API Swing Check Valve

API Check Valve, also known as non-return valve, one-way valve, reverse flow valve, is an automatic valve, its main function is to prevent the medium from flowing back, prevent the pump and drive motor from reversing, and the release of the container medium.

API check valves produced by TOT Valve are designed and manufactured in full accordance with American standards, with beautiful and advanced structures.

Contact us now to install an automatic opening and closing API check valve for your application.

Description

The API swing check valve provided by TOT is a stainless steel check valve. This stainless steel swing sheck valves also known as tilt disc valves a high-quality stainless steel casting body.

The API swing check valves we produce are valves that automatically open and close the valve discs based on the flow of the medium itself, which you can use to prevent medium backflow.

The valve disc hanging on the top of the valve allows water to flow in only one direction with minimal force (1/2 pound of opening pressure), and it can prevent attempts to flow in the opposite direction in your application.

Structural Characteristics

– Excellent flow and minimized friction loss

– Compact and reasonable structural design, beautiful appearance

– Excellent performance in humid or corrosive environments

– Product design and manufacturing meet the requirements of API advanced standards, reliable sealing and excellent performance

– A full range of valve body materials, packing and gaskets are reasonably selected according to actual working conditions or user requirements, Applicable to various pressure, temperature and medium working conditions

Next, we will introduce the relevant data on the design and manufacturing execution specifications of API swing check valve, materials used for main components, and specifications, etc., which we hope will help you choose the appropriate swing check valve for your project application.

API Swing Check Valve Specification

| Design | Structure Length | Connection flange | Test and Inspection | Pressure & Temperature |

|---|---|---|---|---|

| BS 1868/API 6D ASMEB16.34 |

ASME B16.10 | ASME B16.5 SMEB16.47A |

API 598/API 6D | ASME B16.34 |

Swing Check Valve Performance Parameter

In order for the swing check valve to work properly and perform optimally, you should first understand its pressure limit range when making a choice. Below are the pressure test results of our API swing check valve for your reference.

| Name | 150(Lb) | 300(Lb) | 600(Lb) | 900(Lb) | 1500(Lb) | 2500(Lb) |

| PN(MPa) | 2.0 | 5.0 | 10.0 | 15.0 | 25.0 | 42.0 |

| Shell Strength Test Pressure( MPa) | 1.5 Times the nominal pressure at room temperature | |||||

| High-pressure Sealing Test Pressure(MPa) | 1.1 Times the nominal pressure at room temperature | |||||

| Nominal Pressure at Room Temperature(MPa) | According to ASME B16.34 pressure temperature rating | |||||

Swing Check Valve Main Components Material

The TOT Valve body are cast or forged from a variety of high-quality materials, including stainless steel, cast steel and alloy steel, depending on the requirements of your swing check valve application scenario. The main materials of Gasket are Graphite.

If you are interested in our swing check valve materials, you can contact us by leaving your information in the form on the right.

| Part | Material | |||||

| Body | A216 WCB | A217 WC6 | A351 CF8 | A351 CF8M | A351 CF3 | A351CF3M |

| Valve Cover | A216 WCB | A217 WC6 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| valve plate | A216 WCB | A217 WC6 | A351 Cf8 | A351 CF8M | A351 CF3 | A351 CF3M |

| sealingface | 13Cr/STL | STL | ||||

| Stem | A182 F6a | A182 F11 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| Gasket | 304+Flexible Graphite/Soft Iron | 304+Flexible Graphite/F304 | 304+Flexible Graphite/F304 | 316+Flexible Graphite/F316 | 304L+Flexible Graphite/F304L | 316L+Flexible Graphite/F316L |

| Bolt | A193 B7 | A193 B16 | A193 B8 | A193 B8M | A193 B8 | A193 B8M |

| Nut | A194 2H | A1944 | A1948 | A1948M | A1948 | A1948M |

| Temperature | -29~425℃ | -29~540℃ | -46~425℃ | -46~425℃ | -46~425℃ | -46~425℃ |

| Suitable Medium | Water,Steam,Oil,etc. | Steam | Nitric Acid Weak Corrosion Media | |||

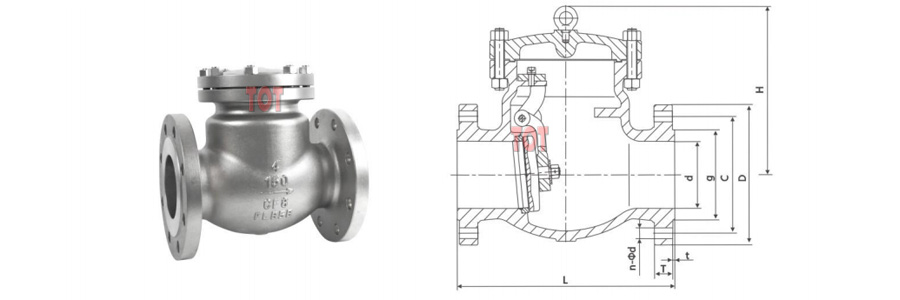

Main External and Connection Dimension

TOT Valve can provide you with API Swing Check Valve of various sizes and models. We list all existing API Swing Check Valve Sizes.

The data we provide can be used for your reference. If you do not have the swing check valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

Class 150LB API Swing Check Valve

| in | d | L | D | C | g | T | t | H | n-Φ |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 15 | 108 | 89 | 60.5 | 35 | 12 | 1.6 | – | 4-15 |

| 3/4″ | 20 | 117 | 98 | 70.0 | 43 | 12 | 1.6 | – | 4-15 |

| 1″ | 25 | 127 | 108 | 79.5 | 51 | 12 | 1.6 | – | 4-15 |

| 1-1/4″ | 32 | 140 | 117 | 89.5 | 64 | 13 | 1.6 | – | 4-15 |

| 1-1/2″ | 40 | 165 | 127 | 98.5 | 73 | 15 | 1.6 | – | 4-15 |

| 2″ | 50 | 203 | 152 | 120.5 | 92 | 16 | 1.6 | 161 | 4-19 |

| 2-1/2″ | 65 | 216 | 178 | 139.5 | 105 | 18 | 1.6 | 180 | 4-19 |

| 3″ | 80 | 241 | 190 | 152.5 | 127 | 19 | 1.6 | 190 | 4-19 |

| 4″ | 100 | 292 | 229 | 190.5 | 157 | 24 | 1.6 | 203 | 8-19 |

| 5″ | 125 | 330 | 254 | 216 | 186 | 24 | 1.6 | 229 | 8-22 |

| 6″ | 150 | 356 | 279 | 241.5 | 216 | 26 | 1.6 | 257 | 8-22 |

| 8″ | 200 | 495 | 343 | 298.5 | 270 | 29 | 1.6 | 292 | 8-22 |

| 10″ | 250 | 622 | 406 | 362 | 324 | 31 | 1.6 | 355 | 12-25 |

| 12″ | 300 | 698 | 483 | 432 | 381 | 32 | 1.6 | 396 | 12-25 |

| 14″ | 350 | 787 | 533 | 476 | 413 | 35 | 1.6 | 445 | 12-29 |

| 16″ | 400 | 864 | 597 | 540 | 470 | 37 | 1.6 | 490 | 16-29 |

| 18″ | 450 | 978 | 635 | 578 | 533 | 40 | 1.6 | 520 | 16-32 |

| 20″ | 500 | 978 | 698 | 635 | 584 | 43 | 1.6 | 546 | 20-32 |

| 24″ | 600 | 1295 | 813 | 749.5 | 692 | 49 | 1.6 | 880 | 20-35 |

| 26″ | 650 | 1295 | 786 | 744.5 | 711 | 41 | 1.6 | 910 | 36-22 |

| 28″ | 700 | 1448 | 837 | 795.5 | 762 | 44 | 1.6 | 935 | 40-22 |

| 30″ | 750 | 1524 | 887 | 846.0 | 813 | 44 | 1.6 | 970 | 44-22 |

Class 300LB API Swing Check Valve

| in | d | L | D | C | g | T | t | H | n-Φ |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 15 | 152 | 95 | 66.5 | 35 | 15 | 1.6 | – | 4-15 |

| 3/4″ | 20 | 178 | 117 | 82.5 | 43 | 16 | 1.6 | – | 4-19 |

| 1″ | 25 | 203 | 124 | 89 | 51 | 18 | 1.6 | – | 4-19 |

| 1-1/4″ | 32 | 216 | 133 | 98.5 | 63 | 19 | 1.6 | – | 4-19 |

| 1-1/2″ | 40 | 229 | 156 | 114.5 | 73 | 21 | 1.6 | – | 4-22 |

| 2″ | 50 | 267 | 165 | 127 | 92 | 22 | 1.6 | 178 | 8-19 |

| 2-1/2″ | 65 | 292 | 190 | 149 | 105 | 25 | 1.6 | 190 | 8-22 |

| 3″ | 80 | 318 | 210 | 168 | 127 | 29 | 1.6 | 216 | 8-22 |

| 4″ | 100 | 356 | 254 | 200 | 157 | 32 | 1.6 | 241 | 8-22 |

| 5″ | 125 | 400 | 279 | 235 | 186 | 35 | 1.6 | 267 | 8-22 |

| 6″ | 150 | 444 | 318 | 270 | 216 | 37 | 1.6 | 305 | 12-22 |

| 8″ | 200 | 533 | 381 | 330 | 270 | 41 | 1.6 | 368 | 12-25 |

| 10″ | 250 | 622 | 444 | 387.5 | 324 | 48 | 1.6 | 394 | 16-29 |

| 12″ | 300 | 711 | 521 | 451 | 381 | 51 | 1.6 | 445 | 16-32 |

| 14″ | 350 | 838 | 584 | 514.5 | 413 | 54 | 1.6 | 470 | 20-32 |

| 16″ | 400 | 864 | 648 | 571.5 | 470 | 57 | 1.6 | 533 | 20-35 |

| 18″ | 450 | 978 | 711 | 628.5 | 533 | 60 | 1.6 | 584 | 24-35 |

| 20″ | 500 | 1016 | 775 | 686 | 584 | 64 | 1.6 | 610 | 24-35 |

| 24″ | 600 | 1346 | 914 | 813 | 692 | 70 | 1.6 | 900 | 24-41 |

Class 600LB API Swing Check Valve

| in | d | L | D | C | g | T | t | H | n-Φ |

|---|---|---|---|---|---|---|---|---|---|

| 2″ | 50 | 292 | 165 | 127 | 92 | 33 | 6.4 | 203 | 8-19 |

| 2-1/2″ | 65 | 330 | 190 | 149 | 105 | 36 | 6.4 | 229 | 8-22 |

| 3″ | 80 | 356 | 210 | 168 | 127 | 39 | 6.4 | 235 | 8-22 |

| 4″ | 100 | 432 | 273 | 216 | 157 | 45 | 6.4 | 286 | 8-25 |

| 5″ | 125 | 508 | 330 | 266.5 | 186 | 52 | 6.4 | 292 | 8-29 |

| 6″ | 150 | 559 | 356 | 292 | 216 | 55 | 6.4 | 330 | 12-29 |

| 8″ | 200 | 660 | 419 | 349 | 270 | 63 | 6.4 | 381 | 12-32 |

| 10″ | 250 | 787 | 508 | 432 | 324 | 71 | 6.4 | 457 | 16-35 |

| 12″ | 300 | 838 | 559 | 489 | 381 | 74 | 6.4 | 584 | 20-35 |

| 14″ | 350 | 889 | 603 | 527 | 413 | 77 | 6.4 | 635 | 20-38 |

| 16″ | 400 | 991 | 686 | 603 | 470 | 84 | 6.4 | 684 | 20-41 |

| 18″ | 450 | 1092 | 743 | 654 | 533 | 90 | 6.4 | 752 | 20-44 |

| 20″ | 500 | 1194 | 813 | 724 | 584 | 96 | 6.4 | 975 | 24-44 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.