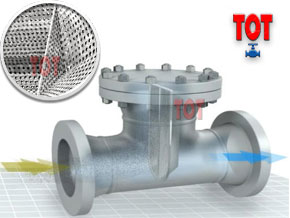

Fabricated Tee Strainers

When your pipeline system demands uninterrupted flow and protection from debris, a fabricated tee strainer (also known as a Tee-type Strainer or T-type Strainer ) is the solution you can count on. Designed for high dirt-holding capacity, easy access maintenance, and low pressure drop, this fabricated tee strainer is built for performance in critical applications.

Ideal for applications where Y-strainers fall short, especially in high solid-loading systems, the fabricated tee strainer offers the filtration efficiency and structural integrity required by today’s demanding industrial operations.

Contact us now to get the best ex-factory fabricated tee strainer prices.

Description

A T-type strainer is a pipeline strainer installed horizontally or vertically to remove unwanted solid particles from the process stream. Compared to Y-type strainers, the T-type is preferred when greater debris volumes must be captured and retained, or when solid particle recovery is needed.

Our fabricated strainers are constructed using seamless pipes, carbon or stainless steel plate, or standard equal tee fittings with flanges. The straining element consists of perforated stainless steel sheets or wire mesh reinforced with perforated support—engineered for durability and corrosion resistance.

For added strength, the basket is supported by a skeleton made from flat bar and round bar sections. Depending on your operational needs, you can select from bolted covers or quick-opening closures for faster maintenance turnaround.

The fabricated tee strainer is a cost-effective solution for filtration at large nominal pipe diameters, supporting both custom design and standard ANSI/DIN requirements.

Get a quote now and let us help you find the right T strainer for your application in the shortest possible time.

Fabricated Tee Strainer Features

- Custom-Fabricated Steel Construction — Tailored to meet your system specifications and built from heavy-duty CS or SS plates and pipe.

- Inline Basket Orientation — Optimized flow-through design reduces turbulence and pressure loss.

- Large Surface Filtration Area — Extended basket depth and diameter allow for high-volume debris capture, minimizes downtime.

- High-Performance Mesh Options — Perforated sheet, mesh-lined, or wedge wire construction based on your filtration rating, supports mesh from 40 to 500 microns.

- Robust Mechanical Support — Internal skeleton improves rigidity and operational lifespan under high flow velocities.

- Maintenance-Friendly Access — Choose between bolted or quick-open cover for convenient basket removal and cleaning.

- Threaded or Flanged Vent/Drain Connections — Standard on all models for safe and easy system purging or sampling.

Main Technical Parameters & Performance

| Specification | Details |

| Pipe Size Range | 2” to 48” (DN50 – DN1200) |

| Design Pressure Ratings | ANSI 150#, 300#, 600#, 900#, or per application |

| Flow Direction | Horizontal or Vertical inline |

| Mesh Rating | 1/32” perforation up to 1000 micron mesh (custom available) |

| Basket Material | SS304 / SS316 perforated, mesh-reinforced, or wedge wire |

| Body Material | Carbon Steel, Stainless Steel (304, 316), others on request |

| Max Operating Temp | Up to 800°F / 425°C (depending on seal and material selection) |

| Connections | Flanged (RF/RTJ), Butt Weld, Socket Weld |

| Cover Type | Bolted cover or quick-opening hinged/clamp type |

| Design Standard | ASME B31.1 / B31.3, EN 13445, PED, NACE MR0175, API 614 (where applicable) |

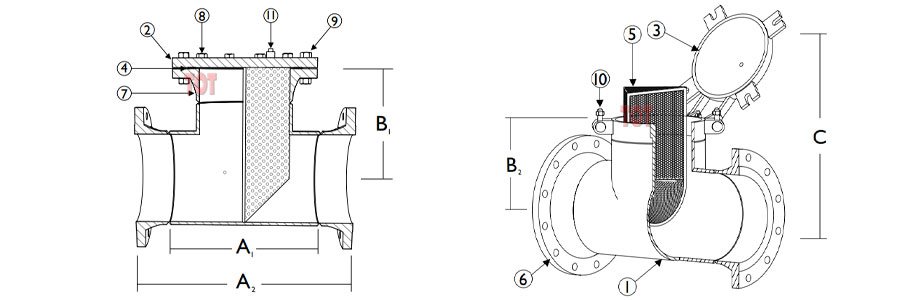

Main Components and Materials

| Component | Material Options |

| Body | CF8, CF8M,CF3M,WCB, Duplex (optional) |

| Filter Basket | SS304 / SS316 |

| Gasket/Seal | Graphite, PTFE, Spiral Wound SS + Graphite/Viton/Buna |

| Cover | Matching body material with lifting lugs |

| Drain/Vent Ports | ½” NPT or flanged; with optional plug or valve |

| Bolting & Nuts | Zinc-coated CS or SS304/316 depending on application |

Fabricated Tee Strainers Dimension

| Size | Face to Face(mm) | Ctr-Line to Top(mm) | C (mm) | |||

|---|---|---|---|---|---|---|

| DN | In | A₁ | A₂ | B₁ | B₂ | |

| 50 | 2″ | 127 | 273 | 137 | – | 303 |

| 65 | 2-1/2″ | 152 | 311 | 157 | – | 348 |

| 80 | 3″ | 172 | 337 | 168 | – | 381 |

| 100 | 4″ | 210 | 387 | 194 | – | 446 |

| 125 | 5″ | 248 | 451 | 225 | – | 522 |

| 150 | 6″ | 286 | 489 | 245 | 252 | 573 |

| 200 | 8″ | 356 | 584 | 292 | 294 | 694 |

| 250 | 10″ | 432 | 673 | 337 | 354 | 810 |

| 300 | 12″ | 508 | 775 | 387 | 403 | 937 |

| 350 | 14″ | 559 | 851 | 426 | 446 | 1029 |

| 400 | 16″ | 610 | 908 | 454 | 483 | 1111 |

| 450 | 18″ | 686 | 1010 | 505 | 546 | 1238 |

| 500 | 20″ | 762 | 1092 | 546 | 608 | 1346 |

*Exact dimensions vary depending on strainer size, pressure class, and connection type. We can provide full dimensional drawings and CAD files according to your specific requirements.

Applications That Require High Reliability

Our custom fabricated T strainers are trusted in high-stakes environments where particle contamination is not an option. From protecting heat exchangers to extending pump life, this unit is ideal for:

- Petrochemical and Oil & Gas Pipelines

- Power Generation Systems (Condensate, Cooling Water)

- Desalination and Water Treatment Plants

- Chemical & Pharmaceutical Processing

- Pulp & Paper Production Lines

- Marine & Offshore Fluid Handling

- District Heating & Steam Distribution

TOT Valve Get a Custom Solution for Your Piping System! Every flow system is unique—and so is every fabricated tee-type strainer we build. Request a Quote!

FAQ

What is a Fabricated “T” Strainer and how does it work?

A Fabricated “T” Strainer, also known as a Tee-Type Strainer, is a custom-built pipeline filtration device designed to remove debris and particulates from fluid systems. It features a T-shaped body with a removable strainer basket positioned perpendicular to the flow path. As fluid passes through the strainer, solid contaminants are captured in the basket, preventing damage to downstream equipment such as pumps, valves, and meters.

When should I choose a T-Type Strainer over a Y-Strainer?

T-Type Strainers are ideal for applications requiring high-capacity filtration and low-pressure drop. They are preferred over Y-Strainers when:

- The system handles large volumes of debris.

- Frequent maintenance or cleaning is anticipated.

- A lower pressure drop is desired.

- The application involves horizontal pipeline installations.

Y-Strainers, while more compact, have a smaller debris-holding capacity and may not be suitable for systems with high particulate loads.

Can T-Type Strainers be installed vertically?

While T-Type Strainers are primarily designed for horizontal installations, certain models can be installed vertically, provided that the flow direction and basket orientation are appropriate. However, vertical installation may complicate maintenance and basket removal. It’s essential to consult the manufacturer’s guidelines and ensure that the design accommodates vertical installation if required.

How often should the strainer basket be cleaned?

The cleaning frequency of a strainer basket depends on factors such as:

- The amount and type of debris in the system.

- Operating conditions and flow rates.

- System criticality and maintenance schedules.

Some systems incorporate differential pressure gauges or taps to monitor the pressure drop across the strainer, indicating when cleaning is necessary. Regular inspection and maintenance schedules should be established based on operational experience and manufacturer recommendations.

Are there quick-opening cover options available for T Strainers?

Yes, many Fabricated T Strainers offer quick-opening cover designs, such as hinged or clamped closures. These features allow for faster access to the strainer basket, reducing downtime during maintenance and cleaning operations. The choice between bolted and quick-opening covers depends on factors like maintenance frequency, safety requirements, and operational preferences.

Can T-Type Strainers be used in high-temperature or high-pressure applications?

Fabricated T Strainers can be designed to withstand high-temperature and high-pressure conditions by selecting appropriate materials and construction methods. For instance:

High-Temperature Applications: Utilizing materials like stainless steel and high-temperature gaskets (e.g., graphite) allows operation in elevated temperatures.

High-Pressure Applications: Designing the strainer body and components to meet specific pressure ratings (e.g., ANSI 600#, 900#) ensures safe operation under high-pressure conditions.

It’s crucial to specify the operating conditions during the design phase to ensure the strainer meets the application’s requirements.

What maintenance practices are recommended for T Strainers?

Recommended maintenance practices for T Strainers include:

- Regular Inspection: Monitor pressure drop and inspect for signs of clogging or damage.

- Scheduled Cleaning: Establish cleaning intervals based on system conditions and debris load.

- Basket Replacement: Replace or repair damaged baskets to maintain filtration efficiency.

- Seal Inspection: Check gaskets and seals for wear and replace as necessary to prevent leaks.

- Documentation: Maintain records of maintenance activities for compliance and performance tracking.

Adhering to these practices ensures the strainer operates effectively and prolongs its service life.

How do select the appropriate T Strainer for you application?

Selecting the right T Strainer involves considering several factors:

- Flow Rate: Ensure the strainer can handle the system’s flow requirements.

- Operating Pressure and Temperature: Choose materials and designs suitable for the system’s conditions.

- Debris Characteristics: Understand the type and size of particulates to select the appropriate mesh size.

- Maintenance Needs: Consider features like quick-opening covers for ease of maintenance.

- Installation Constraints: Account for space limitations and orientation requirements.

Consulting with manufacturers or engineering professionals can aid in selecting a strainer that meets your specific needs.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.