API Globe Valve

API globe valve is a forced sealing valve, usually used as an isolation valve for the medium, and its opening and closing parts (valve discs) move up and down along the center line of the valve seat channel. Since the flow area of the valve seat is proportional to the opening and closing stroke of the opening and closing parts, our valves can properly adjust the flow for your application, but when you have special requirements for flow characteristics, you should carefully consider whether the globe valve itself can be used as a control valve.

If you have any questions, please contact our sales manager immediately, because we are a professional globe valve manufacturer and exporter.

Description

American globe valves mainly include API, ASME and ASTM standards.

ASTM is a material standard, not a standard for the valve itself.

TOT globe valves designed, manufactured, produced and tested completely in accordance with API standards are called API globe valves.

API globe valve is a forced sealing valve, usually used as an isolation valve for the medium, and its opening and closing parts (valve discs) move up and down along the center line of the valve seat channel.

Since the flow area of the valve seat is proportional to the opening and closing stroke of the opening and closing parts, our valves can properly adjust the flow for your application, but when you have special requirements for flow characteristics, you should carefully consider whether the globe valve itself can be used as a control valve.

If you are interested in purchasing API Globe Valve from China, TOT Valve will not disappoint you, because we are a professional valve manufacturer and supplier. Not only can we provide you with ODM and OEM services, but also provide you with the most favorable ex-factory price for free. Contact us now to get globe valve prices!

Product Advantages

– Small fluid resistance, its resistance coefficient is equal to that of the pipe section of the same length.

– Simple structure, small size and light weight.

– Tight and reliable, the sealing surface material of the globe valve is currently widely plastic, with good sealing performance, and has been widely used in vacuum systems.

– Easy to operate, quick opening and closing, from full open to full closed, only need to rotate 90°, which is convenient for remote control.

– Easy maintenance and simple structure, the sealing ring is generally movable, and it is convenient to disassemble and replace.

– When fully open or fully closed, the sealing surface of the valve body and the valve seat is isolated from the medium, and the medium will not cause erosion of the valve sealing surface when passing through.

– Wide range of applications, the diameter ranges from a few millimeters to several meters, and can be applied from high vacuum to high pressure. When the ball rotates 90 degrees, the inlet and outlet should all present spherical surfaces, thereby cutting off the flow.

– Widely used in petrochemical, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

API Globe Valve Standard

The API Globe Valve produced by TOT Valve is manufactured in full accordance with API standards, including design, length and flange connection dimensions. We strictly inspect and test them according to the pressure and temperature under ANSI B16.34 standards to ensure that you get almost the same service life in different application environments.

| Design Spec | Face to Face | Flange Dimension | Welding Connection | Pressure-Temp | Inspection & Test |

| ANSIB16.34 BS1873 | ANSIB16.10 | ANSI B16.5 | ANSIB16.25 | ANSIB16.34 | API598 |

API Globe Valve Pressure Test

TOT applies pressure to the Globe Valve in one direction according to the API standard, and the pressure is applied below the valve disc for pressure testing. The following is our summary of the pressure test results for your reference to ensure that you avoid unnecessary losses due to excessive pressure during your application.

Contact us now for more detailed information!

| Nominal Pressure PN (Lb) | Strength Test | Water Tightness Test | Airtightness Test | |||

|---|---|---|---|---|---|---|

| MPa | Lbf/in² | MPa | Lbf/in² | MPa | Lbf/in² | |

| 150 | 3.0 | 430 | 2.2 | 315 | 0.4-0.7 | 60-100 |

| 300 | 7.7 | 1110 | 5.7 | 815 | ||

| 600 | 15.3 | 2220 | 11.3 | 1630 | ||

| 900 | 23.0 | 3330 | 17.0 | 2445 | ||

| 1500 | 38.4 | 5560 | 28.2 | 4080 | ||

| 2500 | 64.0 | 9255 | 47.0 | 6790 | ||

Main Parts Material and Performance

The TOT API Globe Valve are cast or forged from a variety of high-quality materials, including stainless steel (CF8, CF3, CF8M, CF3M), cast steel, alloy steel , PTFE and Graphite, depending on the requirements of your globe valve application scenario.

If you are interested in our globe valve materials, you can contact us by leaving your information in the form on the right.

| Body Bonnet | Stem | Sealing surface | Shim (Ring) | Packing | Working Temperature | Suitable Medium |

|---|---|---|---|---|---|---|

| WCB | 2Cr13 | CF8 13Cr STL Nylon |

Graphite 13Cr SFB-208 F304 F316 F304L F316L |

Graphite | ≤ 425 | Water, Steam, Oil |

| WC1 | 38CrMoAl 25Cr2MoV |

≤ 425 | ||||

| WC6 | ≤ 540 | |||||

| WC9 | ≤ 570 | |||||

| C5 C12 | ≤ 540 | |||||

| CF8 | F304 | ≤ 200 | Urea Nitrate Acetate | |||

| CF8M | F316 | |||||

| CF3 | F304L | |||||

| CF3M | F316L |

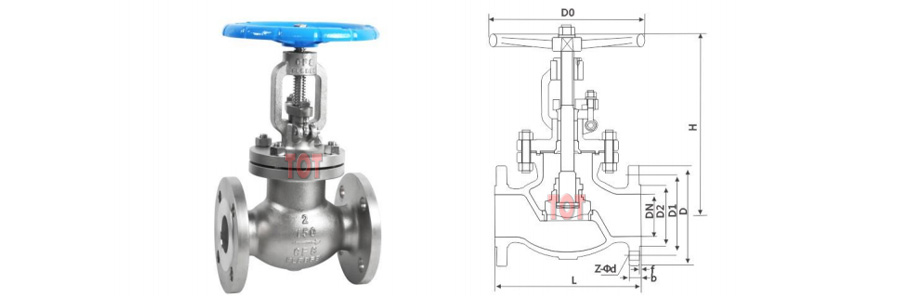

Main External and Connection Dimension

TOT Valve can provide you with API Globe Valve of various sizes and models. We list all existing API Globe Valve Sizes.

The data we provide can be used for your reference. If you do not have the globe valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

Class 150LB API Globe Valve Size

| DN | L | D | D1 | D2 | b | N-Φd | H | D0 | |

|---|---|---|---|---|---|---|---|---|---|

| mm | in | ||||||||

| 15 | 1/2 | 108 | 89 | 60.5 | 35 | 11.2 | 4-Φ16 | 241 | 100 |

| 20 | 3/4 | 117 | 98 | 69.9 | 43 | 12.7 | 4-Φ16 | 241 | 100 |

| 25 | 1 | 127 | 108 | 79.2 | 51 | 14.2 | 4-Φ16 | 242 | 125 |

| 32 | 1-1/4 | 140 | 117 | 89 | 63 | 16 | 4-Φ16 | 280 | 160 |

| 40 | 1-1/2 | 165 | 127 | 98.6 | 73 | 17.5 | 4-Φ16 | 286 | 160 |

| 50 | 2 | 203 | 152 | 120.7 | 92 | 19 | 4-Φ19 | 368 | 200 |

| 65 | 2-1/2 | 216 | 178 | 139.7 | 105 | 22.4 | 4-Φ19 | 387 | 200 |

| 80 | 3 | 241 | 190 | 152.4 | 127 | 24 | 4-Φ19 | 411 | 250 |

| 100 | 4 | 292 | 229 | 190.5 | 157 | 24 | 4-Φ19 | 454 | 250 |

| 125 | 5 | 356 | 254 | 216.0 | 186 | 24 | 8-Φ22.5 | 455 | 350 |

| 150 | 6 | 406 | 279 | 241.3 | 216 | 25.4 | 8-Φ22.5 | 541 | 350 |

| 200 | 8 | 495 | 343 | 298.5 | 270 | 28.4 | 8-Φ22.5 | 651 | 450 |

| 250 | 10 | 622 | 406 | 362.0 | 324 | 30.2 | 12-Φ25.4 | 800 | 450 |

| 300 | 12 | 698 | 483 | 431.8 | 381 | 32 | 12-Φ25.4 | 1231 | 600 |

| 350 | 14 | 787 | 533 | 476.3 | 413 | 35 | 12-Φ29 | 1450 | 600 |

| 400 | 16 | 914 | 597 | 539.8 | 470 | 36.6 | 16-Φ29 | 1645 | 600 |

Class 300LB API Globe Valve Size

| DN | L | D | D1 | D2 | b | N-Φd | H | D0 | |

|---|---|---|---|---|---|---|---|---|---|

| mm | in | ||||||||

| 15 | 1/2 | 152 | 95 | 66.5 | 35 | 14.2 | 4-Ф16 | 241 | 140 |

| 20 | 3/4 | 178 | 117 | 82.5 | 43 | 16 | 4-Ф19 | 241 | 140 |

| 25 | 1 | 203 | 123 | 89 | 51 | 17.5 | 4-Ф19 | 283 | 160 |

| 32 | 11/4 | 216 | 133 | 98.5 | 63 | 19 | 4-Ф19 | 320 | 200 |

| 40 | 11/2 | 229 | 155 | 114.3 | 73 | 20.6 | 4-Ф22.5 | 322 | 200 |

| 50 | 2 | 267 | 165 | 127 | 92 | 22.4 | 8-Ф19 | 399 | 200 |

| 65 | 2 1/2 | 292 | 190 | 149.4 | 105 | 25.4 | 8-Ф22.5 | 438 | 250 |

| 80 | 3 | 318 | 210 | 168.1 | 127 | 28.4 | 8-Ф22.5 | 464 | 280 |

| 100 | 4 | 356 | 254 | 200.2 | 157 | 31.8 | 8-Ф22.5 | 565 | 350 |

| 125 | 5 | 400 | 279 | 235 | 186 | 35 | 8-Ф22.5 | 614 | 350 |

| 150 | 6 | 444 | 318 | 269.7 | 216 | 36.6 | 12-Ф25.4 | 717 | 400 |

| 200 | 8 | 559 | 381 | 330.2 | 270 | 41.2 | 12-Ф25.4 | 930 | 500 |

| 250 | 10 | 622 | 444 | 387.4 | 324 | 47.8 | 16-Ф28.5 | 1012 | 550 |

| 300 | 12 | 711 | 521 | 450.8 | 381 | 50.8 | 16-Ф32 | 1231 | 600 |

| 350 | 14 | 838 | 584 | 514.4 | 413 | 54 | 20-Ф32 | 1450 | 600 |

| 400 | 16 | 864 | 648 | 571.5 | 470 | 57.2 | 20-Ф35 | 1645 | 600 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.