Stainless Steel Ball Valve Manufacturers

A stainless steel ball valve is a valve that uses a spherical ball with a hole (or port) in the center to control the flow of fluid or gas in a pipe. It is widely used in industrial applications to regulate or cut off the flow in a system.

When you open the Ball valve, the hole is aligned parallel to the pipe, allowing the fluid or gas to flow. When the valve is closed, the ball rotates to block the hole, stopping the flow.

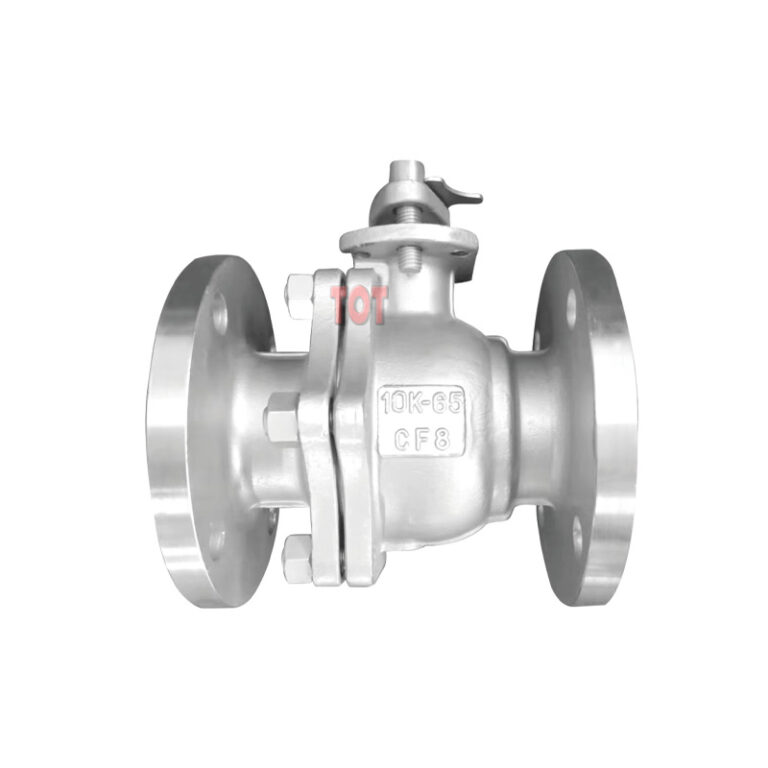

Our valve bodies are made of high-quality stainless steel, which has better corrosion resistance and durability than other materials such as carbon steel and cast steel. It can ensure its service life even if you use it in harsh environments.

To ensure the efficiency, safety and durability of industrial systems, TOT Valve focuses on manufacturing high-quality 316 stainless steel ball valves, 304 stainless steel ball valves, and providing customized Ball valve solutions based on your specific needs.

Whether you are upgrading an existing system or starting a new project, our extensive range of stainless steel ball valves can meet your needs for excellent performance and long life.

It is recommended that you do not settle for second-best products. Contact TOT Valve today to explore our full line of stainless steel ball valves, including stainless steel flanged ball valves, V-port ball valves, floating ball valves, trunnion ball valves, and more. Let us help you find the perfect valve solution for your industrial needs.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

All You Need to Know About SS Ball Valve

We know that investing in high-quality stainless steel ball valves is a long-term commitment, and at TOT Valve, we are dedicated to providing you with solutions that enhance your system’s reliability. Our products are built to handle even the most demanding environments, ensuring your operations run smoothly without costly interruptions.

Key Features of Our Stainless Steel Ball Valves

TOT Valve offers a diverse selection of ball valves, ensuring you get the perfect fit for your system. Here’s what makes our valves stand out:

Blowout-Proof Stem Design: Enhance safety with valves that prevent stem blowouts, even under high-pressure conditions.

Full Range: Each type of our valve has a variety of sizes for you to choose from, from compact to larger industrial sizes to meet your specific needs.

- V-Port Ball Valve: Achieve precise flow control with our V-Port Ball Valves, which allow you to fine-tune flow rates in applications that require throttling or precise modulation.

- Segment Ball Valve: Also known as V-notch ball valve, is a type of regulating ball valve. Its ball is a partial spherical surface with a V-shaped notch (V-notch) on the ball. With a fixed valve seat, more precise flow control can be achieved.

- SS Flange Ball Valve: We offer SS flange ball valves that provide a secure, leak-proof connection for high-pressure systems.

- Floating Ball Valve: The ball is not fixed and “floats” between two seats. This design is typically used for low- to medium-pressure applications.

- Trunnion Ball Valve: The ball is fixed and mounted at two points, making it suitable for high-pressure systems and larger pipe sizes.

Customization: Need a unique size or configuration? We offer custom designs, including V-Port ball valves and SS flange ball valves, to suit your specific needs.

Competitive Pricing: As direct manufacturers, we provide top-quality valves at factory prices, helping you reduce costs without compromising on performance.

Wide Range of Materials: Choose from 316 stainless steel for high corrosion resistance or 304 stainless steel for general-purpose applications. For even higher performance, our CF8M ball valve offers the durability required in aggressive fluid environments.

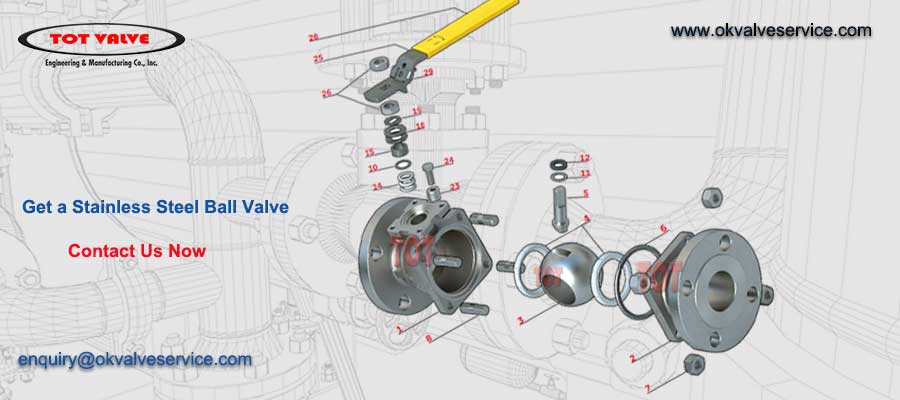

| NO. | Name | Stainless Steel | Cast Steel |

| 1 | Valve Body | ASTM A351 Gr CF8M | ASTM A216 Gr WCB |

| 2 | Valve Cover | ASTM A351 Gr CF8M | ASTM A216 Gr WCB |

| 3 | Ball | ASTM A351 Gr CF8M | |

| 4 | Seat | TFM 1600 | |

| 5 | Stem | ASTM A479 316 | |

| 6 | Seal | Spiral Wound Gasket (316/graphite) | |

| 7 | Body Nut | ASTM A194 Gr 8 | |

| 8 | Body Stud | ASTM A193B8 ASTM A193 B7 | |

| 9t | Antistatic Device | SS304 | |

| 10 | Packing Protection | PEEK | |

| 11 | Thrust Washer Protection | PEEK | |

| 12 | Thrust Washer | Tek-Fil | |

| 13 | Stem Bearing | 15% RPTFE | |

| 14 | Stem packing | RPTFE or Graphite | |

| 15 | Packing Gland | ASTM A167 Type 304 | |

| 16 | Packing Gland Ring | ASTM A351 Gr CF8M WCB ASTM A216 Gr | |

| 17 | Gland Bolt | SS304 | |

| 18 | Dish Washer | SS301 | |

| 19 | Locking Washer | SS304 | |

| 20 | Travel Limiter Bracket | ASTM A351 Gr CF8M | ASTM A216 Gr WCB |

| 21 | Limiting Bolt | SS304 | WC6 |

| 22 | Travel Limiter | SS304 or Galvanized Steel | |

| 23 | Travel Limiter Sleeve | ASTM A167 304 | |

| 24 | Travel Limiter Bolt | SS304 | |

| 25 | Handle | SS304 or Ductile Iron | |

| 26 | Locking Nut | ASTM A167 304 | |

| 27 | Handle Fixing Screw | Carbon Steel | |

| 28 | Handle Sleeve | Vinyl, Up to 2″ | |

| 29 | Locking Device | SS304 | |

| 30 | Circlip Ring | Nickel-plated Steel | |

| 31 | Handle Joint | SS304 or Ductile Iron | |

| 32 | Valve Stem Bolt | WC6 | |

| 33 | Handle Bolt | WC6 | |

Applications of Stainless Steel Ball Valves

Our stainless steel ball valves are engineered for a wide range of industries:

Chemical Processing: Safely handle corrosive liquids with 316 stainless steel ball valves designed for chemical resistance.

Oil and Gas: For high-pressure and hazardous environments, our CF8M ball valve provides a reliable, leak-proof solution.

Water Treatment: Achieve efficient flow control with 304 stainless steel ball valves, perfect for water treatment systems.

Food and Beverage: Maintain hygiene standards with valves that meet industry-specific regulations for clean processing.

Pharmaceuticals: Ensure contamination-free processes with our precision-engineered valves.

How to Choose the Right Stainless Steel Ball Valve?

Selecting the ideal stainless steel ball valve for your application can be challenging, but we’re here to help. Consider these key factors when making your choice:

Application Conditions: For highly corrosive environments, opt for a 316 stainless steel ball valve for superior resistance. For more general applications, a 304 stainless steel ball valve may be sufficient.

Flow Control Needs: If you need to control flow rates precisely, consider a V-Port Ball Valve.

End Connections: We offer a range of options, including SS flange ball valves, threaded, and welded connections for easy integration into your system.

* We are not just providing simple quotes but experts in selection, calculation, and drawing.

FAQ

A V-Port ball valve is designed with a V-shaped port on the ball, which allows for more precise control of fluid flow. This type of valve is ideal for throttling applications, where you need to regulate flow rates rather than just turning the flow on or off. It’s commonly used in systems requiring fine adjustments to fluid flow, such as in chemical processing or water treatment.

Floating ball valves have a ball that "floats" between two seats. These are typically used in low- to medium-pressure systems. The ball is free to move slightly to ensure a tight seal when closed.

Trunnion ball valves, on the other hand, have a fixed ball that is supported at two points. These valves are better suited for high-pressure applications and large pipe sizes, as they provide more stability and support to the ball.

Yes, stainless steel ball valves are ideal for high-temperature environments, especially those made from 316 stainless steel or 304. These materials can withstand temperatures ranging from -100°F to +1000°F (-73°C to +538°C), depending on the specific valve design and material grade.

SS flange ball valves are designed with flanged ends that allow them to be securely bolted to a pipeline. These are commonly used in high-pressure systems where a strong, leak-free connection is essential. They are particularly effective in applications where standard threaded or welded connections might not be suitable.

When selecting a stainless steel ball valve, consider factors such as:

Pressure: Ensure the valve can handle the required pressure ratings.

Temperature: Choose a valve material suitable for the temperature range in your system (e.g., 304 or 316 stainless steel for high temperatures).

Fluid Type: If you’re working with corrosive or abrasive fluids, select valves made from 316 stainless steel or CF8M for better corrosion resistance.

Size and Connection Type: Select the appropriate valve size and connection type (flanged, threaded, welded) based on your system requirements.

Flow Control: For precise flow control, consider a V-Port ball valve.

Yes, stainless steel ball valves can be easily automated using electric, pneumatic, or hydraulic actuators. This is particularly useful in systems where precise control and remote operation are necessary, such as in large industrial plants or automated production lines.