Metal Expansion Joint Weld End

Precision-Welded Flexibility for High-Performance Piping Systems

When you’re working with high-pressure, high-temperature, or high-vibration systems, the reliability of every welded connection matters. Our metal expansion joints with weld ends provide durable, leak-proof compensation for axial, lateral, and angular movement—seamlessly integrated into your pipeline via butt weld connections.

Whether you’re designing for steam, thermal oil, gas, or corrosive chemical systems, this is the solution you can count on for long-term structural integrity and zero leakage.

Description

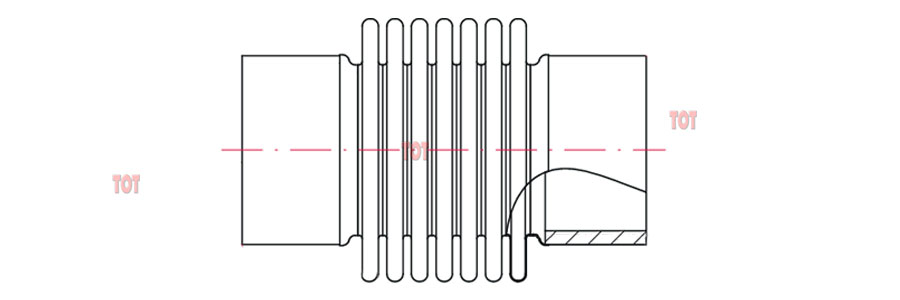

A metal expansion joint with weld ends is a flexible connector consisting of a stainless steel bellows element with butt-weldable pipe ends. Unlike flanged joints, this design eliminates potential leak paths from gaskets and bolted connections, making it ideal for high-purity, high-pressure, or fully welded pipeline systems.

The bellows absorb thermal expansion, vibration, and pipe misalignment, while the weld ends ensure strong, permanent integration into your process line.

Metal Expansion Joint Weld End Features

- Butt-Weld End Connections – Permanent, secure installation

- All-Metal Bellows Construction – High pressure & temperature performance

- Leak-Free Operation – No flanges, no gaskets, no external sealing

- Custom-Engineered Movement Capabilities – Axial, lateral, angular flexibility

- Compact Design – Space-saving and pipeline-integrated

- Material Flexibility – Stainless steel, Inconel, Hastelloy, and more

Materials & Options

| Component | Material Options |

|---|---|

| Bellows | SS304, SS316L, Inconel 625, Hastelloy C276 |

| Weld Ends | Same grade as pipeline, beveled for welding |

| Liner Sleeve | Optional (for flow efficiency/protection) |

Technical Parameters & Performance

- Size Range (DN): DN25 to DN1000

- Operating Pressure: Up to 40 bar (depends on size & ply)

- Temperature Range: –200°C to +600°C

- Movement Types: Axial, Lateral, Angular

- Axial Compression: ±10 mm to ±50 mm

- Cycle Life: Up to 10,000+ full expansion cycles

- Testing Standards: EN 14917, EJMA, ASME B31.3, PED on request

Core Advantages at a Glance

| Feature | Benefit to You |

|---|---|

| Fully Welded Design | Zero leakage, even under extreme loads |

| High Pressure & Temperature Rated | Reliable for demanding systems |

| Compact & Clean Connection | Ideal for cleanrooms or confined spaces |

| Long Lifespan | Fewer shutdowns and replacements |

| No Bolts or Gaskets | Lower maintenance, no retightening |

| Available in Multi-Ply Bellows | Greater flexibility and cycle life |

Common Applications

Metal expansion joints with weld ends are your best choice when your system requires permanent, zero-leak connections with high reliability:

- Steam and Thermal Oil Pipelines

- High-Pressure Gas or Air Systems

- Boiler and Turbine Outlets

- Chemical Processing Pipelines

- Cryogenic or Superheated Fluids

- Welded Stainless Piping Networks

- Skid Units and Compact Modules

They are widely used in industries such as power generation, petrochemical, aerospace, semiconductors, and cleanroom manufacturing.

FAQ

Why choose weld ends over flanged ends?

Weld ends eliminate potential leak points from flanges and gaskets, making them ideal for high-pressure, high-purity, or vibration-prone systems.

Can I specify the same weld end material as my pipeline?

Absolutely. We match weld ends to your pipeline grade (e.g., SS316L, Inconel, etc.) to ensure perfect weld compatibility.

Are these joints compliant with ASME or PED?

Yes. We design and test to EN, ASME, and PED standards upon request, with full documentation and CE marking available.

What movement range can expect?

Axial movement typically ranges from ±10–50 mm depending on size and design. We also support custom lateral and angular movement configurations.

Do you offer multi-ply bellows?

Yes, multi-ply designs are available for improved flexib

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.