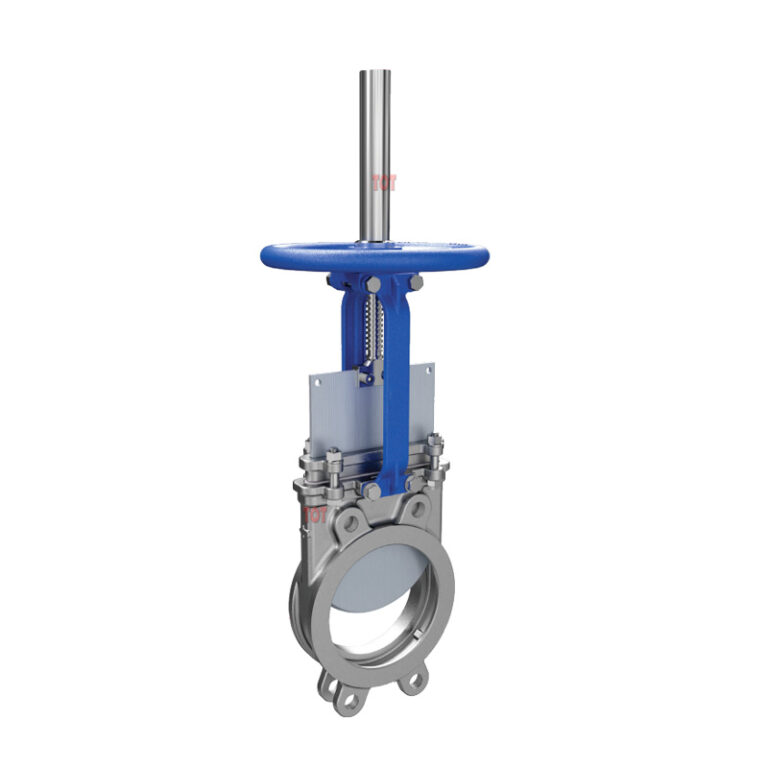

Stainless Steel Knife Gate Valves

When your industrial fluid system handles slurries, wastewater, pulp or powders, you need valves that are not only durable but also cut-off. Designed for abrasive, corrosive and viscous media, our stainless steel knife gate valves provide reliable isolation in harsh environments.

TOT stainless steel knife gate valves are gate valves with a blade-shaped gate that moves perpendicular to the flow direction. Industrial valves designed to control the flow of difficult media such as slurries, viscous liquids, powders and wastewater.

Stainless steel knife gate valves are characterized by a sharp gate – like a blade – that can cut through heavy or rough materials and achieve reliable shutoff.

Made of high-quality stainless steel (CF8/CF3/CF8M/CF3M/Duplex Stainless Steel), these knife valves have enhanced corrosion resistance and are ideal for harsh environments or corrosive fluids.

Full Stainless Steel Body & Gate: Not just wetted parts — the whole body is corrosion-proof.

Customizable for Your Flow System: Face-to-face dimensions, flanges, actuators — we adapt to your project specs.

Factory-Tested Before Delivery: Every valve is hydro and seat tested to meet international standards.

API 6D, CE, and ISO Certified Manufacturing: You’re backed by global-quality compliance and professional manufacturing.

Contact us now, let us help you optimize your pipeline efficiency and reduce operational downtime today.

Let’s Help You Specify the Right Knife Gate Valve

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Stainless Steel Knife Valve Data Sheet

| Parameter | Details |

| Body Material | CF8 / CF8M / Duplex Stainless Steel |

| Gate Material | SS304 / SS316 / 2205 |

| Seat Options | EPDM, PTFE, Metal Seat |

| Packing | PTFE, Graphite, Braided Aramid |

| Pressure Rating | PN10 / PN16 / ANSI 150 |

| Face-to-Face | Allow Customized |

| Connection | Wafer / Lug / Flanged |

| Actuation | Manual, Pneumatic, Electric |

Material Comparison: Stainless Steel vs. Carbon Steel vs. Ceramic-Lined

| Feature | Stainless Steel | Carbon Steel | Ceramic-Lined |

|---|---|---|---|

| Corrosion Resistance | Excellent (esp. SS316) | Poor without coating | Very High |

| Abrasion Resistance | Moderate | Moderate | Superior |

| Cost | Medium | Low | High |

| Weight | Medium | Medium | Heavy |

| Ideal Media | Corrosive + semi-abrasive | Neutral + clean fluids | Highly abrasive + high temp |

| Common Applications | Chemical, F&B, wastewater | Water, oil, general purpose | Mining, ash, slurry pipelines |

| Availability (Lead Time) | Fast (stock available) | Fast | Medium (requires lining) |

Kind Tips: If your priority is corrosion resistance, food-safety compatibility, or mid-level abrasion handling — stainless steel is your best value-for-performance choice.

Why Choose Stainless Steel Knife Gate Valves?

You operate in environments where regular valves fail — corrosion, clogging, or jamming can lead to costly downtime. That’s where stainless steel knife gate valves come in.

- Corrosion-Resistant: Made of high-grade stainless steel (SS304, SS316, or duplex options), these valves resist aggressive media, harsh chemicals, and humid environments.

- Low Maintenance, High Reliability: With a self-cleaning blade and compact design, stainless steel knife gate valves are easy to install, operate, and maintain.

- Designed for Tough Media: Slurries, powders, viscous fluids, and fibrous materials are no match for the sharp-edged gate that cuts through buildup and closes tightly.

How Our Stainless Steel Knife Gate Valves Are Built for Performance

Whether you’re handling wastewater, mining tailings, or pulp stock, your valve’s performance matters. Here’s what you can count on:

1. Full Bore Flow

You get uninterrupted media flow thanks to the unobstructed port when the valve is fully open. That means less turbulence and lower pressure drop.

2. Razor-Sharp Shut-Off

The blade-like gate slices through media and seals reliably — even when there’s slurry or solids in the line.

3. Corrosion-Resistant Construction

Every wetted component is stainless steel, ensuring durability in corrosive or saline conditions — no flaking, no rusting.

4. Multiple Actuation Options

Choose the actuation that fits your operation:

- Manual (Handwheel or Chainwheel)

- Pneumatic Cylinder

- Electric Actuator

5. Resilient & Metal Seat Options

Whether you need bubble-tight sealing or metal-to-metal ruggedness, we provide seat materials that match your needs.

6. Zero Leakage to Atmosphere

With gland packing and optional O-ring or scraper rings, our valves are sealed tight — inside and out.

Available Sizes & Pressure Ratings

- Size Range: DN50–DN1200 (2″–48″)

- Pressure Class: PN10 / ANSI 150 / custom available

- Temperature Range: Up to 250°C depending on seat and packing

Applications You Can Trust It In

Stainless steel knife gate valves are the go-to solution in:

- Pulp & Paper: Handles fibrous slurries and stock with minimal clogging

- Wastewater Treatment: Cuts through sludge and debris with ease

- Mining & Minerals: Withstands abrasive tailings and slurry media

- Power Plants: Controls ash and chemical-laden fluids

- Food & Beverage: Suitable for clean-in-place and sanitary environments (optional polish)

- Chemical Processing: Resists corrosion from aggressive media

Optional Features for Enhanced Performance

- Purge Ports: For flushing and cleaning sticky media

- Position Indicator: For remote operation feedback

- Extended Stem or Gearbox: For deep wells or remote access

- Dust Covers & Scrapers: Prevents media buildup on stem and sealing surfaces

* We are not just providing simple quotes but experts in selection, calculation, and drawing.

FAQ

A stainless steel knife gate valve is a type of valve designed to control the flow of abrasive, slurry, or viscous fluids. It features a sharp-edged gate that slices through materials and provides reliable shut-off, often used in industries like wastewater treatment, mining, and pulp & paper. The stainless steel construction provides excellent corrosion resistance, making it suitable for harsh environments.

These valves are ideal for handling media like:

- Slurries

- Wastewater

- Pulp and paper stock

- Abrasive materials

- Chemicals and oils

- Powdery or granular substances

They are particularly useful in applications where the media contains solid particles or is thick and viscous.

The valve works by using a sharp-edged gate that moves vertically up and down. When the valve is open, the gate is lifted completely, allowing the media to flow freely. When closed, the gate moves down and cuts through any debris or solids, providing a reliable seal to stop the flow.

When selecting the appropriate valve, consider the following:

- Size and Pressure Rating: Choose a valve size that fits your pipeline and matches your system's pressure requirements.

- Media Type: Ensure the valve’s seat and gate material are compatible with the type of media it will handle (abrasive, chemical, etc.).

- Actuation Type: Select manual, pneumatic, or electric actuation based on your system's automation needs.

- Temperature Range: Verify that the materials used can withstand the operating temperature.

Knife gate valves are generally low-maintenance, but regular checks should include:

- Inspecting for wear or damage to the gate and seat

- Cleaning the valve to prevent buildup of debris or corrosive material

- Lubricating the stem or packing to ensure smooth operation

- Checking for leaks around the gland and actuator

Yes, knife gate valves can be automated with pneumatic or electric actuators. Automation helps with remote control, reducing manual effort and improving operational efficiency in large-scale or hazardous environments.