Check Valve Manufacturers

Ensure one-way flow, protect your equipment, and optimize system performance with TOT's precision-engineered check valves.

What is a check valve? A check valve—also known as a non-return valve or one-way valve—is your system’s silent guardian. It allows fluid (liquid or gas) to flow in only one direction, automatically preventing reverse flow that could damage your pumps, disrupt your process, or contaminate clean media. Whether you’re managing a high-pressure pipeline or a delicate dosing system, the check valve stands between smooth operation and costly failures.

At TOT, we understand how crucial that role is. That’s why we design and manufacture check valves that are tough, dependable, and built to last—even in the harshest industrial environments.

Ready to Secure Your Flow? Contact us today to request a quote.

Your pipeline system deserves reliable protection—let’s build it together.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Advantages of TOT Check Valves

When you choose a TOT check valve, you gain more than just a component—you gain:

▸ Self-Actuated Reliability – No external power or actuation required

▸ Broad Material Options – From stainless steel to ceramics and elastomers

▸ Low Maintenance – Fewer moving parts, longer service intervals

▸ Wide Compatibility – Designed for water, oil, gas, chemicals, slurry, and steam

▸ Custom Solutions – Engineered to fit your exact pressure, temperature, and installation specs

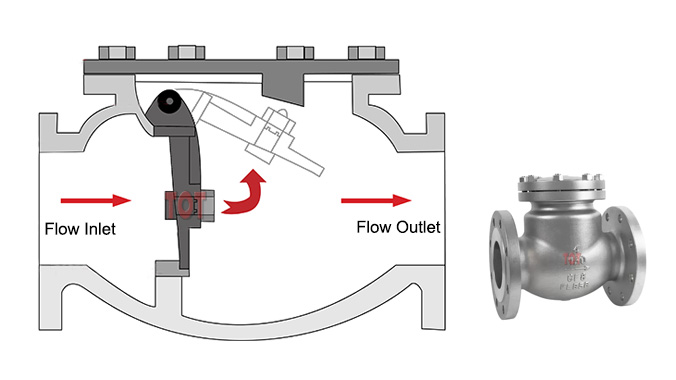

How Does a Check Valve Work?

You don’t need to control it. You don’t even need to power it. A check valve works entirely on its own.

When fluid flows in the correct direction, the internal mechanism—typically a disc, ball, or diaphragm—lifts away from the seat, allowing flow to pass through freely. But if the flow reverses? The valve automatically shuts, blocking backflow and protecting your system. Some models use springs to speed up closure, and the “cracking pressure” ensures your system opens only when it’s supposed to.

This passive but essential operation helps you maintain consistent pressure, reduce wear on pumps, and avoid pressure surges known as water hammer.

Types of Check Valves

Check valves are essential components in various piping systems. They are designed to allow fluid to flow in one direction while preventing backflow. There are many types of check valves to suit your different media, flow characteristics, pressure conditions and installation directions. The following are the common check valve types and a brief overview that we provide, hoping to help you choose the right check valve.

Swing Check Valve

Ideal for low-pressure pipelines and clean liquids. The disc swings open with flow and seals shut when it stops—simple, effective, and low maintenance. Best for water, HVAC, non-pulsating flow pipelines systems.

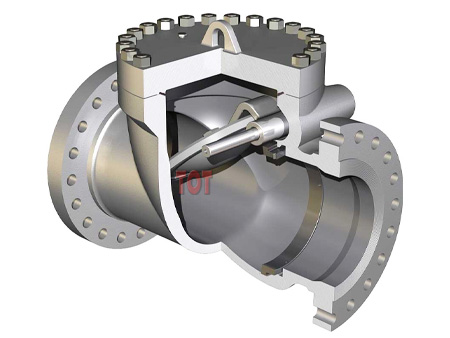

Lift Check Valve

The disc lifts vertically off the seat when fluid flows, then drops back to seal under gravity or reverse pressure. With excellent sealing under high-pressure conditions, this type is great for precise systems, such as steam, gas and high-pressure liquid.

Ball Check Valve

Using a spherical ball as the closing element, this valve handles media with suspended solids like a champ. It’s self-cleaning and performs well in horizontal installations. Best for wastewater, slurry, and abrasive or viscous fluids.

Wafer Check Valves

Wafer check valves called butterfly check valves—are ultra-compact, lightweight, and designed to fit between flanges. They use a dual-plate (or swing disc) mechanism that opens when fluid flows forward and snaps shut when flow reverses.

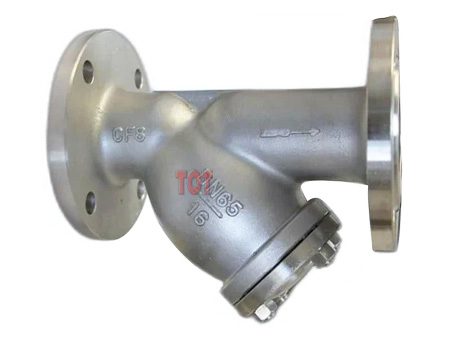

Y Check Valve

Named for its angled “Y” shape, this valve design allows smoother, straighter flow paths with less resistance. The internal disc or poppet rests diagonally, which helps reduce pressure drop and makes the valve easier to clean and maintain.

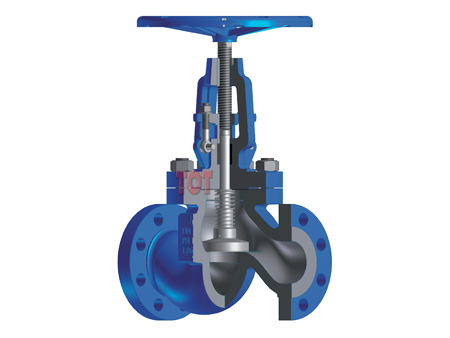

Stop Check Valve

A stop check valve is a hybrid check valve because it has an actuator or manual overrun device to control the flow of the medium. This valve can be used to work in both check and on-off valve modes. It is commonly found in power plants, steam generators, or safety systems.

Applications of Check Valves

TOT check valves are at work in a wide variety of industries:

- Water & Wastewater Treatment – Protect clean water lines and prevent contamination

- Oil & Gas Pipelines – Safeguard against backflow in critical flowlines

- Power Plants & Boilers – Maintain flow direction in high-temperature environments

- Chemical Processing – Avoid mixing of reactive or hazardous substances

- HVAC & Plumbing – Ensure stable pressure and prevent reverse flow

- Mining & Slurry Transport – Handle abrasive media without clogging

Wherever one-way flow is critical, check valves are essential.

Check Valve vs. Globe Valve – Know the Difference

| Feature | Check Valve | Globe Valve |

| Flow Control | One-way flow, prevents backflow | Manual or actuator control to regulate flow |

| Operation | Automatic | Manual or powered |

| Flow Direction | Unidirectional | Bidirectional |

| Pressure Drop | Low | High |

| Use Case | Protect pumps, stop reverse flow | Throttle or shut off flow |

| Maintenance | Minimal | Moderate to high |

*Need backflow prevention? Go with a check valve. Need to regulate flow rates? A globe valve is the better option.

FAQ

Swing check valves use a pivoting disc, while lift check valves use a vertically moving disc. Swing types are better for low pressure, while lift types perform better under high-pressure conditions.

Yes—some models like lift or ball check valves can be installed vertically, as long as flow direction is correct. Always check the product spec before installation.

Choose slow-closing or spring-assisted models, or pair the valve with a dampener system. We can help you choose the best solution.

At TOT, we don’t just manufacture valves—we deliver confidence. With years of experience in industrial valve production and a focus on international standards, we serve clients across oil & gas, water treatment, power generation, and more.

You benefit from:

✔ Full customization options

✔ Competitive pricing for bulk orders

✔ Strict QC processes and pressure testing

✔ Fast lead times and reliable global shipping

✔ Technical support from selection to installation

When the flow must go right—choose TOT check valves.

Not all check valves are created equal. To get the best results, consider:

- Media Type – Is it clean water or abrasive slurry? Corrosive chemicals or clean gas?

- Flow & Pressure Conditions – What’s your minimum operating pressure? Do you need a fast-closing valve?

- Mounting Orientation – Horizontal or vertical installation can affect performance

- Size & End Connections – Flanged, threaded, or welded? Ensure compatibility.

- Maintenance Access – Some valves allow inline servicing, while others must be removed

Still unsure? Our engineering team is ready to help you specify the right valve for your system.