What is a Globe Valve? For Precision Flow Control

A globe valve is a type of linear motion valve designed to start, stop, and regulate fluid flow in pipelines. It gets its name from its traditional globe-shaped body, although modern designs may vary in appearance. Unlike gate valves, which are best for on/off service, globe valves excel in precise flow modulation, making them essential in systems where pressure, flow rate, or temperature must be tightly controlled.

Key Characteristics:

- Linear motion

- Good throttling capability

- Reliable shutoff

- Widely used in high-pressure, high-temperature applications

As a professional valve manufacturer, whether you need Y-type for power plants, cage-guided for high-pressure systems, or angle valves for compact pipelines, TOT ensures optimal performance and long-term durability.

Looking for customized designs, corrosion resistance, or automation-ready options? Let TOT Valve help you specify the perfect globe valve.

Contact TOT Valve today and upgrade your flow control systems with precision and confidence.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

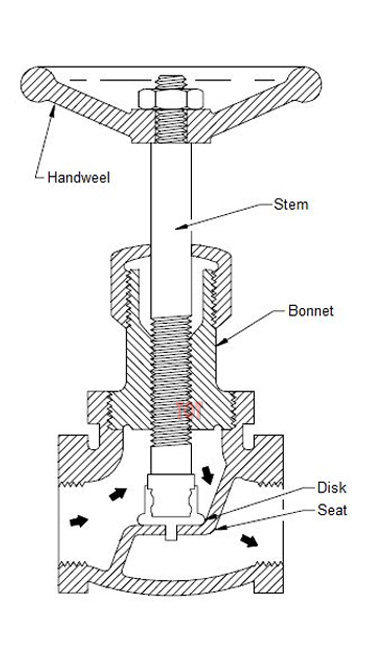

How Does a Globe Valve Work?

Globe valves use a vertically moving disc (plug) that opens or closes the valve seat to control flow. When the handwheel is turned, it raises or lowers the stem, which in turn moves the disc. This linear motion allows for:

- Fine throttling control

- Tight shutoff

- Minimal leakage

Thanks to their construction, globe valves are particularly effective in applications where flow regulation is more important than full bore capacity.

Step-by-Step Operation:

- The operator turns the handwheel.

- The stem moves the disc (plug) up or down.

- The disc moves away from or presses onto the seat to allow or stop flow.

- Packing and gaskets ensure a leak-tight seal during operation.

Globe Valve Key Technical Highlights

Understanding the structural and functional advantages of TOT globe valves helps you choose the right valve for your system:

Operation Mechanism

TOT globe valves utilize manual or automated actuation to vertically move the disc for start, stop, or throttling control.

Core Internal Components

- Disc (Plug/Ball/Composition) – Controls flow rate and shutoff performance

- Stem – Transfers movement from actuator or handwheel to the disc

- Seat – Seals the valve and prevents leakage

- Bonnet – Covers the valve body and holds the stem and packing

- Packing – Seals around the stem to prevent fluid escape

Throttling Advantage

The vertical motion of the disc enables precise flow regulation, especially in cooling water, steam lines, and chemical dosing systems.

Enhanced Designs

- Y-Type: Angled seat reduces pressure drop and turbulence, ideal for high-pressure/high-temperature.

- Angle-Type: Turns flow 90° to simplify piping layouts and save space.

- Cage-Guided: Piston-style disc inside a cage offers stable flow control for high-pressure applications.

Double-Ported: Two opposing discs reduce actuation force, ideal for automated systems.

Types of Globe Valves

Globe valves are essential components in various piping systems. There are many types of globe valves on the market to meet different media, flow characteristics, pressure conditions and installation directions. Here are some common globe valve types and a brief overview that we provide to help you choose the right globe valve.

T-Type Globe Valve (Z-Type)

Y-Pattern Globe Valve

Angle Globe Valve

Cage-Guided Globe Valve

Double-Ported Globe Valve

Bonnet Globe Valve

Advantages of Globe Valves

Precise Throttling: Ideal for applications requiring fine control over flow rate

Leak-Resistant Design: Tight shutoff with minimal leakage even under pressure

Durable Construction: Withstands high pressure, high temperature, and corrosive media

Ease of Maintenance: Accessible internal parts for quick repair or replacement

Application Flexibility: Suitable for manual, electric, or pneumatic operation

Globe Valve vs. Ball Valve

| Aspect | Globe Valve | Ball Valve |

|---|---|---|

| Structure | Disk-shaped closure element with a rising stem, allowing for throttling and precise flow control. Design can cause high-pressure drops. | Spherical closure element with a hole through the center. Simplified design with minimal pressure drop when open. |

| Working Mechanism | Disk moves vertically to open or close the valve. Often used for throttling fluid flow. | Ball rotates 90 degrees to open or close. Provides quick shut-off and is easy to operate. |

| Flow Control | Excellent for flow regulation and throttling applications. Not ideal for full isolation. | Best for on/off control with quick shut-off. Not ideal for throttling in high-pressure situations. |

| Applications | Suitable for applications requiring flow regulation, such as chemical processes, water treatment, and power plants. | Ideal for quick shut-off in emergency situations, often used in oil & gas, HVAC, water treatment, and food processing. |

| Function | Designed for precise flow control and throttling; can handle high-pressure drops. | Designed for isolation; quick opening/closing but not for precise flow control. |

| Valve Material | Common materials include stainless steel, carbon steel, bronze, and cast iron. High-alloy materials for high-pressure applications. | Common materials include stainless steel, brass, carbon steel, PVC, and plastic for low-pressure applications. |

| Cost | Generally more expensive due to the complexity of design and materials. | More cost-effective than globe valves, especially in smaller sizes. |

| Size Range | Typically available in sizes from 1/2 inch to 24 inches. Larger sizes available for industrial applications. | Common sizes range from 1/4 inch to 12 inches, with larger sizes available in full-port designs. |

| Pressure Rating | Suitable for moderate to high-pressure applications, up to 1500 psi depending on the material. | Suitable for low to high-pressure applications, often up to 6000 psi depending on material and design. |

| Durability | Durable but can be prone to erosion and wear due to throttling. Needs regular maintenance. | Generally durable and more resistant to wear in on/off applications. Requires less maintenance but prone to sealing issues over time. |

| Installation Space | Requires more space due to the stem and disk structure. | Compact and can fit in tight spaces, especially in smaller systems. |

| Flow Restriction | High-pressure drop due to the design of the flow path, making it unsuitable for applications with high flow rates. | Minimal flow restriction when fully open, suitable for high-flow applications. |

| Repair & Maintenance | More complex to repair due to the intricate internal parts; requires more expertise. | Easier to repair and maintain due to a simple design. |

FAQ

Globe valves allow precise control over flow and pressure, while gate valves are more suited for on/off applications.

Use Y-Type globe valves when minimizing pressure drop is essential, especially in steam or high-pressure lines.

Yes. The seats and internal parts are easily accessible, and packing can be replaced without removing the valve from the pipeline.

Absolutely. Our globe valves support electric or pneumatic actuators, with optional positioners for precise feedback control.

TOT globe valves serve critical flow control needs in industries where precision and safety are paramount:

Oil & Gas

- Process gas control

- Cooling systems

- Wellhead pressure regulation

Water & Wastewater

- Flow control in filtration and sedimentation

- Dosing and chemical mixing

Power Generation

- Steam and feedwater regulation

- Turbine lubrication systems

Chemical & Petrochemical

- Acid, solvent, and steam control

- Exothermic cooling loops

Heat Transfer & Toxic Fluids

- Shutoff for thermal oil, radioactive, or flammable fluids

- Where safety and tight sealing are critical