Stainless Steel Bellows Expansion Joint

Reliable Flexibility for High-Performance Piping Systems

Are you looking for a durable and flexible solution to manage thermal expansion, vibration and misalignment in your piping system? Our stainless steel bellows expansion joints are precisely engineered to handle the toughest industrial conditions, ensuring you reduce system stress, prevent equipment failure, and extend the life of your infrastructure.

Our OEM and custom expansion joints are used in a wide range of industries including oil and gas, aerospace, power generation, petrochemical, water supply and wastewater treatment.

Ready to upgrade? Request a quote today. Let’s build the perfect expansion joint for your system.

Description

Stainless steel bellows expansion joint also known as stainless steel expansion bellows or stainless steel flexible bellows, it’s a flexible component installed in piping systems to absorb thermal movement, reduce vibration, and compensate for minor misalignments.

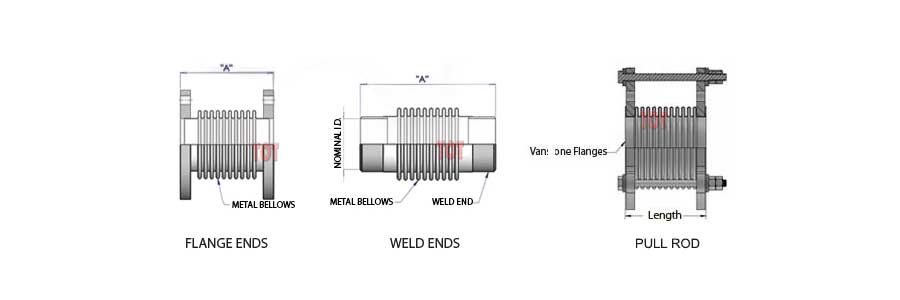

The stainless steel bellows expansion joints we offer are usually composed of corrugated stainless steel bellows elements with flange ends or welded sleeve ends for you to integrate into your system.This design allows you to maintain the structural integrity of your piping while accommodating temperature changes and mechanical stress.

Made from premium stainless steel grades such as SS304, SS316L, and SS321, our bellows offer excellent corrosion resistance and mechanical strength, making them suitable for high-temperature, high-pressure, and chemically aggressive environments.

TOT Valve is a reliable stainless steel bellows manufacturer and supplier that can not only provide you with stainless steel expansion bellows of various types, materials and sizes, but also customize them according to your requirements. Contact us now and let us support your business.

Stainless Steel Bellows Expansion Joint Features

Multi-directional movement absorption (axial, lateral, angular)

High-grade stainless steel (SS304 / SS316L / SS321) construction

Leak-proof design for critical applications

Flanged, welded, or threaded end connections available

Compact structure and easy installation

Maintenance-free under standard operating conditions

Optional inner sleeves, pull rods, and external covers for enhanced protection

Core Advantages at a Glance

| Feature | Stainless Steel Bellows | Rubber Joints | Carbon Steel Expansion Joints |

|---|---|---|---|

| Temperature Resistance | Up to 800°C | Up to 120°C | Up to 450°C |

| Service Life | 10+ Years | 1–3 Years | 3–5 Years |

| Corrosion Resistance | Excellent | Low | Moderate |

| Pressure Capability | High | Low | Medium |

| Maintenance Requirements | Minimal | Frequent | Occasional |

| Suitable for Critical Systems | Yes | No | Limited |

Main Components and Materials

Bellows Core: Formed from seamless stainless steel sheets (SS316L recommended for aggressive media)

End Connections: Weld neck flanges, slip-on flanges, or beveled ends in carbon steel or stainless steel

Inner Sleeve (optional): Prevents internal turbulence and protects the bellows from abrasion

Pull Rods / Control Rods (optional): Limit excess movement and balance internal pressure

External Cover (optional): Guards against mechanical damage and thermal loss

Technical Specifications & Performance

| Parameter | Range / Value |

|---|---|

| Nominal Diameter (DN) | DN25 to DN1000; 1″ ~ 40″ |

| Pressure Rating (PN) | PN6 to PN64 (up to 1500 psi) |

| Operating Temperature | -200°C to 800°C |

| Movement Type | Axial ±10–50 mm, Lateral ±5–25 mm |

| End Connections | Flanged, Welded, Threaded |

| Bellows Material | SS304, SS316L, SS321 |

| Liner / Cover (Optional) | Stainless steel / carbon steel |

| Standards | ASME, EJMA, EN, GB |

*Custom sizes and movement ranges are available upon request.

Applications That Require High Reliability

You can rely on stainless steel bellows expansion joints for performance in:

- Thermal pipelines in power plants

- Chemical processing lines handling corrosive fluids

- Steam and condensate return systems

- Oil & gas transfer lines and refineries

- HVAC systems in commercial and industrial buildings

- Desalination and water treatment facilities

- Shipbuilding and marine exhaust systems

Wherever pipeline movement must be controlled under high stress, these bellows are your go-to solution.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.