Stainless Steel Strainer Manufacturers

A Stainless Steel Strainer is a filtration device, the primary purpose of these strainers is to protect sensitive equipment like pumps, valves, and compressors by preventing harmful solids from entering the system and causing damage or blockages.

Stainless steel is a preferred material for TOT strainers due to its corrosion resistance, strength, and durability. In addition to stainless steel, we offer a wide range of alloys and materials, ensuring that your strainer is tailored to your specific needs.

Our Stainless Steel Strainers are designed to filter out debris, solids, and other contaminants that could damage your system and downstream equipment. That help you achieve efficient filtration for various media types, including liquids, steam, and gases.

Available in a variety of designs, including Y-type strainers, Basket strainers, and Tee-type strainers, our collection offers flexibility and versatility for a range of industrial applications. Whether you’re in oil & gas, water treatment, petrochemical, or food industries, we have the right strainer solution to meet your unique needs.

All of our strainers undergo rigorous testing to ensure they meet ANSI standards and perform reliably in your system.

Contact us now, let us help you optimize your pipeline efficiency and reduce operational downtime today.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

What Makes Our Strainers Ideal for Your Business?

Durable Construction: Our strainers are made from corrosion-resistant stainless steel, ensuring a long lifespan even in the most demanding environments. This construction resists wear and tear, reducing the need for frequent maintenance and minimizing downtime.

High Pressure Resistance: Built to withstand up to 150-lbs pressure ratings, our strainers are ideal for high-pressure applications, ensuring reliable performance over time.

Customizable Solutions: Choose from a range of sizes, mesh configurations, and material options to tailor the perfect strainer for your specific requirements. Whether you need a perforated mesh or wedge wire, we’ve got you covered.

Efficient Filtration: The mesh size and open area ratio (OAR) of our strainers ensure optimal filtration performance. By selecting the right mesh size, you can filter out particles with precision, reducing risks of clogs and damage to downstream equipment.

Why Your Pipeline Needs Our Strainers

Strainers serve as the first line of defense for your entire system. By catching debris and preventing larger particles from entering the pipeline, strainers safeguard your pumps, valves, and other critical components. Not only does this help avoid costly repairs, but it also reduces maintenance efforts and extends the lifespan of your equipment.

Improved System Efficiency: By using our strainers to remove foreign debris and contaminants, you ensure that your system remains efficient, minimizing energy consumption and preventing equipment malfunctions.

Protection Against Damage: Whether you’re dealing with steam, liquids, or gases, our strainers help protect downstream equipment by filtering harmful solids from the flow media. This protects your valves, compressors, and pumps from damage, extending their operational lifespan.

Lower Operational Costs: With our strainers in place, you can reduce the frequency of maintenance and repairs, resulting in lower operational costs and less downtime for your business.

Strainer Types to Match Your Specific Needs

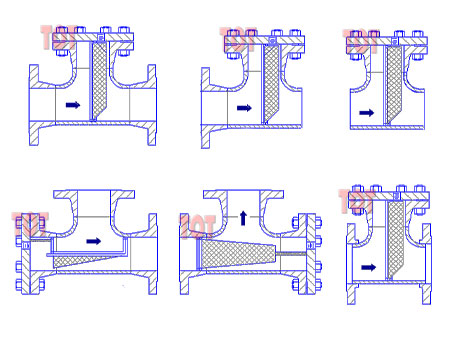

At TOT Valve, we offer a wide selection of Strainer Types, each designed to meet specific needs in different applications.

Y-Type Strainers

Ideal for applications with low particulate content, these strainers are effective at removing smaller debris and can be installed in either vertical or horizontal orientations. They’re commonly used in steam, air, and natural gas systems, as well as in applications that require frequent maintenance.

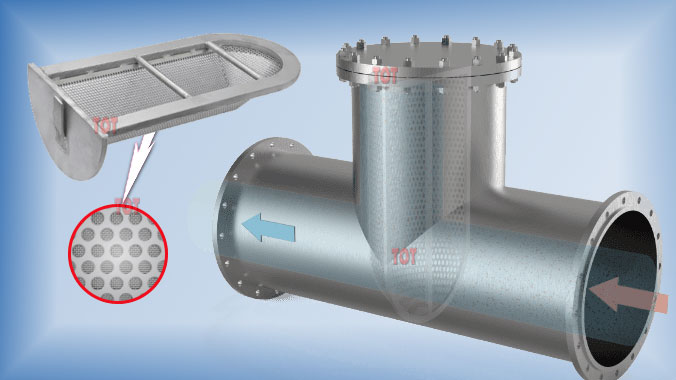

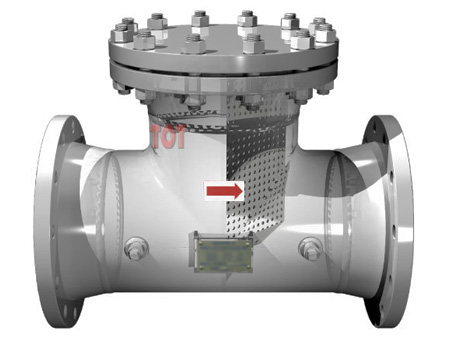

Basket Strainers

When dealing with heavier particulate matter or media that requires less frequent cleaning, our Basket Strainers offer larger filtration areas and can handle higher volumes of debris. They are perfect for industrial water systems, combustion oil applications, and other systems with larger solids.

Tee-Type Strainers

These are best used in applications with medium to large particulate matter. Their design allows for easy installation and efficient filtration without taking up excessive space.

Special Application Strainers

For specific needs, we offer customized strainers, including High Capacity Basket Strainers, Magnetic Strainers, and Jacketed Strainers. These options are perfect for high-pressure applications, water separation, or for use in extreme temperature environments.

Selecting the Right Strainer for Your Application

Choosing the right strainer is crucial to maintaining optimal system performance. When selecting a strainer, consider these key factors:

Flow Rate: Your strainer must be sized according to the flow rate of the system. For high-flow applications, Basket Strainers are ideal, as they cause less pressure drop than other types.

Mesh Size: Depending on the level of filtration required, you can select the appropriate mesh size. A finer mesh offers better filtration but may cause higher pressure drops. We help you choose the perfect mesh size based on your system’s needs.

Pressure and Temperature Ratings: Make sure the strainer you choose can withstand the pressure and temperature of your system. Our strainers are designed to perform under high pressure and extreme conditions.

Maintenance: Consider the maintenance frequency required for the strainer. Some applications might benefit from strainers that are easier to clean and maintain.

Materials and End Connections: To ensure compatibility with your system, our strainers are available in a range of materials, including carbon steel, stainless steel, and forged steel, with various end connections like flanged, threaded, and butt-weld options. This ensures a perfect fit for your piping system.

Corrosion Resistance: Stainless steel strainers are ideal for applications exposed to corrosive materials, providing you with long-lasting performance and protection against rust and degradation.

FAQ

A Y-type strainer is typically used for smaller pipelines or when space is limited. It is designed to filter smaller particles and is suitable for applications where the strainer does not need to hold large amounts of debris. It's usually installed in vertical pipelines.

A basket strainer has a larger filtering area and can hold more debris, making it ideal for applications with higher flow rates or larger particles. It is typically installed in horizontal pipelines and is easier to clean, making it a better choice for continuous flow systems.

Stainless steel strainers are commonly used in various industrial applications, including:

- Oil & Gas: To filter contaminants from fuel and gas systems.

- Water Treatment: To purify water before it enters the filtration process.

- Petrochemical: To prevent solids from damaging sensitive equipment.

- Food Processing: To ensure the cleanliness of liquids in food production.

When selecting the right stainless steel strainer, consider the following factors:

- Flow Rate: Determine the required flow rate for your application. If you have a high flow rate, a basket strainer may be a better choice, while a Y-type strainer is suitable for smaller flows.

- Particle Size: Identify the size of particles you need to filter out. Choose a mesh size that can effectively capture these particles without causing excessive pressure drop.

- Pressure Rating: Ensure the strainer can handle the pressure in your system. Stainless steel strainers are typically rated for high-pressure applications, but you should still check the specifications.

- Pipeline Orientation: The orientation of your pipe (vertical or horizontal) may impact which type of strainer to choose. Y-type strainers are often used for vertical installations, while basket strainers are better for horizontal pipes.

By assessing these factors, you can ensure the strainer you choose will meet the demands of your specific system.

The frequency of cleaning your stainless steel strainer depends on the type of system and the level of contamination in the media you're filtering. If you're using a Y-type strainer, it may need to be cleaned more frequently since it holds less debris. In contrast, basket strainers typically need less frequent cleaning because they have a larger mesh area and can hold more debris.

You should inspect and clean the strainer when you notice a drop in flow rate or pressure, or if the strainer becomes clogged with particles. Regular maintenance will prolong the lifespan of your strainer and prevent system damage.

Yes, stainless steel strainers are highly resistant to high pressures and are specifically designed for industrial applications that require robust filtration. Depending on the design, many stainless steel strainers can withstand pressure ratings of up to 150 PSI and beyond. Their corrosion resistance and durability make them ideal for industries like oil & gas, petrochemical, and water treatment, where high pressure is common.

If you're working in an extremely high-pressure environment, be sure to choose a strainer with the appropriate pressure rating and size for your system.

Yes, customization options are available for stainless steel strainers to meet specific industrial requirements. Depending on your needs, strainers can be tailored in terms of mesh size, material type, end connections, and size. Whether you need a custom Y-type or basket strainer, our team can work with you to design the perfect solution for your system.

If you have special filtration requirements, feel free to reach out, and we can provide a tailored solution that fits your exact specifications.