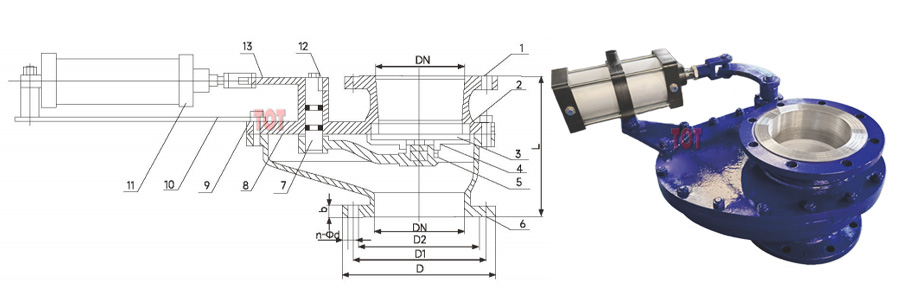

Ceramic Swing Feed Valve

Ceramic Swing Feed Valve is a special valve used to control the flow of feed containing abrasive media (such as dry powder, slurry, mineral powder, etc.). It adopts ceramic sealing and ceramic lining structure, combined with swing opening and closing mechanism design. It is mostly used in power plant desulfurization system, dry ash handling system, pneumatic conveying equipment or intermediate feed points in mineral processing.

Contact us now to get competitive market prices.

Ceramic Swing Feed Valve Description

The ceramic swing feed valve is a purpose-engineered valve solution for feeding and discharging highly abrasive materials such as fly ash, mineral slurry, and desulfurization by-products. Designed for long-cycle performance and high-frequency operation, this valve integrates aswing-type flow control mechanism with ceramic-lined sealing surfaces, making it ideal for use in aggressive environments commonly found in power plants, mining, and chemical process industries.

The ceramic valves we provide are trusted by original equipment manufacturers (OEMs) and engineering general contractors (EPCs) in the power, mining and process fields. If you are one of them and are interested in purchasing valves from China, please contact us now.

Executive Standards

| Design and Manufacturing | Flange Connection | Inspection and Testing | Structure Length |

|---|---|---|---|

| API 6D | GB/T9113 | GB/T13927 | Manufacturers standards or customer requirements |

Ceramic Swing Feed Valve Features

– Ceramic Lined Flow Path: All critical flow-contact surfaces are lined with high-purity alumina or zirconia ceramics, offering excellent resistance to wear, erosion, and corrosion.

– Swing-Type Closure: The swing disc or flap design enables smooth opening/closing, minimizing the risk of jamming caused by solid particles.

– Precision Sealing Surface: The ceramic sealing face is finely ground for enhanced shut-off performance and prolonged lifecycle.

– Robust Construction: Valve body fabricated from carbon steel or stainless steel, with wall thickness exceeding standard specifications.

– Actuator: The ceramic swing feed valve is pneumatic actuator operated, and we can also provide you with standard manual and electric actuator operated ceramic valves.

– Modular design allows for quick replacement of ceramic components and minimizes downtime

Main Component Materials

| Number | Name | Material |

|---|---|---|

| 1 | Main Valve Body | WCB |

| 2 | Bonnet | WCB |

| 3 | Cylinder | Aluminum Alloy |

| 4 | Spring | 50 CrVA |

| 5 | Valve Plate | WCB + Engineering ceramics |

| 6 | Valve Seat | Engineering Ceramics |

| 7 | Disc Holder | WCB |

| 8 | Axle | 45# |

| 9 | Double Headed Studs | 35 CrMoVA |

| 10 | Nut | 25 |

Main Appearance and Connection Dimensions (Unit: mm)

| Size | PN | L | D | D1 | D2 | b | n-Φd | |

|---|---|---|---|---|---|---|---|---|

| DN | In | |||||||

| 80 | 3″ | 10 | 230 | 200 | 160 | 132 | 20 | 8-18 |

| 100 | 4″ | 250 | 220 | 180 | 156 | 20 | 8-18 | |

| 125 | 5″ | 265 | 250 | 210 | 184 | 22 | 8-22 | |

| 150 | 6″ | 265 | 285 | 240 | 211 | 24 | 8-22 | |

| 200 | 8″ | 310 | 340 | 295 | 266 | 24 | 8-22 | |

| 250 | 10″ | 395 | 405 | 350 | 319 | 26 | 12-26 | |

| 300 | 12″ | 450 | 460 | 400 | 370 | 28 | 12-26 | |

| 350 | 14″ | 500 | 520 | 460 | 429 | 30 | 16-26 | |

Ceramic Swing Feed Valve Working Principle

- The valve flap is swung open or closed by pneumatic control;

- When open, it allows the material to fall or enter the next process;

- When closed, it strictly blocks the flow of materials;

- Ceramic components effectively cope with high-abrasion and high-frequency opening and closing occasions.

* We are not just providing simple quotes but experts in selection, calculation, and drawing.