Ceramic Gate Valve Manufacturer in China

Ceramic gate valves are industrial valves designed for controlling fluids in highly abrasive or corrosive environments such as slurries and dry powders.

We use high-quality industrial ceramic materials to make linings (moving parts for opening or closing flow) and valve seats (gate sealing parts), such as aluminum oxide (Al₂O₃), zirconium oxide (ZrO₂) or silicon carbide (SiC).

Ceramic serves as a key internal seal and wear surface. When you’re dealing with highly abrasive slurries, corrosive powders, or high-solid content fluids, traditional metal gate valves just don’t cut it. That’s where a Ceramic Gate Valve comes in — a powerful solution engineered to thrive in the toughest industrial environments.

At TOT Valve, we specialize in the design and manufacture of high-performance ceramic gate valves, helping you reduce downtime, extend valve service life, and enhance long-term system reliability.

Ready to upgrade your system with high-performance ceramic gate valves? Reach out now for:

- ✔ Engineering consultation

- ✔ 2D/3D drawings

- ✔ Material recommendations

- ✔ Competitive factory pricing

Contact TOT Valve, your trusted ceramic gate valve manufacturer in China as your partner.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Why Choose a Ceramic Gate Valve?

Your operation demands more than just a valve that opens and closes. You need a solution that can:

- Withstand aggressive wear from solid particles

- Resist corrosive chemicals and media

- Deliver tight shutoff over thousands of cycles

- Operate with minimal maintenance over years

That’s exactly what a ceramic gate valve offers. Here’s why it’s the smart choice for demanding applications:

Exceptional Wear Resistance

The ceramic sealing surfaces, made from advanced materials like alumina (Al₂O₃), zirconia (ZrO₂), or silicon carbide (SiC), boast a hardness of up to HRA 88–92, far exceeding traditional stainless steel or hard-alloy overlays.

Superior Corrosion Resistance

Ceramic materials are chemically inert and immune to acid, alkali, and salt corrosion, making them ideal for chemical processing, desulfurization, or slurry handling.

Extended Service Life

Compared to metal gate valves, ceramic gate valves often last 3–5 times longer — significantly reducing your valve replacement costs.

Precision Shutoff

Thanks to the high machining accuracy of ceramic components, you benefit from tight shutoff, minimal leakage, and stable performance, even after prolonged use.

TOT Ceramic Gate Valve Solutions

TOT Valve offers a full range of ceramic gate valves tailored to high-wear and high-corrosion scenarios. We work closely with you to ensure the valve matches your process requirements.

- Sizes: DN50–DN600 (2″ to 24″)

- Pressure Ratings: PN10 / PN16 / Class 150

- Body Materials: WCB, Stainless Steel, Duplex Steel

- Sealing Surfaces: 95%–99% Alumina / Zirconia / Silicon Carbide

- Operation: Manual, Pneumatic, Electric, Hydraulic

- Connection: Flanged or Wafer

Ceramic Gate Valves Available Customizations

You don’t need to settle for off-the-shelf. TOT offers:

- ✔ Alternate ceramic grades for different pH or abrasion levels

- ✔ Special coatings or linings for the valve body

- ✔ Custom face-to-face dimensions

- ✔ Different actuator mounting interfaces

- ✔ Temperature- and pressure-specific designs

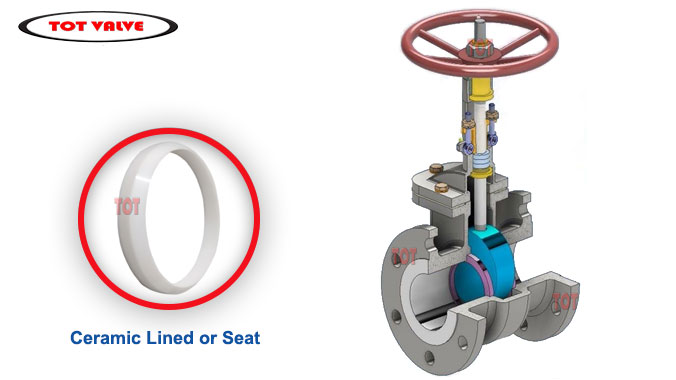

Structure Breakdown: How Ceramic Gate Valves Work

A typical TOT Ceramic Gate Valve includes the following core components:

- Valve Body (Carbon Steel / SS) – Provides pressure-bearing structure

- Ceramic Gate Plate – Precision machined for tight shutoff

- Ceramic Valve Seat – Replaceable insert, resisting wear and corrosion

- Stem & Packing – Ensures reliable operation and sealing

- Actuator (Optional) – Manual, pneumatic, or electric drive

Applications You Can Rely On

You’ll find ceramic gate valves indispensable across industries where media is highly abrasive or chemically aggressive.

- Power Plant Dry Ash Systems

- Alumina and Bauxite Slurry Transfer

- Mining Tailings & Concentrates

- Coal Chemical Processes

- Pneumatic Conveying of Dry Powder

- Desulfurization in FGD Systems

- Cement Industry Raw Materials Control

If your media causes premature failure of regular valves, switching to ceramic is the proven way to improve uptime and cut replacement frequency.

Where Ceramic Gate Valves Outperform Metal Valves

| Feature | Ceramic Gate Valve | Traditional Metal Gate Valve |

| Wear Resistance | ★★★★★ (HRA 88+) | ★★☆☆☆ |

| Corrosion Resistance | ★★★★★ | ★★★☆☆ |

| Service Life | 3–5x longer | Short lifespan in harsh media |

| Shutoff Performance | Excellent | Gradual decline with wear |

| Maintenance Frequency | Low | High |

| Lifecycle Cost | Lower long-term | Higher long-term |

FAQ

Yes. Our ceramic materials withstand up to 1000°C, but system design must ensure thermal expansion is managed.

TOT valves are proven to work in 30%–50% solid concentration without performance loss.

Absolutely. All ceramic sealing parts are modular and replaceable.

Our engineering ceramics are toughened, and structural design ensures mechanical protection.