 2½ | 241 | 510 | 250 |

| 80 | 3 | 283 | 580 | 280 |

| 100 | 4 | 305 | 700 | 350 |

| 150 | 6 | 403 | 940 | 400 |

| 200 | 8 | 419 | 1190 | 450 |

| 250 | 10 | 457 | 1390 | 500 |

| 300 | 12 | 502 | 1600 | 500 |

| 350 | 14 | 762 | 1750 | 600 |

| 400 | 16 | 838 | 1900 | 600 |

| 450 | 18 | 914 | 2320 | 650 |

* We are not just providing simple quotes but experts in selection, calculation, and drawing.