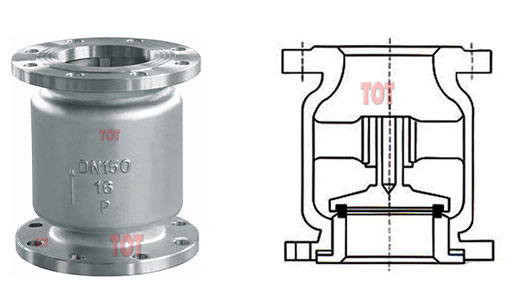

Vertical Lift Check Valve

When backflow prevention is mission-critical in your vertical pipelines, you need a valve engineered for uncompromised performance and durability. Our Stainless Steel Flanged Vertical Lift Check Valve is your go-to solution for preventing reverse flow in process lines handling water, oil, steam, or aggressive chemicals.

Built for vertical upward flow only, this lift-type non-return valve combines precise engineering with long-lasting stainless steel construction to ensure reliable sealing under a wide range of industrial applications.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

Designed to operate without external actuation, the vertical lift check valve uses gravity and a spring-loaded disc to allow forward flow and automatically seal against reverse flow. The disc moves vertically within the valve body and seats tightly when back pressure occurs, minimizing wear and preventing water hammer.

This flanged check valve is made of SS304 or SS316 stainless steel, making it ideal for corrosive media, hygienic processes, or outdoor installations. It’s designed in accordance with ASME, API, and DIN standards, ensuring seamless integration into your piping systems.

Whether you are replacing an existing check valve or specifying components for a new installation, this stainless steel vertical check valve offers performance you can trust.

Get a quote now and let us help you find the right vertical lift check valve for your application in the shortest possible time.

Vertical Lift Check Valve Features

- One-Way Vertical Flow Control – Suitable only for upward flow in vertical pipelines

- Lift-Type Internal Disc – Ensures quick closing and low leakage

- Corrosion-Resistant Construction – Available in SS304 or SS316 for harsh media

- Full Port Design – Reduces flow resistance, increases Cv

- Standardized Flanged Ends – Compatible with ANSI, DIN, or JIS connections

- Spring-Loaded Closure – Improves response time and protects system from surges

- Low Maintenance – No need for external controls, actuation, or frequent adjustment

Main Technical Parameters & Performance

| Size Range | DN50-DN1200 (2″ – 48″) |

| Connection Options | Flange |

| Working Pressure | 1.0MPa-1.6MPa |

| Working Temperature | -53°C to 148°C |

| Sealing Options | PTFE, Graphite |

| Manufacturing Method | Forging, Carbon Steel |

| Manufacturing Standard | ANSI, ASME, GB |

| Applicable Medium | Oil, Gas, Water |

Main Components and Materials

| Part | Material |

| Body | WCB, CF8, CF8M, CF3, CF3M |

| Flow Guide | Cast Iron, Ductile Iron, Carbon Steel |

| Seat | Bronze, Chrome Stainless Steel |

| Disc | WCB, CF8, CF8M, CF3, CF3M |

| Axis | Bronze, Chrome Stainless Steel |

| Spring | Stainless Steel |

Vertical Lift Check Valve Dimensions

TOT valve can provide you with various sizes of vertical lift check valve. We have listed some vertical lift check valve for DN300-DN1200 for your reference.

If you don’t have the vertical lift check valve you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Diameter | D1 | D2 | D3 | N-ΦD | L | ||||||

| DN | In | 1.0 MPa | 1.6 MPa | 1.0 MPa | 1.6 MPa | 1.0 MPa | 1.6 MPa | 1.0 MPa | 1.6 MPa | ||

| DN300 | 12″ | 370 | 400 | 410 | 460 | 12-13 | 12-28 | 181 | |||

| DN350 | 14″ | 429 | 460 | 470 | 520 | 16-23 | 16-28 | 184 | |||

| DN400 | 16″ | 480 | 515 | 525 | 580 | 16-28 | 16-31 | 191 | |||

| DN450 | 18″ | 530 | 565 | 585 | 640 | 20-28 | 20-31 | 203 | |||

| DN500 | 20″ | 582 | 620 | 650 | 715 | 20-28 | 20-34 | 219 | |||

| DN600 | 24″ | 682 | 725 | 770 | 810 | 840 | 20-31 | 20-37 | 222 | ||

| DN700 | 28″ | 794 | 840 | 840 | 895 | 910 | 24-31 | 24-37 | 280 | ||

| DN800 | 32″ | 901 | 950 | 950 | 1015 | 1025 | 24-34 | 24-40 | 356 | ||

| DN900 | 36″ | 1001 | 1050 | 1050 | 1125 | 1125 | 28-40 | 28-40 | 368 | ||

| DN1000 | 40″ | 1112 | 1160 | 1170 | 1230 | 1255 | 28-43 | 28-43 | 432 | ||

| DN1200 | 48″ | – | 1380 | 1390 | 1455 | 1485 | 32-49 | 32-49 | 524 | ||

Applications That Require High Reliability

This vertical lift type stainless steel check valve is engineered for systems where flow integrity and corrosion resistance cannot be compromised:

- Water Treatment Facilities – Prevents contaminated backflow into clean water lines

- Chemical Processing Plants – Handles corrosive and hazardous media

- Boiler & Steam Lines – Withstands thermal expansion and thermal cycling

- Petrochemical & Oil Pipelines – Offers safety in explosive environments

- Pharmaceutical, Food & Beverage – Complies with hygienic requirements

- HVAC & Utility Systems – Prevents pump damage from back pressure surges

Wherever you need a vertical non-return valve that performs consistently, our solution is built to deliver.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.