Wafer Lift Check Valve

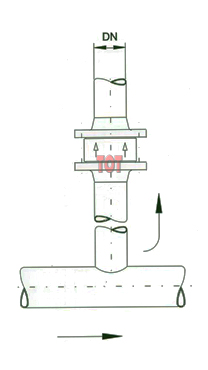

The wafer lift check valve you are considering consists of high-quality stainless steel body, disc, spring and other core components. You can install it on horizontal or vertical pipes to effectively prevent medium backflow. Its short end face structure, compact size and lightweight design make it easy to integrate into your system without taking up valuable space.

If you need a reliable and space-saving backflow prevention device, the wafer lift check valve is your preferred solution. Designed for harsh industrial applications, this valve ensures efficient unidirectional flow and fast response even in low-pressure systems. Whether you are operating in chemical, water treatment or power generation environments, this compact and powerful valve can give you peace of mind.

Contact us now to get the best ex-factory wafer type lift check valve prices.

Description

Wafer lift check valve also known as wafer type lift check valve, wafer spring check valve or wafer type spring loaded check valve.

We can provide you with wafer lift check valves that meet ANSI/API/JIS/DIN standards, and you can choose the configuration that meets the corresponding standards according to the specific project needs. Because the disc is corrosion-resistant spring-loaded, the valve can be closed quickly, thereby minimizing water hammer pressure. The smooth internal flow channel reduces fluid resistance and improves the efficiency of your application system. Its fast response speed and reliable sealing performance ensure the long-term stable operation of the valve.

This wafer type lift check valve features a streamlined body that fits snugly on standard flanges, allowing for easy installation and precise alignment. It is a perfect blend of simplicity, reliability and performance – all in a wafer body that minimizes installation space.

TOT Wafer lift check valve is very suitable for clean media, not recommended for pipelines containing solid particles or high viscosity fluids. By choosing different materials of wafer lift check valves, you can apply them to media such as water, steam, oil, nitric acid, acetic acid, strong oxidants, uric acid, etc. Our customers widely use them in petrochemical, metallurgy, power generation, light industry, food processing and other industries.

Get a quote now and let us help you find the right wafer type spring loaded check valve for your application in the shortest possible time.

Wafer Lift Check Valve Features

- Wafer-style design for tight installation spaces

- Full stainless-steel options for superior corrosion resistance

- Short structure length, Small size and light weight

- Spring-loaded disc ensures fast closure to prevent water hammer

- Vertical lift mechanism provides low friction, the sealing performance is good and quick operation

- Can be installed in both horizontal and vertical lines

- Minimal cracking pressure, ideal for systems with low starting pressure

- The service life is long and the reliability is high, low-maintenance structure with minimal moving parts

- Competitive Prices

Main Technical Parameters & Performance

| Product Name | Wafer Lift Check Valve | Body Material | CF8, CF8M, CF3M, WCB or Customized Materials |

| Connection Method | Wafer Type | Nominal Diameter | DN15-DN200(1/2″-8″) |

| Nominal Pressure | 1.0 Mpa-16 Mpa (150LB-900LB) | Applicable Media | Water, air, oil, chemical fluids |

| Applicable Temperature | -40℃~425℃ | Design Criteria | API 594; API 6D; |

| Structure Length | API 594; API 6D; DIN 3202; | Pressure Temperature | ASME B16.34; DIN2401; GB/T12224 |

| Inspection & Testing | API 598, GB/T26480 | Manufacturing Standards | GB, ANSI, API, JIS, DIN or Other standard customization |

Main Components and Materials

| Component | Material Options |

| Body | CF8 / CF8M / CF3M / WCB |

| Disc | SS304 / SS316 |

| Spring | Stainless Steel |

| Seat | Metal / Soft Seat (EPDM, NBR, PTFE) |

| Guide Bushing | PTFE or Bronze |

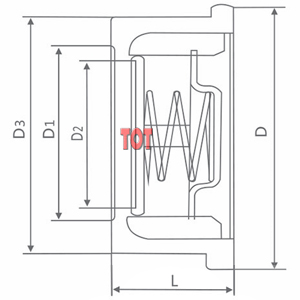

Wafer Type Lift Check Valve Dimensions

| Dimensions | Size(mm) | Piping Flange (For Reference) | ||||||

| DN | In | L | d | A | Bolt Hole Diameter D1 | Number of Bolts | Bolt Diameter D | Bolt Length L1 |

| 15 | 1/2″ | 16 | 45 | 18 | 65 | 4 | M12 | 75 |

| 20 | 3/4″ | 19 | 55 | 25 | 75 | 4 | M12 | 90 |

| 25 | 1″ | 22 | 65 | 32 | 85 | 4 | M12 | 90 |

| 32 | 1-1/4″ | 28 | 78 | 38 | 100 | 4 | M16 | 100 |

| 40 | 1-1/2″ | 32 | 85 | 45 | 110 | 4 | M16 | 105 |

| 50 | 2″ | 40 | 100 | 57 | 125 | 4 | M16 | 125 |

| 65 | 2-1/2″ | 46 | 120 | 73 | 145 | 4 | M16 | 130 |

| 80 | 3″ | 50 | 135 | 89 | 160 | 8 | M16 | 135 |

| 100 | 4″ | 60 | 155 | 108 | 180 | 8 | M16 | 150 |

| 125 | 5″ | 90 | 185 | 133 | 210 | 8 | M16 | 180 |

| 150 | 6″ | 106 | 210 | 159 | 240 | 8 | M20 | 240 |

| 200 | 8″ | 140 | 265 | 219 | 295 | 12 | M20 | 260 |

*More sizes available upon request.

Applications That Require High Reliability

Your operations demand efficiency without compromise. This wafer spring check valve is engineered to deliver exactly that. It’s ideal for:

- Water supply and drainage systems

- HVAC systems

- Chemical and petrochemical processing

- Power generation facilities

- Food and beverage industries

- Fire protection pipelines

By choosing our wafer type spring loaded check valve, you’re investing in stable, maintenance-friendly performance that reduces downtime and protects your systems from costly reverse flow damage.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.