Wafer Ceramic Lined Gate Valve

TOT pneumatic wafer ceramic lined gate valve is a single/double sided sealing with anti-wear gate valve, high-quality structural ceramic seals (alumina, zirconium oxide), hardness up to 60~90 HRC, with excellent mechanical and wear resistance. Our design is designed to solve the problem of short service life caused by continuous impact of sealing surface wear and compressed air mixing, material erosion.

If you need our ceramic gate valve, please contact us immediately.

Description

The wafer ceramic lined gate valve, also known as ceramic gate valve, is a valve with structural ceramic lining for ceramic-ceramic sealing.

In order to solve your limited installation space, we can also provide you with wafer-type valves.

Our skilled technicians carefully grind and polish all the ceramic sealing surfaces of the ceramic lined gate valve to ensure that the leakage of your conveying system reaches the V level specified in FCI 70-2.

The pneumatic ceramic gate valve we provide has a structural ceramic lining in the valve body, which helps you to achieve stable and excellent wear resistance in particle conveying systems such as dry ash conveying systems and hopper pumps.

Most customers who buy our ceramic valves use them in high-wear and corrosion-resistant industries such as mining, papermaking, and chemicals. While ensuring its service life, it saves you operating costs.

Design Standard of Ceramic Lined Gate Valve Implemented by TOT Valve

| Nominal Pressure | Design and Manufacture | Face-to-Face Dimension | Flange Dimension | Inspection and Test | Material Standard | Valve Testing |

|---|---|---|---|---|---|---|

| PN10/16, ANSI Class 150LB/300LB | GB/T 12224, ASME B16.34 | Manufacturers Standard, ASME B16.5 & B16.47 | JB/T 79.1, ANSI B16.5, DIN 2543, JIS B2020 | GB/T 9092, ASME B16.34 | GB/T 12229 for Carbon Steel, GB/T 12230 for Stainless Steel | API 598 |

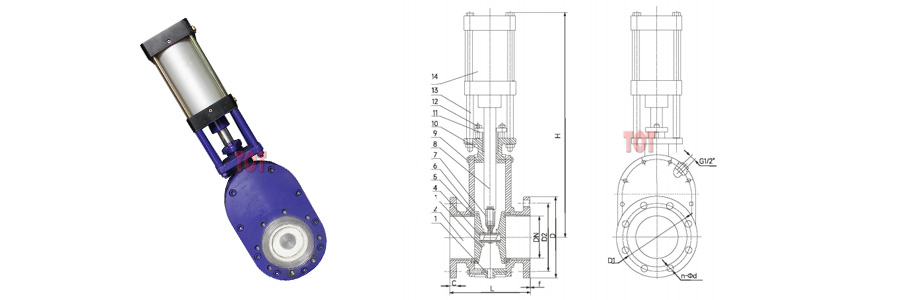

Structural Features of Pneumatic Ceramic Lined Gate Valves

- Cylinder actuator: Use a cylinder to drive the gate up and down to quickly open/close

- Double gate: Use floating connection to provide reliable single/two-way sealing. Floating connection helps to evenly distribute friction and extend service life

- Wear-resistant ceramics: The sealing surface is lined with wear-resistant ceramics, which has excellent wear resistance and corrosion resistance

- Structural design: easy to transport, install and maintain

- Working temperature: up to 450℃

- Competitive price

Main Component Materials

| Number | Name | Material | Number | Name | Material |

|---|---|---|---|---|---|

| 1 | Main Body | WCB | 8 | Piston Rod | 45# Chrome Plated |

| 2 | Side of Body | WCB | 9 | Screw the valve body | B7 |

| 3 | Ram | WCB | 10 | Packing | PTFE |

| 4 | Disc Spring | 50CrVA | 11 | Packing Gland Set | WCB |

| 5 | Seat | Engineering Ceramics | 12 | Pressure Set of Bolt | B7 |

| 6 | Ram Lining | Engineering Ceramics | 13 | Cylinder Pillar | Q235 Galvanized |

| 7 | Gate Frame | WCB | 14 | Cylinder | Aluminum Alloy |

Main Appearance and Connection Dimensions

| Size | L | D | D1 | D2 | C | f | H | n-Φd | |

|---|---|---|---|---|---|---|---|---|---|

| DN | In | ||||||||

| 50 | 2 | 240 | 165 | 125 | 100 | 16 | 3 | 480 | 4-18 |

| 65 | 2-1/2 | 260 | 185 | 145 | 120 | 18 | 3 | 520 | 4-18 |

| 80 | 3 | 260 | 200 | 160 | 135 | 20 | 3 | 560 | 4-18 |

| 100 | 4 | 280 | 220 | 180 | 155 | 20 | 3 | 650 | 4-18 |

| 125 | 5 | 300 | 250 | 210 | 185 | 22 | 3 | 790 | 4-18 |

| 150 | 6 | 300 | 285 | 240 | 210 | 22 | 3 | 790 | 8-22 |

| 200 | 8 | 310 | 340 | 295 | 265 | 24 | 3 | 968 | 8-22 |

| 250 | 10 | 365 | 395 | 350 | 320 | 26 | 3 | 1090 | 12-23 |

| 300 | 12 | 400 | 445 | 400 | 368 | 26 | 4 | 1260 | 12-23 |

Working Principle of Pneumatic Ceramic Lined Gate Valve

When compressed air enters from the upper air inlet, the valve stem of the pneumatic ceramic lined gate valve drives the valve plate to move downward and the valve is closed.

When air enters from the lower air inlet, the valve stem drives the valve plate to move upward, and the pneumatic ceramic lined gate valve opens.

A spring is added between the valve plate and the valve seat to ensure that they are always tightly closed, while allowing the valve plate to move vertically smoothly.

Such a design can compensate for the thermal expansion and contraction of the pneumatic ceramic lining, overcome the influence of fluctuating back pressure on the seal, and prevent granular media from entering the sealing surface.

During the opening and closing process, the valve plate can rotate by itself, thereby grinding and polishing the sealing surface.

Since the inlet and outlet passages are offset from the center of the pneumatic ceramic lined gate valve body, vortices are generated, which automatically purge the valve cavity.

All these features contribute to the valve’s extra-long service life and provide reliable guarantee for your system.

* We are not just providing simple quotes but experts in selection, calculation, and drawing.