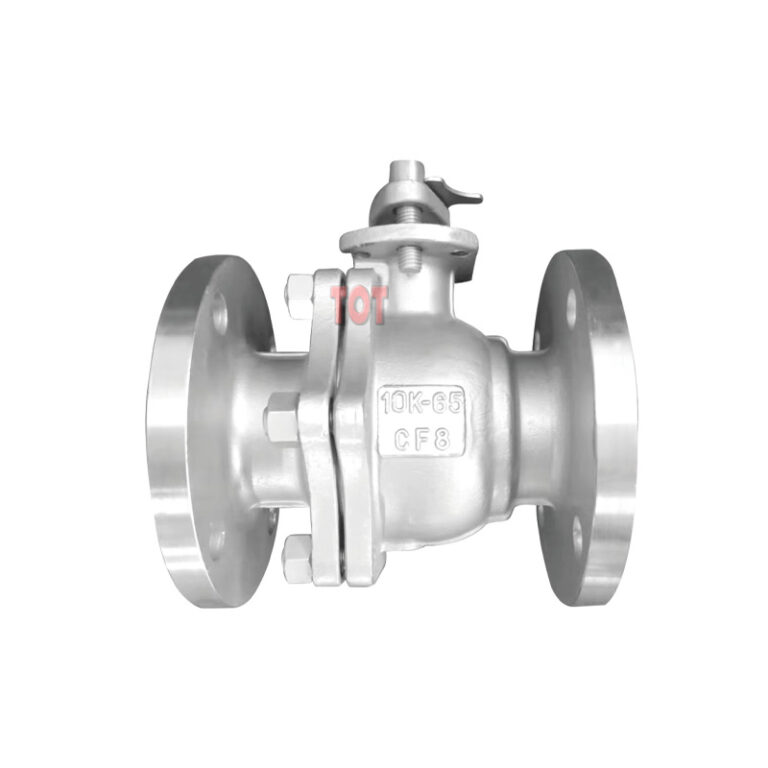

API 6D Floating Ball Valves

The API 6D Floating Ball Valves we produce are floating soft-sealed stainless steel ball valves that meet the API 6D standard. Made of high-quality stainless steel, you can use it to cut off or connect the media in the pipeline, including water, steam, oil, liquefied gas, natural gas, coal gas, acetic acid, oxidizing media, urea and other media.

We can provide you with a relatively complete range of industrial floating ball valves. If you need a floating ball valve solution for media such as oil and natural gas, TOT Valve is your ideal choice. Contact us now to get the most favorable ex-factory price.

Description

API 6D floating ball valves use a rotating ball and stem to provide on/off flow control. When you operate the hole of the valve in the same direction as the pipeline, the valve is in the open position and the fluid can flow downstream. When you rotate the ball 90 degrees, the hole is perpendicular to the flow channel, which means that the floating ball valve is closed and the fluid cannot flow downstream.

The floating ball design features a ball attached only to the valve stem, without using an energized valve seat. The line pressure causes the ball to move or “float” on the downstream valve seat, forming a positive seal that does not allow the medium to pass through. The floating ball provides a tight seal, even after long periods of use. Compared with other isolation valves, its design is very compact and is ideal for use in areas with limited space.

Floating Ball Valves Features

– Meets API 6D implementation standard

– Fireproof design and anti-drop valve stem

– Fully closed and fully opened by rotating 90 degrees, quick opening and closing

– Ball valve has minimal flow resistance

– The medium can flow through almost without loss

– The ball valve is small in size, light in weight, and easy to install in pipelines

– Competitive price

Materials of Floating Ball Valves

The TOT Valve body are cast or forged from a variety of high-quality materials, including stainless steel , cast steel and alloy steel, depending on the requirements of your floating ball valve application scenario.

The main materials of Packing are PTFE or Graphite.

If you are interested in our floating ball valve materials, you can contact us by leaving your information in the form on the right.

| Part | Material | ||

|---|---|---|---|

| Carbon Steel | CF8M | CF8 | |

| Body | A216-WCB | A351-CF8M | CF8 |

| Bonnet | A216-WCB | A351-CF8M | CF8 |

| Ball | A182-F3041 | A182-F316 | F304 |

| Stem | A276-304 | A276-316 | F304 |

| Seat Seat | R.PTFE | ||

| Gasket | Graphite+3042 | PTFE | PTFE |

| Valve Cover Bolt | A193-B7 | A193-B8M | A193-B8M |

| Valve Cover Nut | A194-2H | A194-8M | A194-8M |

| Packing | PTFE | ||

| Packing Press Plate | A216-WCB | CF8 | CF8 |

| Packing Bolt | A193-B7 | A193-B8M | A193-B8M |

| Positioning Sheet | Carbon Steel | F304 | F304 |

| Handle | Carbon Steel | ||

Notes: 1) A105+ENPoptional; 2) Spiral wound construction.

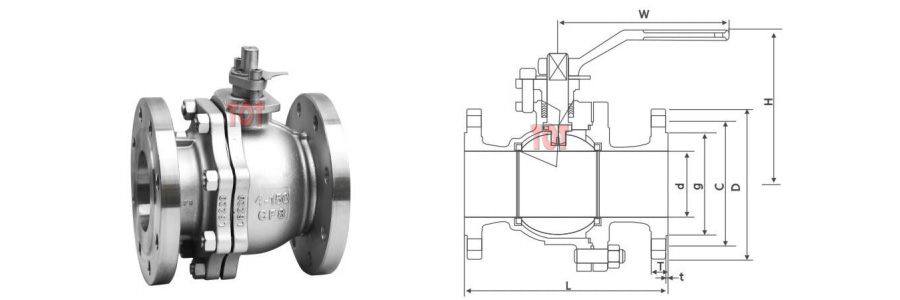

Floating Ball Valves Main Connection Dimensions

TOT Valve can provide you with API Floating Ball Valve of various sizes and models. We list all existing API floating ball valve sizes.

The data we provide can be used for your reference. If you do not have the floating ball valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

Class 150LB API Floating Ball Valves

| Size | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| in | d | L | D | C | g | T | t | H | W | n-Φ |

| 1/2″ | 15 | 108 | 89 | 60.5 | 35 | 12.7 | 1.6 | 87.5 | 142 | 4-15 |

| 3/4″ | 20 | 117 | 98 | 70.0 | 43 | 12.7 | 1.6 | 87.5 | 142 | 4-15 |

| 1″ | 25 | 127 | 108 | 79.5 | 51 | 13 | 1.6 | 91.5 | 142 | 4-15 |

| 1-1/4″ | 32 | 140 | 117 | 89 | 64 | 14.5 | 1.6 | 107 | 190 | 4-15 |

| 1-1/2″ | 40 | 165 | 127 | 98.5 | 73 | 15 | 1.6 | 128 | 200 | 4-15 |

| 2″ | 50 | 178 | 152 | 120.5 | 92 | 16 | 1.6 | 136 | 200 | 4-19 |

| 2-1/2″ | 65 | 190 | 178 | 139.5 | 105 | 18 | 1.6 | 158 | 300 | 4-19 |

| 3″ | 80 | 203 | 190 | 152.5 | 127 | 19 | 1.6 | 196 | 350 | 4-19 |

| 4″ | 100 | 229 | 229 | 190.5 | 157 | 24 | 1.6 | 212 | 700 | 4-19 |

| 5″ | 125 | 256 | 254 | 215.9 | 186 | 24 | 1.6 | 252 | 1100 | 8-22 |

| 6″ | 150 | 394 | 279 | 241.5 | 261 | 26 | 1.6 | 272 | 1100 | 8-22 |

| 8″ | 200 | 457 | 343 | 298.5 | 270 | 29 | 1.6 | 342 | 1500 | 8-22 |

| 10″ | 250 | 533 | 406 | 362 | 324 | 30 | 1.6 | 345 | 1500 | 12-25 |

| 12″ | 300 | 610 | 483 | 432 | 381 | 32 | 1.6 | 385 | – | 12-25 |

| 14″ | 337 | 686 | 535 | 476 | 413 | 35 | 1.6 | 430 | – | 12-29 |

| 16″ | 387 | 762 | 597 | 540 | 470 | 37 | 1.6 | 470 | – | 16-29 |

| 18″ | 489 | 914 | 698 | 635 | 582 | 43 | 1.6 | 590 | – | 16-32 |

Class 300LB API Floating Ball Valves

| Size | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| in | d | L | D | C | g | T | t | H | W | n-Φ |

| 1/2″ | 15 | 140 | 95 | 66.5 | 35 | 15 | 1.6 | 87.5 | 142 | 4-15 |

| 3/4″ | 20 | 152 | 117 | 82.5 | 43 | 16 | 1.6 | 87.5 | 142 | 4-15 |

| 1″ | 25 | 165 | 124 | 89.0 | 51 | 18 | 1.6 | 91.5 | 142 | 4-19 |

| 1-1/4″ | 32 | 178 | 133 | 98.5 | 64 | 19 | 1.6 | 107 | 190 | 4-19 |

| 1-1/2″ | 40 | 190 | 156 | 114.5 | 73 | 21 | 1.6 | 128 | 200 | 4-22 |

| 2″ | 50 | 216 | 165 | 127 | 92 | 23 | 1.6 | 136 | 200 | 8-19 |

| 2-1/2″ | 65 | 241 | 190 | 149 | 105 | 26 | 1.6 | 158 | 300 | 8-22 |

| 3″ | 80 | 283 | 210 | 168.5 | 127 | 29 | 1.6 | 202 | 350 | 8-22 |

| 4″ | 100 | 305 | 254 | 200 | 157 | 32 | 1.6 | 218 | 700 | 8-22 |

| 5″ | 125 | 381 | 279 | 235 | 186 | 35 | 1.6 | 252 | 1100 | 8-22 |

| 6″ | 150 | 403 | 318 | 270 | 216 | 37 | 1.6 | 272 | 1100 | 12-22 |

| 8″ | 200 | 502 | 381 | 330 | 270 | 41 | 1.6 | 342 | 1500 | 12-25 |

| 10″ | 250 | 568 | 444 | 387.5 | 324 | 48 | 1.6 | 345 | 1500 | 16-29 |

Class 600LB API Floating Ball Valves

| Size | Dimensions(mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| in | d | L | D | C | g | T | t | H | W | n-Φ |

| 1/2″ | 15 | 165 | 95 | 66.5 | 35 | 15 | 6.4 | 59 | 160 | 4-16 |

| 3/4″ | 20 | 190 | 117 | 82.5 | 43 | 16 | 6.4 | 63 | 160 | 4-19 |

| 1″ | 25 | 216 | 124 | 89.0 | 51 | 18 | 6.4 | 75 | 230 | 4-19 |

| 1-1/4″ | 32 | 229 | 133 | 98.5 | 64 | 21 | 6.4 | 85 | 300 | 4-19 |

| 1-1/2″ | 40 | 241 | 156 | 114.5 | 73 | 22.3 | 6.4 | 95 | 400 | 4-22 |

| 2″ | 50 | 292 | 165 | 127 | 92 | 25.4 | 6.4 | 107 | 700 | 8-19 |

| 4 | 100 | 432 | 273 | 216 | 157.2 | 38 | 6.4 | 178 | 1100 | 8-25 |

| 5″ | 125 | 491 | 330 | 267 | 186 | 44.5 | 6.4 | 225 | 1100 | 8-29 |

| 6″ | 152 | 559 | 356 | 282 | 216 | 47.2 | 6.4 | 250 | 1500 | 12-29 |

| 8″ | 203 | 660 | 419 | 349 | 282 | 55.7 | 6.4 | 294 | 1500 | 12-32 |

* We are not just providing simple quotes but experts in selection, calculation, and drawing.