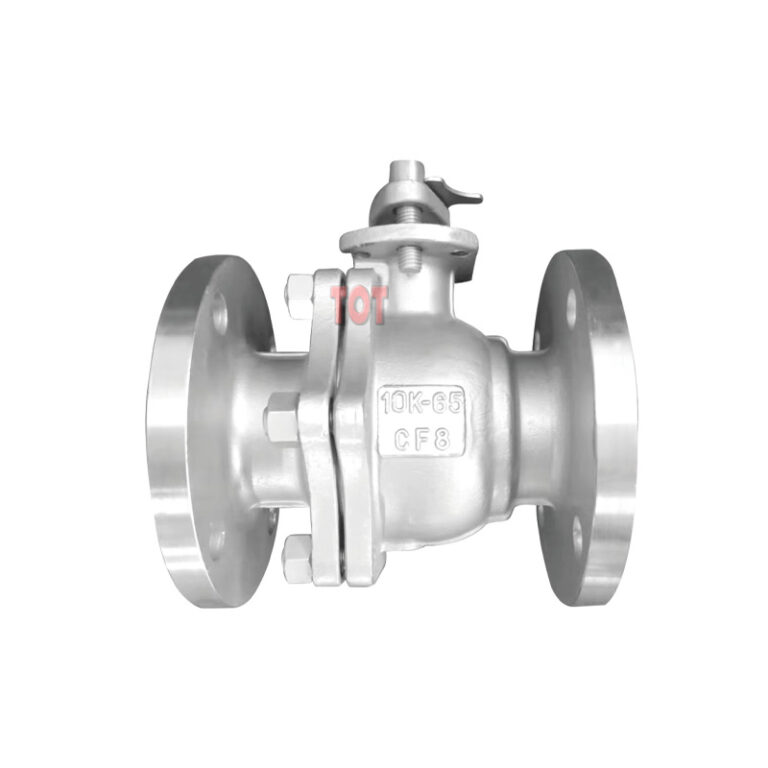

Industrial Ball Valves Manufacturer

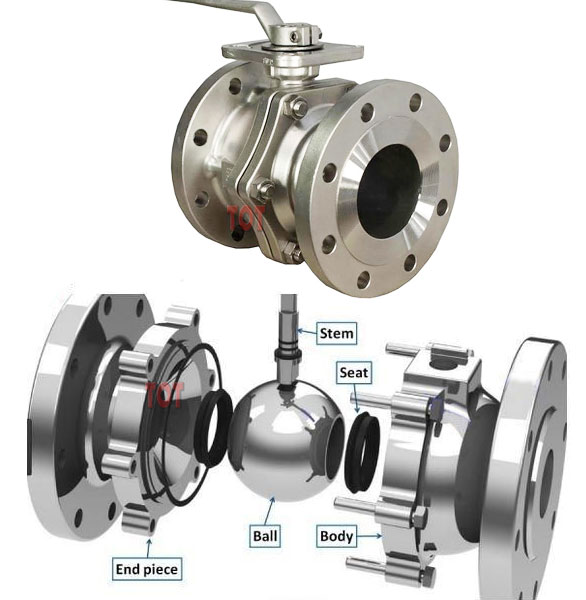

What is a ball valve? A ball valve is a quarter-turn shutoff valve that uses a hollow, pivoting ball to control flow. When you rotate the handle 90°, the ball opens or blocks the media path entirely—allowing fast and full isolation in one simple motion.

Unlike some valves used for throttling or flow control, ball valves are ideal for on/off control—especially in applications that require tight shutoff under high pressure or corrosive conditions.

When your system demands a fast, leak-proof shutoff solution, ball valves offer unmatched performance. As an industrial buyer, you need valves that combine operational simplicity with long-term durability—backed by a supplier who understands your industry. That’s where we come in.

At TOT Valve, we manufacture and supply industrial-grade ball valves built for precision control, dependable sealing, and reliable service life across harsh environments. Whether you operate in oil & gas, chemical processing, water treatment, or energy, our ball valves are designed to meet your specific operational and safety requirements.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Why Choose Ball Valves?

You might be wondering: “Why ball valves over other industrial valves?” The following are some factors we have summarized based on experience for your reference:

▸ Quick and Simple Operation

Open or close the valve with just a 90° turn—fast response time means better system control and less downtime.

▸ Excellent Sealing Performance

The ball presses firmly against the seat, creating a reliable seal. Ideal for gas, liquid, and chemical service requiring zero leakage.

▸ Low Pressure Drop

Ball valves offer unobstructed flow in the fully open position. You get more throughput, with minimal energy loss.

▸ Durable and Long-Lasting

With fewer moving parts and a compact design, ball valves last longer under pressure—literally. Our stainless steel and ceramic-seated designs offer superior wear and corrosion resistance.

▸ Versatile Installation

From threaded to flanged and welded ends, ball valves integrate easily into new builds or retrofits. We offer multiple connection types to suit your setup.

Applications of Ball Valves

Ball valves are highly adaptable and can serve in various industries where flow isolation is critical:

Oil & Gas Transmission

- Petrochemical Processing

- Water Treatment Plants

- HVAC and Power Systems

- Food & Beverage Pipelines

- General Industrial Use

Types of Ball Valves We Offer

Ball valves are an important part of most industrial liquid and gas control systems. There are a variety of ball valves on the market that can meet your different industrial needs such as reducing downtime or improving the overall performance of the system. Each ball valve has its own unique functions and advantages. Here is a summary of the different types of ball valves that we hope will help you choose the right ball valve.

By Valve Construction

Floating Ball Valves

Most common design. The ball “floats” between two soft seats and seals with upstream pressure. Great for low- to medium-pressure systems.

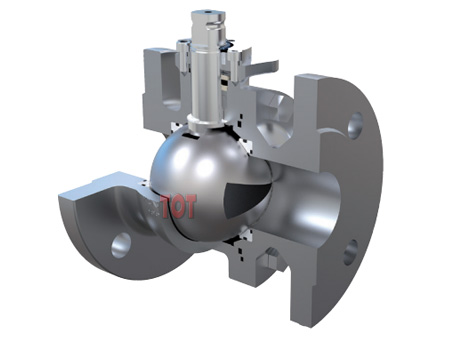

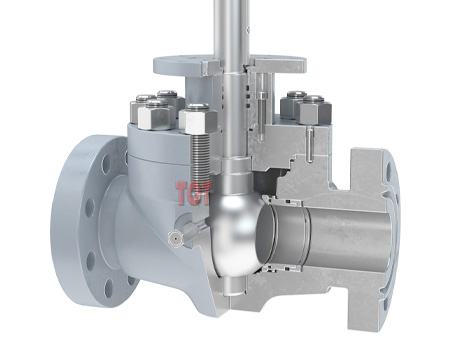

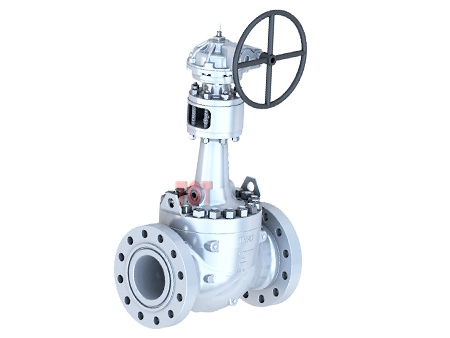

Trunnion Mounted Ball Valves

For high-pressure environments. The ball is anchored to minimize torque and seal wear. Widely used in oil, gas, and critical service applications.

By Flow Design

V-Port Ball Valves

Designed for applications requiring controlled flow rates. The “V” shape improves throttling performance.

Full Port Ball Valves

The bore matches the inner pipe diameter—no restriction, minimal pressure drop.

Reduced Port Ball Valves

Smaller bore reduces weight and cost, suitable for compact systems with moderate flow needs.

By Valve Construction

One-Piece Ball Valve

Economical, compact, and low maintenance. Best for simple shut-off tasks where cleaning isn’t needed.

Two-Piece Ball Valve

The body splits into two parts for better internal access. A great balance between performance and serviceability.

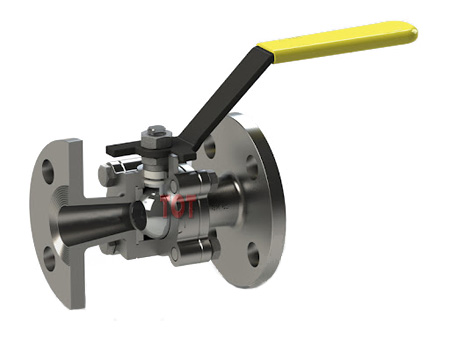

Three-Piece Ball Valve

Preferred for maintenance-heavy systems. You can remove the center body for cleaning or part replacement—no need to detach from the pipeline.

By Ball Support Mechanism

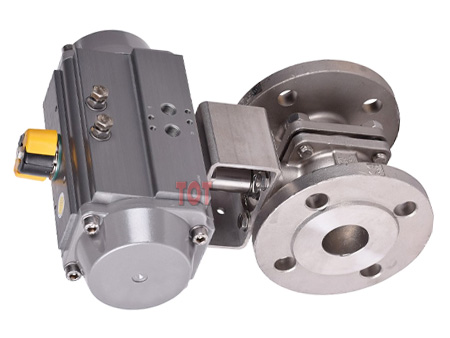

Top Entry Ball Valve

Easy inline maintenance. Access internals from the top—ideal for systems where downtime must be minimized.

Split Body Ball Valve

Bolted body design allows access to internal components for repair or inspection.

Rising Stem Ball Valve

The stem provides a visual indicator of open/closed status—ideal for high-safety environments.

* We are not just providing simple quotes but experts in selection, calculation, and drawing.

Ball Valves Data Sheet

We offer ball valves in a wide variety of materials tailored to your media, temperature, and pressure needs:

| Material | Best For | Features |

| 316 Stainless Steel | Corrosive chemicals, marine, food-grade | High resistance to rust, acids |

| Carbon Steel | Oil & gas, industrial | High strength, cost-effective |

| Brass | HVAC, water systems | Moderate corrosion resistance |

| Ceramic | Abrasive or high-velocity media | Extreme wear and corrosion resistance |

If you're unsure which material suits your line conditions, our engineering team will guide you through the selection.

Before choosing a ball valve, consider these technical factors:

| Parameter | Options / Ranges |

| Size Range | 1/2 inch to 24 inches |

| Pressure Rating | 150 LB to 600 LB |

| Temperature Rating | Up to 200°C (material dependent) |

| Connection Types | Flanged, Threaded, Welded |

| End Configurations | Two-way, three-way, multi-port |

| Standards Compliance | API 6D, ISO 5211, ASME B16.34, CE |

Choosing the right seat material is crucial for sealing performance:

| Seat Material | Application |

| PTFE (Teflon) | General-purpose, chemical resistant, up to 200°C |

| PEEK | High pressure, high temperature, excellent wear |

| Metal Seats | Abrasive media or steam |

| Graphite | Extreme temperatures and fire-safe designs |

| Ceramic | Abrasive or high-velocity media. Extreme wear and corrosion resistance |

We’ll recommend the best seat type based on your pressure, media, and temperature requirements.

FAQ

Ball valves are not ideal for throttling. Using them partially open can wear seats and affect flow control. For throttling, consider V-port or

With proper material selection, ball valves require minimal maintenance. For three-piece and top-entry designs, periodic seat replacement ensures long life.

Yes. We offer fire-safe and API 6D certified options upon request.