Rubber Expansion Joints Manufacturers

Rubber expansion joints are flexible connectors for piping systems to absorb displacement, vibration and thermal expansion. They are designed to compensate for pipe misalignment, thermal expansion, pressure thrust, and reduce noise and vibration. It consists of a rubber expansion joint and a flange. The connecting flange we equip meets the DIN PN10/16 standard, which you can easily integrate into the existing piping system.

The procurement standards for raw materials at TOT are very strict. We use high-quality EPDM, neoprene, fluororubber or PTFE as the soft connection part of the rubber expansion joint, and both ends are equipped with weather-resistant galvanized steel or stainless steel flanges. Whether you are using it in drinking water, heating, ventilation, air conditioning and industrial systems, its high flexibility and extended service life are guaranteed.

All of our rubber expansion joints undergo rigorous testing to ensure they meet ANSI standards and perform reliably in your system.

Contact us now, let us help you optimize your pipeline efficiency and reduce operational downtime today.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Why Choose Rubber Expansion Joints?

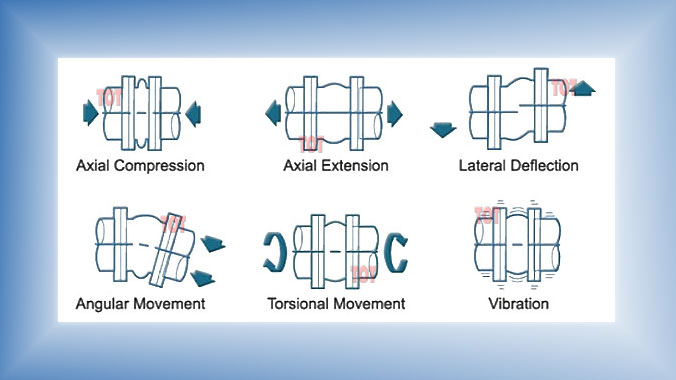

Rubber expansion joints are the ideal choice for a variety of applications, providing both flexibility and durability in your piping systems. They are specifically designed to absorb and compensate for movements, pressure thrust, noise, and vibrations—issues often encountered in industrial and HVAC systems.

Key Benefits:

Vibration and Noise Reduction: Rubber expansion joints are excellent for isolating noise and vibrations from mechanical equipment. This is particularly useful in HVAC systems and industrial applications where machinery generates unwanted sound or movement.

Pipe Movement Absorption: They are designed to handle thermal expansion, equipment settling, and other movements that occur in pipes due to fluctuating temperatures and mechanical forces.

Increased System Longevity: By absorbing these dynamic forces, rubber expansion joints prevent strain on other parts of the system, thus extending the lifespan of your piping infrastructure.

Applications You Can Trust

HVAC Systems: In HVAC systems, rubber expansion joints are used to absorb thermal expansion and to isolate noise and vibration between pumps, compressors, and other equipment. These joints ensure that mechanical vibrations are not transmitted through the system, preventing damage and improving system efficiency.

Industrial and Pump Systems: Rubber expansion joints effectively isolate pumps and other industrial equipment from the piping system. This not only reduces noise but also prevents the transmission of vibrations that can lead to equipment damage over time.

Pipeline Flexibility: Rubber expansion joints offer flexibility when dealing with pipe movements, whether it’s axial, transverse, or angular. They are especially beneficial in systems where pipes expand or contract due to temperature changes.

Types of Rubber Expansion Joints

At TOT Valve, there are various styles and configurations of rubber expansion joints available to suit different applications.

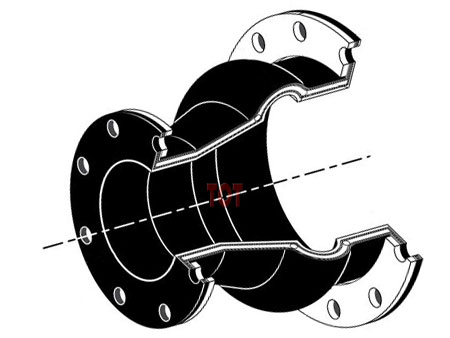

Single Sphere Expansion Joints

Ideal for absorbing small pipe movements, these joints are perfect for noise and vibration isolation in smaller applications, especially in HVAC systems.

Double Sphere Expansion Joints

For greater movement capabilities, the double sphere design offers superior flexibility and vibration isolation. These are commonly used in larger systems where more pipe movement is expected.

Reducer Expansion Joint

These are best used in applications with medium to large particulate matter. Their design allows for easy installation and efficient filtration without taking up excessive space.

Spool-Type Expansion Joint

With an arched structure to absorb large pipe displacements, they are designed for high pressure, high temperature and abrasive environments.

We design, engineer and produce your tailor-made expansion joints.

Why TOT Rubber Expansion Joints Outperform Other Options

When it comes to flexibility and durability, rubber expansion joints hold a significant advantage over their metal counterparts. Unlike metal bellows, rubber joints are capable of handling vibration and noise much more effectively. Their spherical design helps distribute internal pressures evenly, reducing turbulence and preventing any unwanted growth due to pressure thrust forces.

Materials You Can Rely On:

The elastomers used in rubber expansion joints vary, with options such as EPDM, Neoprene, Viton, and PTFE available. The choice of material depends on the specific needs of your piping system—whether it’s exposure to chemicals, high temperatures, or abrasive media. For instance:

EPDM is ideal for hot air and water applications.

Neoprene is commonly used for general-purpose use.

Viton and PTFE are perfect for chemical handling, offering superior resistance to acids and harsh environments.

Rubber Expansion Joints Save You Money

They help save you money in the long run. By reducing strain on your piping system, they prevent costly repairs and replacements. Furthermore, they eliminate the need for more expensive mechanical vibration isolation solutions, offering an effective yet affordable alternative.

Customizable for Your Needs

No two piping systems are the same, which is why we offer customizable rubber expansion joints to meet your exact specifications. We provide various flange options, face-to-face dimension choices, and even custom drilling to ensure that your expansion joint fits seamlessly into your existing system.

Accessories: For additional reliability, we also offer retaining rings, control units, and safety shields to provide further protection to your rubber expansion joints, ensuring they perform optimally for years.

Installation and Maintenance Tips

When installing rubber expansion joints, make sure to evenly distribute the bolting forces to achieve the best clamping force. It’s also important to use proper sealing materials like ring gaskets or full-face gaskets when installing against raised-face flanges to prevent leaks.

Routine inspection and maintenance are essential to ensure the continued performance of your rubber expansion joints. Check for any signs of wear or damage, especially in high-stress areas, and replace the joints as needed to keep your system functioning smoothly.