Stainless Steel Gate Valves Manufacturers

A stainless steel gate valve is a stainless steel valve that uses a sliding gate mechanism to control the flow of fluid or gas in a pipeline. Unlike other types of valves, such as ball valves or globe valves, gate valves are primarily used to control flow on/off rather than regulating or throttling. When fully open, gate valves provide a straight, unobstructed flow path, minimizing pressure loss.

Stainless steel gate valves are made of high-quality stainless steel to ensure their excellent corrosion, heat and pressure resistance. At the same time, they ensure that the valves can withstand the harsh environment and maintain long-term performance in your system, such as oil and gas, chemical processing, water treatment and power plants.

We have gate valves in a variety of sizes (1/2” to 24” stainless steel gate valves), pressure ratings (Class 150 to Class 600 LB) and materials to meet your specific needs. Whether you need valves for high-pressure systems or corrosive substances, we can customize solutions for you.

As a reliable stainless steel gate valve manufacturer in China, we produce valves that meet international standards such as API, DIN, JIS and GOST. Our commitment to quality ensures that all valves are tested to guarantee their performance and reliability.

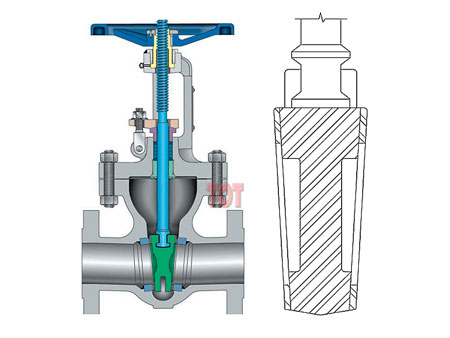

Key Components of a Stainless Steel Gate Valve

» Read More

Body: The main structure of the valve, typically made from stainless steel, is designed to withstand high pressure and temperature.

Gate: The sliding mechanism that moves up and down to open or close the valve. It is typically wedge-shaped or parallel depending on the design.

Stem: A component that connects the handwheel (or actuator) to the gate, transmitting the force needed to operate the valve.

Seat: The area where the gate seals against the valve body to stop fluid flow.

Bonnet: The upper part of the valve that houses the stem and packing to prevent leakage.

» Read Less

Contact us now, let us help you optimize your pipeline efficiency and reduce operational downtime today.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Our Stainless Steel Gate Valves: Features and Benefits

Durability and Strength

Made from top-grade stainless steel, our gate valves offer excellent resistance to corrosion, high temperatures, and pressure surges, making them an ideal choice for industries where durability is a priority.

- Alloy Options: Choose from CF8, CF3, CF8M, and CF3M to meet your specific process requirements.

- Pressure Ratings: Available in Class 150, Class 300, and Class 600 ratings to ensure compatibility with your pipeline working pressures.

- Temperature Range: Suitable for applications with a temperature range of -29°C to 454°C.

Reliable Performance

Designed for on/off flow control, our stainless steel gate valves provide 100% shutoff, prevent leaks and ensure system integrity. These valves are low maintenance and provide peace of mind even in the most critical systems.

- High Performance: Delivers reliable performance even in extreme temperature and high pressure systems.

- Smooth Flow Control: Designed to minimize turbulence and maximize efficiency, our gate valves help achieve smooth flow control and reduce energy loss.

Multiple End Connection Options

We offer a variety of end connection options, including flanged, threaded and welded, ensuring compatibility with your existing piping system.

Industries We Serve

Our stainless steel gate valves are ideal for use in various industries that require reliable, high-performance valves:

- Chemical Processing: Corrosion-resistant valves that handle aggressive chemicals and extreme temperatures.

- Oil & Gas: Perfect for use in pipelines, refineries, and offshore platforms.

- Water Treatment: Used for regulating water flow in municipal and industrial treatment facilities.

- Food and Beverage: Designed to meet sanitary standards in food production and processing plants.

- Pharmaceuticals: Critical for maintaining hygienic conditions and precise flow control in drug manufacturing.

Types of Stainless Steel Gate Valves

At TOT Valve, we offer a wide selection of stainless steel gate valve types, each designed to meet specific needs in different applications.

Wedge Gate Valves

The most common design, where the gate has a wedge shape that is forced into the seat to create a tight seal.

Parallel Gate Valves

The gate is flat, and both sides of the gate are parallel. These valves are used for lower pressure systems.

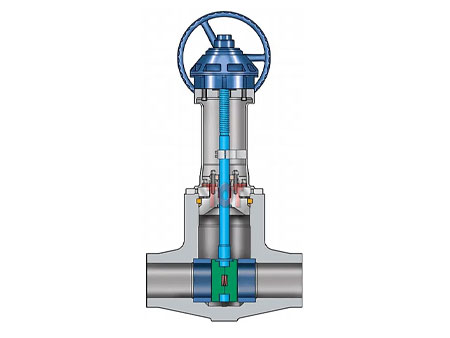

Rising Stem Gate Valves

The stem rises above the valve body when the valve is opened, providing a visual indication of the valve’s status.

Non-Rising Stem Gate Valves

The stem does not rise when the valve is operated, which is useful for installations where space is limited.

FAQ

The operation of a gate valve is quite straightforward:

Opening the Valve: When the valve is opened, the gate is lifted vertically by turning the stem. This lifts the wedge-shaped gate out of the flow path, allowing fluids or gases to pass through the valve with minimal resistance.

Closing the Valve: When the valve is closed, the gate moves downward and seals against the valve seat, completely blocking the flow of the medium. This creates a tight seal to prevent leakage.

As a leading stainless steel gate valve manufacturer, TOT Valve provides more than just products—we deliver solutions. Our focus on quality, performance, and customer satisfaction makes us the preferred choice for companies across various sectors. Here’s why you should work with us:

- Custom Manufacturing: We offer tailored solutions to meet your unique requirements.

- Global Reach: With a robust export network, our products are available worldwide, ensuring timely delivery no matter where you are.

- Expert Support: Our knowledgeable team is here to assist you in choosing the right valves, as well as providing installation and maintenance guidance.