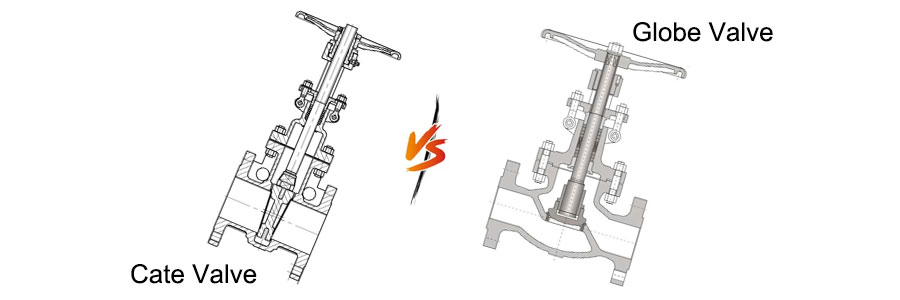

In industrial piping systems, selecting the right valve type is crucial for maintaining efficiency, safety, and control. Two of the most commonly compared valve types are globe valves and gate valves—both widely used, yet fundamentally different in design and function.

If you’re wondering which one is better suited for your application, this article provides a side-by-side breakdown, hope to help you make an informed choice.

PS: TOT valve is committed to providing excellent products and services to help you build high-quality solutions for fluid control systems. You are welcome to advisory our product catalog for more product information through enquiry@okvalveservice.com. You can also visit our okvalveservice.com site to get more resources about high-quality valves and their applications.

Table of Contents

ToggleWhat Is a Globe Valve and Gate Valve?

Globe Valve:It is a linear motion control valve used to regulate the flow in a pipeline. Its name comes from the traditional spherical shape of the valve body, though modern versions may feature straight or angle patterns. The globe valve uses a plug (disc) that moves perpendicular to the seat, allowing precise control of flow rate. This makes it ideal for applications where flow throttling and frequent adjustments are required.

Gate Valve: It is also a linear motion valve, but it’s designed primarily for on/off control. It uses a wedge-shaped gate that lifts vertically out of the path of the fluid. When the gate is fully raised, it provides an unobstructed, straight-through flow path with minimal pressure drop. Gate valves are not intended for throttling. Operating them partially open can lead to vibration, erosion, and long-term damage.

How Do They Work? (Principle & Flow Path)

Globe Valve Working Principle

The stem moves the disc vertically down to sit on the seat and stop flow.

When opened, fluid flows through an S-shaped path around the disc.

This tortuous path creates a pressure drop but allows accurate flow regulation.

Gate Valve Working Principle

The gate moves straight up or down to block or open the flow.

In the open position, fluid flows in a straight line, minimizing resistance.

Not suitable for partial opening or flow control.

Differences: Globe Valves vs. Gate Valves

Flow Control & Pressure Drop

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Flow Regulation | Excellent – ideal for throttling | Poor – designed for on/off |

| Pressure Drop | High due to S-shaped flow path | Low due to straight path |

Sealing & Shutoff Capabilities

Gate valves offer a tight seal, especially when fully closed, making them a good option for isolation applications.

Globe valves also offer reliable shutoff, though they are generally not bidirectional unless specifically designed for it.

Material Options and Size Range

Both valve types are available in a wide range of materials and pressure ratings:

| Main Component | Common Materials |

|---|---|

| Valve Body | Cast iron, WCB, stainless steel, bronze |

| Trim | 304/316 stainless steel, alloy steel |

| Seat & Packing | PTFE, metal-seated, graphite, EPDM |

PS: At TOT Valve we only select high-quality materials as raw materials. The stainless steel globe valves, stainless steel gate valves and stainless steel knife gate valves we provide you can meet international standards and guarantee your service life. Globe valves are more commonly used in small to medium pipe diameters. Gate valves are suitable for larger-diameter lines due to lower flow resistance.

Installation & Maintenance

Globe valves are easier to maintain due to accessible seating surfaces and top-entry design.

They can typically be installed in any direction, though upright positioning is preferred.

Gate valves, especially larger ones, may be more difficult to service due to their bulkier internals and longer stem travel.

Pros and Cons at a Glance

| Type | Advantages | Disadvantages |

|---|---|---|

| Globe Valve | Excellent for regulating flow; Faster opening/closing; Easy to repair and maintain | Higher pressure drop; Slightly more expensive; Less effective in full open/close applications |

| Gate Valve | Minimal pressure loss; Cost-effective for on/off use; Suitable for large-bore systems | Poor throttling capability; Slower to operate; Prone to seat erosion if not fully open |

Where, When to Use They?

Use a Globe Valve When:

- You need to adjust flow frequently (e.g., steam systems, cooling loops).

- Pressure drop is acceptable in favor of control.

- You’re dealing with smaller line sizes.

Use a Gate Valve When:

- You require a full open/close operation.

- Minimal pressure loss is a priority.

- You’re working with large-diameter pipelines.

Globe Valve vs Gate Valve Quick Comparison

After all the above, do you still have any questions? Here is a side-by-side overview of the main differences between globe valves and gate valves compiled by TOT Valve to help you consolidate and determine which valve is best for your system requirements.

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Primary Function | Flow regulation (throttling) | Full open/close isolation |

| Flow Path | S-shaped, more restrictive | Straight-through, minimal resistance |

| Pressure Drop | Higher | Lower |

| Control Precision | Excellent | Poor (not for throttling) |

| Shutoff Seal | Good | Excellent (when fully closed) |

| Opening Speed | Faster | Slower |

| Best for | Steam, cooling water, precise control loops | Water, oil, gas isolation systems |

| Maintenance Access | Easier (top entry) | Moderate |

| Typical Size Range | Small to medium pipelines | Medium to large pipelines |

| Installation Position | Horizontal or vertical | Usually horizontal |

How to Choose Gate Valve and Globe Valve?

Do you need flow regulation? Choose a globe valve.

Do you need minimal flow resistance? Choose a gate valve.

Are you space constrained? Globe valves typically require less vertical clearance.

Do you operate frequently? Globe valves are better suited for frequent use.

Whether it complies with international certification implementation standards, such as API, ANSI, ISO, DIN.

Still unsure? Consider pressure rating, fluid type, temperature, and maintenance requirements when making your final decision.

PS: TOT Valve As a professional industrial valve manufacturer, we select the right valve type based on your actual system needs. Our team often sees globe valves used in chemical metering, steam pressure control, and chiller systems, while gate valves are mainly used in oil and gas, water distribution, and tank isolation.

Conclusion

In the comparison of globe valve vs gate valve, there’s no one-size-fits-all answer. Each serves a distinct purpose. If precision and control are key, go with a globe valve. If you’re after simplicity and low resistance for on/off service, the gate valve is your best bet.

FAQ

In which applications are globe valves preferred over gate valves?

Globe valves are preferred in applications requiring precise flow control, such as in cooling systems, fuel oil systems, and feedwater systems. Their ability to regulate flow makes them ideal for these scenarios.

Can a globe valve be used for isolation purposes?

Yes, globe valves can be used for isolation; however, they are more commonly employed for flow regulation. While they can shut off flow, gate valves are typically preferred for isolation due to their lower pressure drop and full-bore design.

Why do globe valves have higher pressure drops compared to gate valves?

Globe valves have a tortuous flow path, causing the fluid to change direction within the valve body. This design leads to higher pressure drops. Gate valves, with their straight-through flow path, offer minimal resistance when fully open.

Are gate valves suitable for throttling applications?

TOT Valve does not recommend gate valves for throttling. Partially opening a gate valve can cause vibration, corrosion, and damage to the seat surface. Globe valves are more suitable for throttling due to their design and flow characteristics.

What are the maintenance considerations for globe and gate valves?

Globe valves, with their top-entry design, allow for easier maintenance and repair without removing the valve from the pipeline. Gate valves may require more extensive disassembly, especially in larger sizes or buried installations.