Cut Through Challenges, Control the Flow.

What Is a Knife Gate Valve?

A knife gate valve is a type of linear-motion gate valve that features a sharp, blade-like gate designed to slice through thick or abrasive media such as slurries, pulp, wastewater, and powders. Unlike conventional gate valves, knife gate valves are engineered to handle challenging applications with suspended solids, fibrous materials, or high-viscosity flow.

Whether you’re dealing with sludge in wastewater systems, minerals in mining pipelines, or pulp in paper mills, our knife gate valves help you isolate flow quickly, cleanly, and with minimal maintenance.

When your operations demand reliable shut-off in tough, slurry-heavy, or solid-laden environments, you need more than just a standard valve — you need a knife gate valve that performs with precision, durability, and efficiency. At TOT Valve, we design and manufacture industrial-grade knife gate valves that give you control where others fail.

Knife Gate Valve Types

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

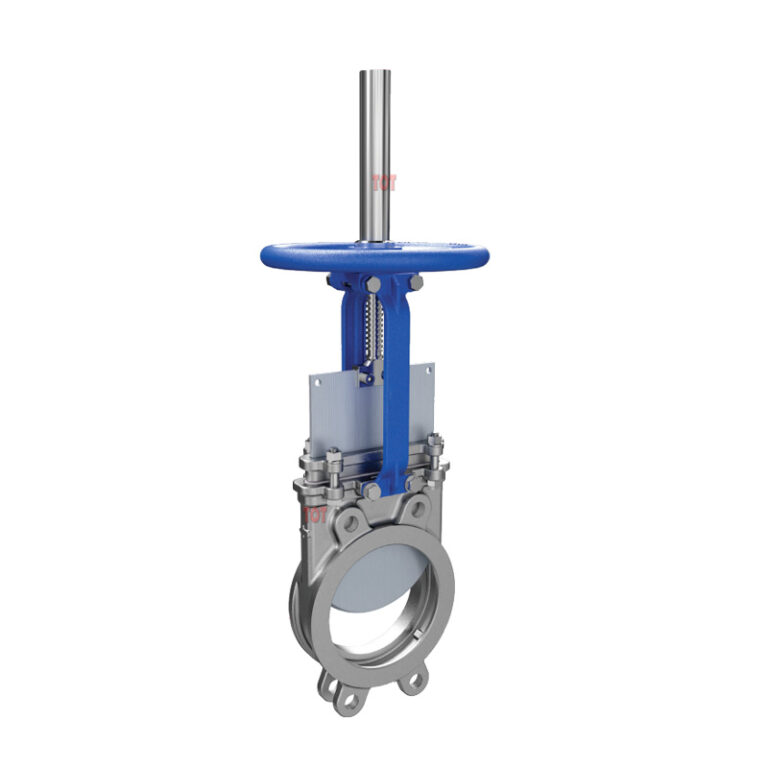

Product Structure: Designed for Performance

Understanding what goes into each TOT knife gate valve helps you appreciate why it performs better in demanding industrial settings:

▸ Valve Body

Made from cast iron, carbon steel, stainless steel, or duplex alloys, the body houses and protects all internal components. Choose the right material for your pressure, temperature, and media conditions.

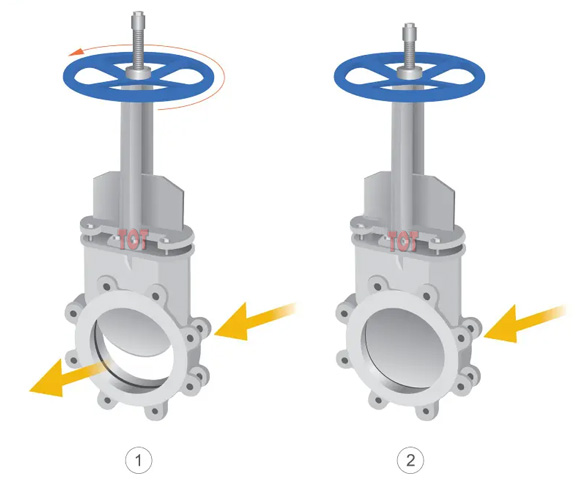

▸ Knife Gate (Blade)

The core feature — a precisely machined metal gate with a beveled edge — cuts through solids and slurry effortlessly while creating a reliable seal when closed.

▸ Seat

Available in metal or soft elastomeric materials, the seat provides a tight seal against the gate. For abrasive applications, we recommend hardened metal seats for extended life.

▸ Stem & Packing Gland

The rising or non-rising stem transfers motion to the gate. Our adjustable packing gland system ensures leak-proof sealing around the stem, even after long-term use.

▸ Actuator Choose from:

- Manual Handwheel – Simple, reliable, cost-effective

- Pneumatic Cylinder – Ideal for fast, repetitive operations

- Electric Actuator – Great for remote or automated control

- Hydraulic Actuator – Best for high-thrust applications

All actuator types offer precise and responsive control — essential for your critical process operations.

Advantages of TOT Valve Knife Gate Valves

You don’t just need a valve — you need a long-term solution. Here’s how our knife gate valves deliver real value:

✔ Reliable Shut-Off in Harsh Conditions

Your media isn’t smooth or predictable — and we get that. Our sharp-edged gate slices through thick slurries, fibrous pulp, and abrasive solids without clogging or sticking.

✔ Built to Last

Manufactured with high-quality stainless steel or carbon steel bodies, our valves resist corrosion, wear, and pressure-related deformation, even in the most aggressive environments.

✔ Customizable to Your Application

Choose from a wide range of materials, sizes, pressure ratings, and actuation options. Whether manual, pneumatic, or electric, we build your valve to fit your system, not the other way around.

✔ Low Maintenance

Thanks to their simple structure and robust design, our knife gate valves reduce the risk of downtime. That means fewer repairs, less cleaning, and more productivity on your end.

Where You’ll Use It: Application Industries

TOT knife gate valves are trusted across industries that require robust flow control in harsh or particulate-laden environments:

Industry | Application Examples |

Mining & Minerals | Tailings transport, ore slurry pipelines, flotation cells |

Pulp & Paper | High-consistency pulp, paper stock, fiber-rich fluids |

Wastewater Treatment | Raw sewage, sludge, biosolids, grit channels |

Power Generation | Fly ash, bottom ash disposal, coal slurry |

Steel & Metallurgy | Slag handling, molten metal, scale-water separation |

Chemical Processing | Corrosive slurries, polymer fluids, abrasive chemicals |

Cement & Aggregates | Sand, gravel, lime slurry, cement powder |

Food & Beverage | Viscous food slurries like tomato paste, starch, and sauces |

Bulk Material Handling | Granules, powders, pneumatic conveying systems |

Dredging & Reclamation | Mud, sand-water mixtures, sediment pipelines |

Knife Gate Valves vs. Traditional Gate Valves

If you’re wondering whether knife gate valves are right for you, here’s how they outperform traditional wedge-type gate valves:

| Feature | Knife Gate Valve | Traditional Gate Valve |

| Media Suitability | Slurry, solids, pulp, fibers | Clean liquids, low-viscosity media |

| Seal Design | Cuts through solids for tight shut-off | Prone to clogging with debris |

| Operating Space | Compact and linear | Bulkier, more space required |

| Maintenance | Low | Higher due to jamming or leakage |

| Cost Efficiency | Ideal for harsh processes | Better for clean systems only |

How to Choose the Right Knife Gate Valve for Your Needs

Every system is different — here’s what to consider when selecting your valve:

✅ Media Type

Are you handling abrasive slurries, fibrous pulp, or dry powder?

Choose metal seats for abrasives, resilient seats for softer sealing, and coatings for corrosion resistance.

✅ Pressure and Temperature

Confirm the valve’s pressure class (e.g., PN10, ANSI 150) and temperature range. Higher ratings demand stronger materials and gaskets.

✅ Valve Size

Available in sizes from 2” to 24” (DN50 to DN600). We match the valve bore to your pipeline dimensions to minimize pressure drop.

✅ Operation Frequency

Frequent cycling? Go with pneumatic or electric actuation. Infrequent? Manual may suffice.

✅ Standards Compliance

We manufacture valves to meet global industrial standards, including: ISO 9001, API 6D / API 600, CE / PED

✅ TOT Valve Material Options

Component | Available Materials |

Body | Cast Iron, WCB, CF8, CF8M, Duplex SS |

Gate | SS304, SS316, Duplex, Hard Coated |

Seat | Metal (SS/Stellite), EPDM, NBR, PTFE |

Stem | Stainless Steel, Chrome-Plated Carbon Steel |

Packing | PTFE, Graphite, Braided Fiber |

You need guidance? Our engineers will help you choose the right configuration based on your media, temperature, and environment.