PFA Lined Butterfly Valve

PFA lined butterfly valves are butterfly valves that have a layer of PFA (Polyfluoroalkoxy) material covering the media-contacting parts of the butterfly valve disc and valve body to improve its corrosion resistance and sealing performance.

Our PFA lined butterfly valves provide you with a reliable solution for controlling media flow in environments with corrosive chemicals, high temperatures or abrasives.

We offer PFA lined butterfly valves in a variety of sizes, pressure ratings and configurations to meet your specific application needs. We place great emphasis on product quality, durability and reliability to provide you with the best long-term solution.

Explore our impressive range of PFA lined butterfly valves now!

TOT Valve provides you with a smooth PFA lining surface, which forms an effective barrier between the media and the metal shell, thereby improving corrosion and wear resistance and minimizing deposits and clogging. This can extend the service life of the butterfly valve and minimize potential downtime.

The sizes of PFA butterfly valves we produce are various, ranging from 1-½ inches to 28 inches (DN40-DN700). You can apply PFA butterfly valves to oil, oil and gas, water treatment, wastewater treatment and other industrial applications.

Below we have summarized some data about the specifications, materials, sizes and other aspects of PFA lined butterfly valves for you, hoping to help you choose the right lined butterfly valve.

PFA Lined Butterfly Valve Specifications and Standards

| Size | 40mm-700mm (1½ ” to 28″) |

| Working Pressure | 0.1mbar-10bar |

| Temperature Range | -29℃ ~ 260℃ according to working conditions, other temperatures on request. |

| Design & Manufacture | APl609 DIN EN1092 JIS B2032 |

| Face to Face | ASME B16.10, DIN EN558. 1, JIS B2002 |

| Flange Ends | ASME B16.5 DIN 2532 JIS B2212 (150LB, 10K, PN10) |

| Visual Inspection | MSS Sp54 |

| Testing | API 598, DIN 3230, JIS B2003 |

| Pressure & Temperature | ASME B16.34 |

| Operator Type | Lever/ Gear/ Pneumatic/ Electric |

| Spark Testing | 14kv |

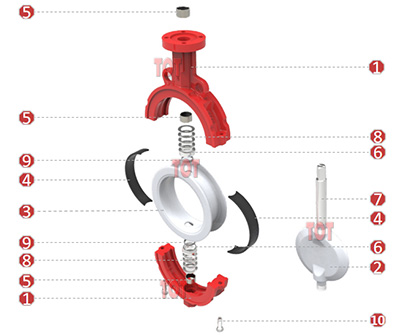

PFA Lined Butterfly Valve Parts

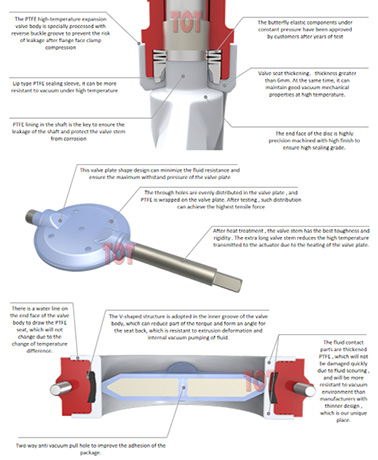

At TOT Valve, PFA lined butterfly valve’s special feature is the valve seat has an independent triangular gasket sealing ring.

PFA lining in the shaft is the key to ensure the leakage of the shaft and protect the valve stem from corrosion

The butterfly elastic components under constant pressure have been approved by customers after years of test

Valve seat thickening,thickness greater than 6mm. At the same time, it can maintain good vacuum mechanical properties at high temperature.

The end face of the disc is highly precision machined with high finish to ensure high sealing grade.

This valve plate shape design can minimize the fluid resistance and ensure the maximum withstand pressure of the valve plate

The through holes are evenly distributed in the valve plate , and PFA is wrapped on the valve plate. After testing , such distribution can achieve the highest tensile force

After heat treatment , the valve stem has the best toughness and rigidity . The extra long valve stem reduces the high temperature transmitted to the actuator due to the heating of the valve plate.

There is a water line on the end face of the valve body to draw the PFA seat, which will not change due to the change of temperature difference.

The V-shaped structure is adopted in the inner groove of the valve body, which can reduce part of the torque and form an angle for the seat back, which is resistant to extrusion deformation and internal vacuum pumping of fluid.

The fluid contact parts are thickened PFA , which will not be damaged quickly due to fluid scouring , and will be more resistant to vacuum environment than manufacturers with thinner design , which is our unique place.

Two way anti vacuum pull hole to improve the adhesion of the package.

PFA Lined Butterfly Valve Materials

| NO. | Description | Materials | Materials According to Norms | |||

| ASTM | JIS | DIN | ||||

| 1 | BODY | Carbon Steel, Stainless Steel, Ductile lron | A216-WCB, A351-CF8, ASTM A395 | G5151 SCPH2, G5121 SCS13A, FCD400 | GS-45(1 .0446), G-X6CrNiMo1810, GGG-40 (0.7040) | |

| 2 | DISC | Carbon Steel, Stainless Steel | PTFE, FEP, PFA | A216-WCB, A351-CF8 | G5151 SCPH2, G5121 SCS13A | GS–45(1.0446), G-X6CrNiMo1810 |

| 3 | SEAT | PTFE/FEP/PFA | — | — | — | |

| 4 | ELASTIC SPACER | EPDM | — | — | — | |

| 5 | AXLE SLEEVE | Stainless Steel + PTFE | — | — | — | |

| 6 | Gland | Stainless Steel | 304 | SUS304 | 1.4301 | |

| 7 | STEM | Stainless Steel | 410, 304 | SUS410, SUS304 | 1.4006, 1.4301 | |

| 8 | BELLEVILLE SPRING | Stainless Steel | 304 | SUS304 | 1.4301 | |

| 9 | V-RING | PTFE | — | — | — | |

| 10 | HEX BOLT | Stainless Steel | 304 | SUS304 | 1.4301 | |

*PFA Service Temperature: -40°~+200°; Excellent chemical resistance and temperature resistance.

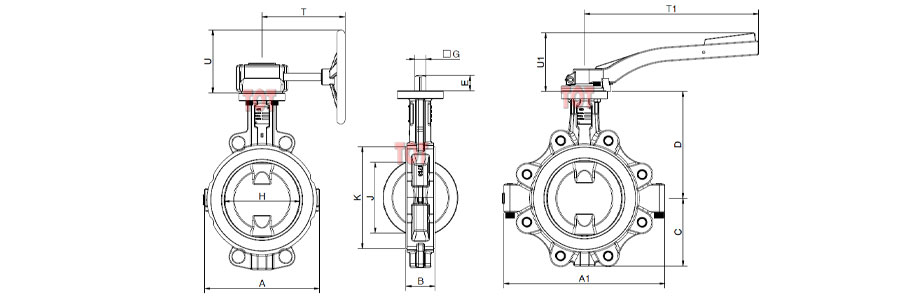

Wafer & Lug Type PFA Lined Butterfly Valve Dimension

| DN | NPS | Dimensions in mm | ISO 5211 | Weight | Cv | Torque | ||||||||||||||||

| Wafer | Lug | Handle | Gearbox | |||||||||||||||||||

| mm | in | A | A1 | B | C | D | E | G | H | J | K | T | T1 | U | U1 | [Kg] | [Kg] | [Kg] | [Kg] | [N∙m] | ||

| 40 | 1½ | 91 | 146 | 33 | 55 | 109 | 13 | 11 | 40.5 | 23.5 | 78 | 160 | 200 | 95 | 76 | F05 | 2.5 | 3.2 | 0.45 | 1.6 | 190 | 35 |

| 50 | 2 | 102 | 159 | 43 | 65 | 134.5 | 13 | 11 | 50.5 | 26.5 | 89.5 | 160 | 200 | 95 | 76 | F05 | 3 | 4.7 | 0.45 | 1.6 | 210 | 40 |

| 65 | 2½ | 118 | 204 | 46 | 74 | 149 | 13 | 11 | 65.5 | 46.5 | 104.5 | 160 | 200 | 95 | 76 | F05 | 3.4 | 5.8 | 0.45 | 1.6 | 300 | 48 |

| 80 | 3 | 135 | 226 | 46 | 84 | 156 | 13 | 11 | 79.5 | 65 | 121.5 | 160 | 200 | 95 | 76 | F05 | 4 | 6.5 | 0.45 | 1.6 | 410 | 56 |

| 100 | 4 | 158 | 260 | 52 | 100 | 179 | 16 | 14 | 98.5 | 84 | 144 | 160 | 260 | 127 | 85 | F07 | 5.8 | 8.5 | 0.65 | 1.8 | 710 | 82 |

| 125 | 5 | 184 | 289 | 56 | 116 | 194 | 19 | 17 | 120.5 | 107 | 168.5 | 160 | 350 | 127 | 102 | F07 | 7.6 | 10.6 | 0.8 | 1.8 | 1150 | 120 |

| 150 | 6 | 214 | 315 | 56 | 132 | 209 | 19 | 17 | 146.5 | 136 | 196.5 | 160 | 350 | 127 | 102 | F07 | 10 | 13.9 | 0.8 | 1.8 | 1750 | 170 |

| 200 | 8 | 270 | 383 | 60 | 164 | 237.5 | 24 | 22 | 195.5 | 186 | 251.5 | 215 | – | 153 | – | F10 | 16.7 | 17.9 | – | 3 | 3550 | 298 |

| 250 | 10 | 330 | 456 | 68 | 195 | 275 | 24 | 22 | 245.5 | 236 | 305.5 | 225 | – | 185 | – | F10 | 24 | 27.2 | – | 5 | 5100 | 390 |

| 300 | 12 | 384 | 528 | 78 | 222 | 300 | 29 | 27 | 292.5 | 282 | 354.5 | 325 | – | 248 | – | F12 | 32 | 35.8 | – | 10 | 8870 | 590 |

| 350 | 14 | 448 | 570 | 78 | 258 | 325 | 29 | 27 | 343.5 | 334 | 408.5 | 325 | – | 248 | – | F12 | 57 | 87 | – | 10 | 9200 | 810 |

| 400 | 16 | 510 | 652 | 102 | 294 | 365 | 38 | 36 | 392 | 378.5 | 459 | 230 | – | 217 | – | F14 | 69 | 101 | – | 18.5 | 14500 | 1260 |

| 450 | 18 | 602 | 672 | 114 | 314 | 400 | 38 | 36 | 446 | 431 | 516 | 230 | – | 217 | – | F14 | 82 | 137 | – | 18.5 | 20100 | 1470 |

| 500 | 20 | 657 | 721 | 127 | 351 | 444 | 38 | 36 | 489 | 472 | 569 | 335 | – | 285 | – | F16 | 96 | 158 | – | 41 | 22000 | 1800 |

| 600 | 24 | 766 | 852 | 154 | 410 | 510 | 48 | 46 | 588 | 567 | 669 | 335 | – | 285 | – | F16 | 141 | 242 | – | 41 | 31000 | 2995 |

| 700 | 28 | 906 | 992 | 165 | 454 | 553 | 57 | 55 | 699.5 | 679 | 780 | 385 | – | 310 | – | F25 | 182 | 290 | – | 52 | 39500 | 3400 |

*The weight of the wafer and lug type is bare shaft

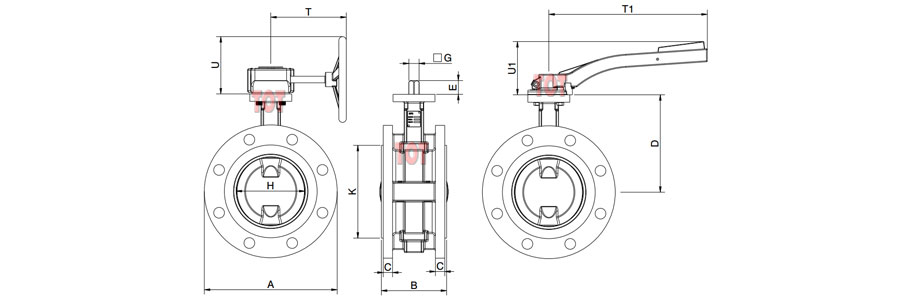

Flanged Type PFA Lined Butterfly Valve Dimension

| DN | NPS | Dimensions in mm | ISO 5211 | Weight | Cv | Torque | ||||||||||||||||

| PN10 | PN16 | Double Flanged | Handle | Gearbox | ||||||||||||||||||

| mm | in | A | C | A | C | B | D | E | ☐G | H | K | T | T1 | U | U1 | [Kg] | [Kg] | [Kg] | [N∙m] | |||

| 40 | 1½ | 150 | 16 | 150 | 16 | 106 | 109 | 13 | 11 | 40.5 | 78 | 160 | 200 | 95 | 76 | F05 | 10.7 | 0.45 | 1.6 | 190 | 35 | |

| 50 | 2 | 165 | 16 | 165 | 16 | 108 | 134.5 | 13 | 11 | 50.5 | 89.5 | 160 | 200 | 95 | 76 | F05 | 16 | 0.45 | 1.6 | 210 | 40 | |

| 65 | 2½ | 185 | 16 | 185 | 16 | 112 | 149 | 13 | 11 | 65.5 | 104.5 | 160 | 200 | 95 | 76 | F05 | 19.1 | 0.45 | 1.6 | 300 | 48 | |

| 80 | 3 | 200 | 18 | 200 | 18 | 114 | 156 | 13 | 11 | 79.5 | 121.5 | 160 | 200 | 95 | 76 | F05 | 24 | 0.45 | 1.6 | 410 | 56 | |

| 100 | 4 | 220 | 18 | 220 | 18 | 127 | 179 | 16 | 14 | 98.5 | 144 | 160 | 260 | 127 | 85 | F07 | 30 | 0.65 | 1.8 | 710 | 82 | |

| 125 | 5 | 250 | 20 | 250 | 20 | 140 | 194 | 19 | 17 | 120.5 | 168.5 | 160 | 350 | 127 | 102 | F07 | 35.3 | 0.8 | 1.8 | 1150 | 120 | |

| 150 | 6 | 285 | 20 | 285 | 20 | 140 | 209 | 19 | 17 | 146.5 | 196.5 | 160 | 350 | 127 | 102 | F07 | 51.8 | 0.8 | 1.8 | 1750 | 170 | |

| 200 | 8 | 340 | 22 | 340 | 22 | 152 | 237.5 | 24 | 22 | 195.5 | 251.5 | 215 | – | 153 | – | F10 | 65.5 | – | 3 | 3550 | 298 | |

| 250 | 10 | 395 | 24 | 405 | 24 | 165 | 275 | 24 | 22 | 245.5 | 305.5 | 225 | – | 185 | – | F10 | 88.7 | – | 5 | 5100 | 390 | |

| 300 | 12 | 445 | 23 | 460 | 25 | 178 | 300 | 29 | 27 | 292.5 | 354.5 | 325 | – | 248 | – | F12 | 107.9 | – | 10 | 8870 | 590 | |

| 350 | 14 | 505 | 23 | 520 | 27 | 190 | 325 | 29 | 27 | 343.5 | 408.5 | 325 | – | 248 | – | F12 | 166.4 | – | 10 | 9200 | 810 | |

| 400 | 16 | 565 | 23 | 580 | 29 | 216 | 365 | 38 | 36 | 392 | 459 | 230 | – | 217 | – | F14 | 200.5 | – | 18.5 | 14500 | 1260 | |

| 450 | 18 | 615 | 25 | 640 | 37 | 222 | 400 | 38 | 36 | 446 | 516 | 230 | – | 217 | – | F14 | 289.7 | – | 18.5 | 20100 | 1470 | |

| 500 | 20 | 670 | 24 | 715 | 40 | 229 | 444 | 38 | 36 | 489 | 569 | 335 | – | 285 | – | F16 | 366 | – | 41 | 22000 | 1800 | |

| 600 | 24 | 780 | 30 | 840 | 50 | 267 | 510 | 48 | 46 | 588 | 669 | 335 | – | 285 | – | F16 | 466 | – | 41 | 31000 | 2995 | |

* The weight of the double flanged type is bare shaft

* We are not just providing simple quotes but experts in selection, calculation, and drawing.