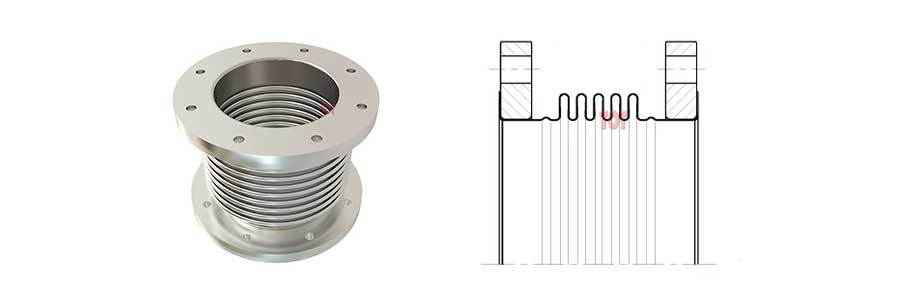

Flanged Metal Expansion Joint

Flexible, Pressure-Rated, and Maintenance-Friendly – Built for Industrial Piping Demands

When your industrial pipeline system requires movement compensation with fast, flanged installation, a metal expansion joint with flanged ends is the go-to solution. Whether you’re dealing with thermal stress, pump vibration, or misaligned pipework, this flanged bellows expansion joint provides a durable, flexible, and leak-proof solution that integrates directly with your bolted connections.

Our flanged metal bellows expansion joints are engineered for durability, built to international standards, and ready for rapid delivery.

Description

This flanged metal bellows expansion joint consists of a corrugated stainless steel bellow designed to absorb multi-directional movement. It is terminated with welded flanges on both ends, enabling secure bolted installation to pumps, valves, tanks, or adjacent pipelines.

Ideal for high-temperature, high-pressure, and corrosive service conditions, these steel expansion joints with flanges are widely used in steam lines, chemical plants, and HVAC systems.

Made from premium stainless steel grades such as SS304, SS316L, our bellows offer excellent corrosion resistance and mechanical strength, making them suitable for high-temperature, high-pressure, and chemically aggressive environments.

TOT is a reliable expansion joint manufacturer and supplier that can not only provide you with stainless steel expansion bellows of various types, materials and sizes, but also customize them according to your requirements. Contact us now and let us support your business.

Flanged Metal Expansion Joint Features

Standardized Flanged Ends – ANSI, DIN, JIS drilling available

All-Metal Flexible Construction – Resists pressure, temperature, and corrosion

Absorbs Thermal Expansion and Mechanical Stress

Easy Installation and Future Replacement

Custom Movement Compensation – Axial, lateral, angular flexibility

Multi-Ply Bellows Available – Enhanced fatigue life and flexibility

Flanged Metal Expansion Joint Material Specifications

| Component | Material Options |

|---|---|

| Bellows | SS304, SS316L, Inconel 625, Hastelloy C276 |

| Flanges | Carbon Steel, SS304, SS316, PTFE-coated Steel |

| Gaskets (Optional) | PTFE, graphite, spiral wound, metal ring gaskets |

| Inner Sleeves (Optional) | Stainless Steel, PTFE (abrasion/corrosion protection) |

| External Covers (Optional) | Galvanized steel, SS304 (weather/damage protection) |

| Pull Rods / Limiters (Optional) | Optional for motion control and protection |

Technical Parameters & Performance

Nominal Diameter: DN25 – DN1000 (1″ – 40″)

Pressure Rating: Up to 40 bar (customizable)

Temperature Range: –200°C to +600°C

Movement Types: Axial ±10–60 mm / Lateral up to 30 mm / Angular up to 15°

Cycle Life: >10,000 full expansion cycles (with multi-ply bellows)

Standards: EJMA, EN 14917, ASME B31.3, PED-compliant upon request

Face-to-Face Length: Can be customized according to your system requirements

Applications That Require High Reliability

These stainless steel flanged expansion joints are trusted across industries where flexibility and sealing integrity are critical:

- Chemical & Petrochemical Pipelines

- Steam, Condensate & Thermal Oil Systems

- Power Plant Boilers & Heat Exchangers

- Water Treatment & Desalination Facilities

- HVAC Systems (Hot/Chilled Water Lines)

- Pumps, Turbines, Compressors

- Tank and Vessel Connections

You can also apply it to industrial pipe compensators, flange flexible joints in modular skid-mounted systems, and high-temperature pipe expansion bellows.

FAQ

What standards do your flanges follow?

ANSI B16.5 (150/300), DIN EN 1092-1 (PN10/16), JIS 10K, or customized drilling upon request.

Can I install this on a steam or hot oil system?

Yes, these high-temperature expansion joints are designed to handle up to 600°C in continuous operation.

Is gasket sealing required?

Yes, flanged connections require gaskets. We provide PTFE, graphite, or metallic options depending on your media and pressure class.

What’s the difference between single-ply and multi-ply bellows?

Multi-ply bellows offer greater flexibility, lower spring rate, and better fatigue resistance, ideal for cyclic systems.

Do you offer internal sleeves or flow liners?

Absolutely. For abrasive, high-velocity, or turbulent flow, internal liners protect the bellows and enhance flow stability.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.