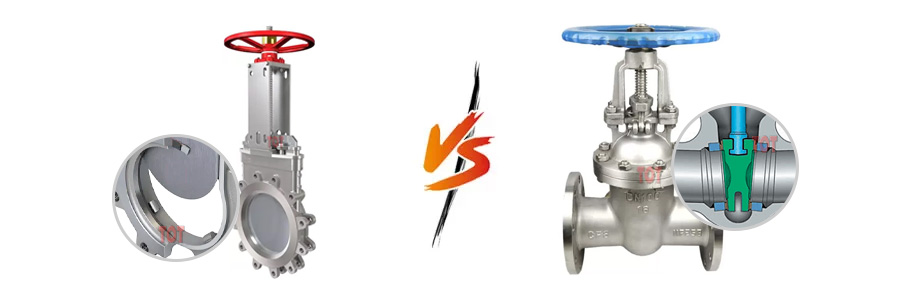

For industrial fluid control piping systems, choosing the right valve directly affects the efficiency, maintenance workload, and overall operating costs of the system. Among the many types of valves, knife gate valves and gate valves are two of the most commonly used but often misunderstood valves.

At first glance, they are the same type, both using a gate-like mechanism to control fluids. In fact, there are significant differences in their internal structure, performance under different conditions, and long-term maintenance requirements.

In this guide, we’ll explore the real differences between knife gate valves and gate valves, their ideal applications, and how to choose the right one for your specific needs.

PS: TOT valve is committed to providing excellent products and services to help you build high-quality solutions for fluid control systems. You are welcome to advisory our product catalog for more product information through enquiry@okvalveservice.com. You can also visit our okvalveservice.com site to get more resources about high-quality valves and their applications.

Table of Contents

ToggleBasic Definitions

Gate Valve: A gate valve is a linear-motion valve used to start or stop fluid flow. It operates by lifting a rectangular or wedge-shaped gate (disc) out of the path of the fluid. It’s most effective in fully open or fully closed positions and is typically used with clean media like water, oil, and gas.

Knife Gate Valve: A knife gate valve is a specialized version designed to handle thick fluids, slurries, and media with suspended solids. It features a sharp-edged blade that can cut through viscous or abrasive media. Originally developed for the pulp and paper industry, it’s now widely used in mining, wastewater, and chemical processing.

How They Work?

Both valves use a linear motion to move the gate up and down to control flow. However, they differ in how they handle media:

Gate Valve: Uses a wedge-shaped gate to create a tight seal against metal or elastomeric seats. Designed for clean flow with minimal particles.

Knife Gate Valve: Features a thinner, sharpened blade that slices through thick or solid-laden media, often sealing against soft seats to ensure full shutoff.

Design Differences

| Feature | Gate Valve | Knife Gate Valve |

|---|---|---|

| Gate Type | Solid wedge or flexible gate | Thin, sharpened blade |

| Body Design | Thicker, taller body | Compact, with wide port opening |

| Sealing Mechanism | Metal-to-metal or resilient seat | Soft seat or metal seat with packing |

| Pressure Rating | Suitable for high-pressure systems | Typically used in low to moderate pressure |

| Port Shape | Usually round | Often rectangular (square port) |

| Debris Tolerance | Low | High |

Materials & Pressure Ratings

Gate Valves: Commonly made from cast iron, carbon steel, stainless steel, or bronze. Available in pressure classes from Class 150 up to Class 1500 and beyond.

Knife Gate Valves: Often fabricated from stainless steel, ductile iron, or alloy materials, with pressure ratings up to Class 300. Their compact body makes them suitable for low-pressure, space-constrained systems.

PS: TOT Valve can provide you with stainless steel gate valves, ceramic gate valves, stainless steel knife gate valves and ceramic knife gate valves in various sizes and types. Each valve undergoes a strict quality control process before leaving the factory, and is packed and shipped to you only after 100% of the valves are qualified. Ensure stable and long-term operation in your fluid control system.

Advantages & Disadvantages

Knife Gate Valve – Pros & Cons

Advantages:

Excellent for slurry, pulp, wastewater, and solids-heavy fluids

Compact and lightweight

Low cost in large sizes

Easy to actuate

Disadvantages:

Not suitable for high-pressure or clean, compressible gases

Not bubble-tight in many cases

Limited in bidirectional sealing (TOT Valve can customize a bidirectional knife gate valve for you)

Gate Valve – Pros & Cons

Advantages:

Good for high-pressure, high-temperature applications

Reliable metal-to-metal sealing

Durable for clean media

Disadvantages:

Poor handling of solids or thick media

Larger and heavier body

More expensive in larger diameters

Use Cases & Industry Applications

| Application Area | Recommended Valve |

|---|---|

| Wastewater Treatment | Knife Gate Valve |

| Slurry or Mining Sludge | Knife Gate Valve |

| Pulp & Paper Industry | Knife Gate Valve |

| Potable Water Systems | Gate Valve |

| Oil & Gas Pipelines | Gate Valve |

| Steam or High Temp Flow | Gate Valve |

Knife gate valves shine in abrasive and slurry-heavy environments, while gate valves are ideal for high-pressure, clean-flow systems that require tight shutoff.

How to Choose Between the Two?

To choose the right knife gate valve or gate valve for your fluid control system, TOT Valve summarizes the following considerations and hopes to help you.

Consider Your Media Type

Knife Gate Valve: Best suited for slurry, pulp, sewage, or any fluid with suspended solids. The sharp gate cuts through thick or fibrous media without clogging.

Gate Valve: Ideal for clean, non-abrasive fluids like water, oil, or steam. It’s not designed to handle solids or viscous materials.

Assess Your Operating Pressure

Knife Gate Valve: Performs well in low-pressure applications, typically up to 10 bar (145 psi).

Gate Valve: Can handle higher pressures and temperatures, making it suitable for demanding industrial pipelines.

Evaluate Installation Constraints

Knife Gate Valve: Its slim body and compact footprint make it perfect for installations where space is limited.

Gate Valve: Requires more space for operation and installation due to its larger, heavier body.

Factor in Maintenance and Downtime

Knife Gate Valve: Fewer components, easier to disassemble, and generally faster to maintain.

Gate Valve: More complex internally; longer maintenance cycles and higher spare part costs.

Think About Flow Direction and Shutoff Needs

Knife Gate Valve: Often unidirectional—if you need flow control in both directions, choose a bidirectional model.

Gate Valve: Fully bidirectional by default, with a tight shutoff even under high pressure.

Budget Considerations

Knife Gate Valve: Typically more affordable both in upfront cost and lifecycle maintenance.

Gate Valve: Higher cost but also offers long-term reliability in demanding applications.

PS:Go with a knife gate valve when handling slurry or solids and minimizing cost and space is your priority. Choose a gate valve when you need dependable sealing under pressure, and the media is clean and free of particulates.

Conclusion

In the battle of knife gate valve vs gate valve, the winner depends entirely on your application. Knife gate valves excel in handling tough, solid-laden media in low-pressure environments, while gate valves shine in clean, high-pressure applications requiring durable shutoff. Understanding your system’s needs and operating conditions will guide you to the right choice.

PS: If you’re looking for expert advice on valve selection or need custom industrial valve solutions, don’t hesitate to contact us. TOT Valve As a professional industrial valve manufacturer and supplier, to help you optimize your flow control systems for maximum efficiency and reliability.

FAQ

What is a knife gate valve?

Knife gate valves are designed to handle media containing solid particles such as slurries, wastewater and pulp. It features a sharp-edged blade that can cut through thick, viscous, or abrasive flow and provides effective isolation in challenging process conditions.

What is a gate valve?

A gate valve is a linear-motion valve used to start or stop flow in a pipeline. It typically uses a solid wedge or parallel disc to block the flow and is best suited for clean fluids such as water, oil, and gas.

What’s the main difference between a knife gate valve and a gate valve?

The key differences include:

Design: Knife gate valves have a sharpened blade; gate valves use a wedge or slab-type gate.

Media Suitability: Knife gate valves handle thick, solid-laden media; gate valves are ideal for clean, low-viscosity fluids.

Sealing: Gate valves generally offer better bi-directional sealing.

Installation Space: Knife gate valves are more compact and suitable for tight installations.

When should use a knife gate valve?

Choose a knife gate valve if your system handles:

Slurry or sludge

Wastewater with solids

Pulp and paper stock

Abrasive or fibrous materials

It’s ideal for industries like mining, pulp & paper, wastewater treatment, and chemical processing.

What applications are best suited for gate valves?

Gate valves are recommended for:

Clean water supply systems

Oil and gas pipelines

Steam and thermal applications

Power plants and refineries

They are suitable for high-pressure and high-temperature systems where tight shut-off is required.

Can knife gate valves and gate valves be used interchangeably?

No. Despite similar names, they are not interchangeable. Knife gate valves are designed for slurries and solids, while gate valves are built for clean flow. Using the wrong valve type can lead to clogging, leakage, or valve failure.

Which valve is easier to maintain?

Knife gate valves typically require less maintenance in slurry or solid-handling applications due to their simple, open-body design. However, actual maintenance requirements depend on the installation and operating conditions.

What’s the cost difference between knife gate and gate valves?

Knife gate valves tend to be more cost-effective in larger sizes and in applications involving solids or slurry. Gate valves are often more expensive, especially in high-pressure or specialty material configurations.

How do choose the right valve for application?

- Media type: Use knife gate valves for slurry and solids; gate valves for clean fluids.

- Pressure rating: Gate valves for high-pressure systems.

- Space constraints: Knife gate valves offer a more compact design.

- Sealing requirement: Gate valves offer tighter shut-off, especially with metal seats.

- Maintenance access: Choose a design that aligns with your plant’s service capabilities.