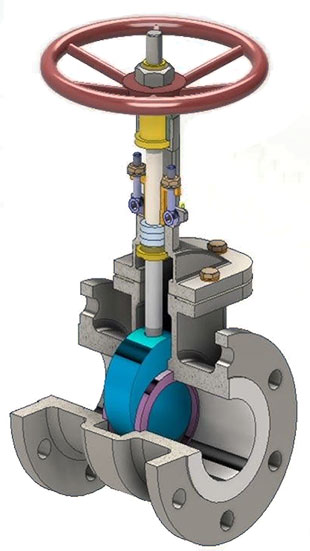

What is a Gate Valve?

A gate valve is a linear motion valve that uses a flat or wedge-shaped gate to start or stop the flow of fluid. It’s not about throttling – it’s about full bore or zero flow. You choose a gate valve when your process demands minimal pressure drop, tight shut-off, and reliability over time.

What does this mean for you? · Efficiency · Less Maintenance · Fewer Shutdowns · More Control

When you’re sourcing industrial valves for critical flow control, you need more than just a product – you need certainty. As a professional in your industry, you understand how crucial reliability, compatibility, and performance are to your operations. That’s where TOT Valve comes in. We are your trusted Chinese manufacturer specializing in API, ASTM, ANSI, JIS, DIN, GOST, and CE standard gate valves engineered for consistent performance under the toughest conditions.

TOT Gate Valves aren’t just designed. They’re built around you – your industry, your specifications, and your operational challenges. Whether you’re dealing with high-pressure pipelines, abrasive media, corrosive environments, or extreme temperatures, you’ll find a solution in our comprehensive gate valve lineup.

Gate Valve Collection

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

What Can TOT Gate Valves Solve for You?

Unplanned Downtime: Our valves are built to last. With robust construction and premium materials, you reduce the risk of failure that halts operations.

Leakage Issues: Precision-machined sealing surfaces, along with flexible and solid wedge options, ensure tight shut-off you can count on.

Media Compatibility: Whether it’s water, oil, gas, steam, or slurry – we offer the right internal components and coating solutions.

Harsh Environments: High temp? Corrosive chemicals? Abrasive solids? We engineer for resilience.

Standard Compliance: Avoid costly rework or import rejections – our valves meet international standards including API 600, API 6D, DIN, and JIS.

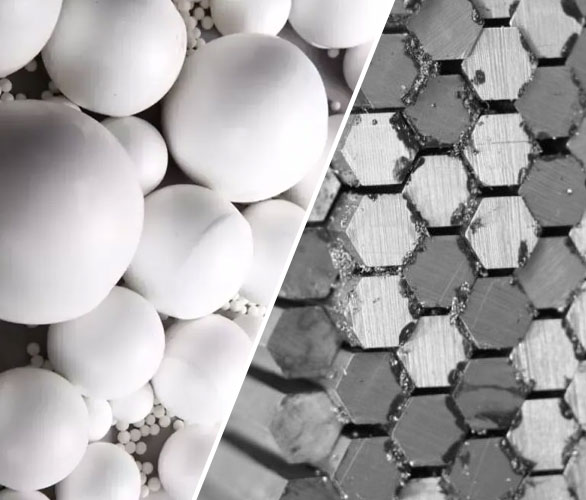

Materials You Can Rely On

TOT Valve offers a diverse range of body, wedge, and stem materials including:

Carbon Steel (WCB, LCB)

Stainless Steel (CF8, CF8M, CF3, CF3M)

Alloy Steel (WC6, WC9, C5, C12)

Ceramic-Lined for High Abrasion

Every material is traceable

Every product is tested, No compromise.

Your Complete Gate Valve Portfolio – Engineered to Fit

You can count on us for a wide range of gate valve designs, materials, and sizes tailored to your industry’s exact demands.

Rising Stem Gate Valves

Easy visual position indication, common in oil & gas, chemical, and water systems

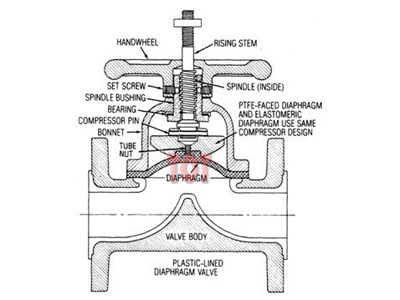

Non-Rising Stem Gate Valves

Ideal for space-limited installations, often used in fire protection and underground networks

Flexible Wedge Gate Valves

Handles pipe stress and thermal fluctuations well,welf-aligning for consistent sealing

Solid Wedge Gate Valves

Best for high-pressure and high-temp environments, durable, no flexing under stress

Ceramic Lined Gate Valves

Outstanding resistance to abrasion and corrosion, excellent for mining, slurry transport, and power plants

Stainless Steel Gate Valves

Excellent corrosion resistance, widely used in food, pharma, and chemical industries

Cast Steel Gate Valves (API 600)

Designed per API 600 for high-pressure applications, widely used in oil & gas, refinery, and petrochemical industries

Custom Gate Valves

Need something unique? We customize trim, materials, actuation, and more.

Advantages of TOT Gate Valve

TOT Valve is more than just a gate valve manufacturer, we are your trusted partner. With years of casting and machining manufacturing experience, and strict quality control processes such as material traceability, pressure testing, NDT, you can get the performance and reliability you need.

Variety Sizes &Pressure Ratings for You Choose

- Size Range: 1/2″ to 24″

- Pressure Ratings: Class 150 to Class 600 / PN10, PN16

- Connection Types: Flanged, Threaded, Butt Weld, Socket Weld

- End Standards: ASME, DIN, JIS, GOST

Operation Types that Work the Way You Do

- Manual Handwheel Operation

- Bevel Gear Operated for Large Sizes

- Electric Actuators for Remote Control

- Pneumatic Actuated for Speed and Automation

Industries That Count on TOT Gate Valves

- Oil & Gas (upstream to downstream)

- Refining & Petrochemicals

- Water Treatment & Distribution

- Power Generation

- Mining and Slurry Systems

- Chemical Processing

- Marine and Offshore Platforms

- HVAC & Firefighting

Quality, Customization, and a Team That Gets It

- TOT isn’t just about valves – we’re about delivering the exact product you need:

- Custom Materials & Coatings

- OEM Manufacturing

- Fast Prototyping & Small Batch Runs

- Global Shipping with Documentation Support

- Our engineers speak your language – whether it’s specs, drawings, or certifications.

Compare Gate Valves vs. Other Valve Types

| Valve Type | On/Off Control | Throttling | Flow Resistance | Application Fit |

| Gate Valve |  Best Best |  Not ideal Not ideal |  Low Low | Clean isolation |

| Globe Valve |  Good Good |  Excellent Excellent |  Higher Higher | Flow control |

| Ball Valve |  Excellent Excellent |  Limited Limited |  Very Low Very Low | Fast shut-off |

| Butterfly Valve |  Good Good |  Moderate Moderate |  Medium Medium | Compact systems |

Tip: Use gate valves where full open/full close is critical, and pressure drop needs to be minimal.

TOT Valve Manufacturing and Quality Control

At TOT Valve, our manufacturing process is carefully designed to ensure the production of the highest quality industrial valves.

Material Preparation: We use high-grade raw materials such as high-quality SS 304/SS 316L/SS316Ti stainless steel, brass and ceramics.

Valve Body Processing: We have our own foundry, where we cast the raw materials precisely.

Valve assembly: Assemble the valve body, valve stem, valve seat, seals and other parts. We generally use a combination of mechanical processing and manual assembly.

Valve Testing: TOT Valve has a strict quality inspection system and tests the assembled valves, including size, leak plugging, corrosion resistance, pressure resistance and other tests.

Cleaning and Surface treatment: Clean the assembled valves to remove surface impurities and stains, or perform surface treatments such as polishing, sandblasting, and spraying.

Packaging and Storage: Pack the valves, mark and record them, and store them in the designated warehouse.

By adhering to these meticulous manufacturing processes, TOT ensures that every industrial valve produced meets the highest standards of quality and performance. Our commitment to excellence in every step of production reflects our dedication to providing quality products that our customers can trust.