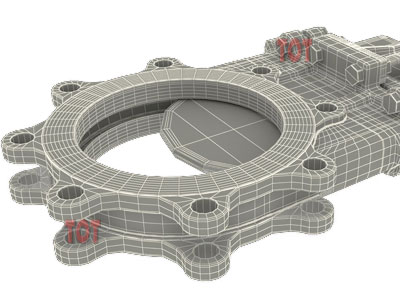

Bidirectional Knife Gate Valve

Bidirectional knife gate valves are also called two-way knife gate valves or double-acting knife gate valves. At TOT Valve, this type of knife gate valve is mainly made of high-quality stainless steel.

If you’re handling slurry, pulp, or solid-laden fluids where flow direction isn’t always predictable, you need a valve that won’t compromise. Our Bidirectional Knife Gate Valve is engineered for zero-leakage shut-off in both flow directions, offering long-term reliability and easy integration into your existing pipeline.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

This bidirectional valve is designed with a precision-machined cast body and a sharp-edged gate to cut through tough media like sludge, fiber, or abrasive slurries. Its dual-sealing system ensures tight shutoff from either direction, making it ideal for complex processing systems where flow reversals are common.

Built for industries that demand performance in extreme conditions—like mining, wastewater, pulp and paper, and chemical processing—this valve guarantees uptime and system efficiency.

Get a quote now and let us help you find the right bidirectional knife gate valve for your application in the shortest possible time.

Bidirectional Knife Gate Valve Features

- Dual-direction sealing – Zero leakage from either side of the valve

- Full-port, unobstructed flow – Reduces pressure loss and prevents clogging

- Heavy-duty gate – Cuts through solids, pulp, or fibrous slurries effortlessly

- Compact, space-saving design – Easy to install or retrofit into tight piping systems

- Self-cleaning seat – Prevents material buildup and reduces maintenance frequency

- Flexible actuation options – Manual, pneumatic, electric, or hydraulic

- Long Service Life – Rugged stainless-steel components resist corrosion and wear

- Lower Operating Costs – Minimal maintenance and quick seal replacement

Main Technical Parameters & Performance

| Bottom-flush design, no cavity, U-type rubber side sealing, one-piece (two-half) construction | |

|---|---|

| Size Range | DN50 – DN600; NPS: 2″-24″ |

| Pressure Rating | PN10, PN16, ANSI 150Psi, 5K/10K |

| Actual Working Pressure | DN50–DN300: 10 Bar; DN350–DN450: 8 Bar; DN500–DN600: 6 Bar |

| Flange Standards | GB/T9113-2010, HG/T20592-2009, HG/T20615-2009, EN1092-2002, ASME B16.5-2013, ASME B16.47-2011, AS2129-2000, AS4087-2004, JIS B2220-2004 |

| Testing Standards | MSS SP-81 (Hydrostatic zero leakage) |

| Body Materials | GGG40, WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature-Pressure Rating Standards | GB/T12224-2007, ASME B16.34-2009, ISO7005-1 |

| Applications | Mining, Chemical Industry, Pharmaceuticals, Potable Water, Wastewater Treatment, Urban Drainage |

| Actuation Options | Manual, Pneumatic, Electric, Gear Drive, Chain Drive |

Bidirectional Knife Gate Valve Main Components and Materials

| Part | Material |

| Body | WCB, CF8, CF8M |

| Disc | 304SS |

| Seat | Viton/EPDM |

| Packing | PTFE |

| Gland | WCB |

| Bracket | 45# Steel |

| Stem | 2Cr13 |

| Stem Nut | Brass |

| Bearing | 65Mn |

| Support Base | WCB |

| Handwheel | GGG30 |

| Stem Cover | 304SS |

| Fasteners | A2–70 |

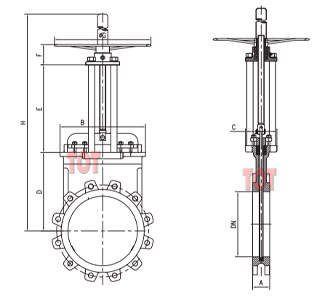

Bidirectional Knife Gate Valve Dimensions

Custom dimensions available upon request. Below is a reference for standard sizes.

| Size | A | B | C | D | E | F | G | H | |

|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | ||||||||

| 50 | 2″ | 48 | 130 | 106 | 105 | 129 | 85 | 180 | 400 |

| 65 | 2-1/2″ | 48 | 145 | 106 | 125 | 147 | 85 | 180 | 446 |

| 80 | 3″ | 51 | 160 | 106 | 140 | 168 | 85 | 200 | 497 |

| 100 | 4″ | 51 | 180 | 106 | 155 | 192 | 85 | 200 | 565 |

| 125 | 5″ | 57 | 210 | 120 | 185 | 215 | 87 | 250 | 655 |

| 150 | 6″ | 57 | 250 | 120 | 200 | 245 | 87 | 280 | 720 |

| 200 | 8″ | 70 | 310 | 130 | 225 | 302 | 95 | 320 | 880 |

| 250 | 10″ | 70 | 330 | 140 | 275 | 355 | 105 | 350 | 1045 |

| 300 | 12″ | 76 | 380 | 160 | 325 | 401 | 105 | 400 | 1175 |

| 350 | 14″ | 76 | 440 | 180 | 370 | 465 | 117 | 450 | 1345 |

| 400 | 16″ | 89 | 490 | 180 | 435 | 511 | 117 | 450 | 1505 |

*Note: DN400 and above use flat flanges.

Applications That Require High Reliability

You’ll benefit most from this valve if you’re in:

- Pulp & Paper – Handles high-density pulp without clogging

- Mining & Minerals – Withstands abrasive slurries and tailings

- Chemical Processing – Offers resistance to corrosive fluids

- Wastewater Treatment – Ideal for sludge and backflow scenarios

- Power Plants – Performs well with fly ash and cooling water systems

FAQ

What is the difference between a bidirectional and a unidirectional knife gate valve?

A bidirectional knife gate valve is designed to provide a tight shut-off in both flow directions, making it suitable for applications where flow reversal may occur. In contrast, a unidirectional knife gate valve allows flow in only one direction and may leak if backflow occurs.

In which industries are bidirectional knife gate valves commonly used?

Bidirectional knife gate valves are widely used in industries such as mining, pulp and paper, wastewater treatment, chemical processing, and power generation. Their ability to handle abrasive slurries and provide reliable shut-off in both directions makes them ideal for these applications.

Can bidirectional knife gate valves handle abrasive or corrosive media?

Yes, these valves are designed to handle abrasive and corrosive media. Materials like stainless steel for the valve body and gate, along with specialized seat materials, enhance their durability and resistance to harsh substances.

What are the available actuation options for bidirectional knife gate valves?

Bidirectional knife gate valves can be actuated manually (handwheel or lever), pneumatically, electrically, or hydraulically, depending on the application’s requirements.

How should I select the appropriate bidirectional knife gate valve size and pressure rating?

Selection depends on factors like pipeline diameter, operating pressure, temperature, and the nature of the media. Consulting with a valve specialist or referring to detailed product specifications can aid in making the right choice.

TOT Are bidirectional knife gate valves compliant with industry standards?

TOT Valve bidirectional knife gate valves comply with standards such as MSS-SP-81 and ASME B16.5, ensuring quality and compatibility with existing systems.

What maintenance practices are recommended for bidirectional knife gate valves?

Regular inspection for wear, ensuring clean sealing surfaces, and proper lubrication of moving parts are essential. Following the manufacturer’s maintenance guidelines will ensure optimal performance and longevity.

Can bidirectional knife gate valves be installed in any orientation?

While some valves can be installed in various orientations, it’s generally recommended to install them vertically with the actuator on top to ensure proper operation and longevity.

What materials are used in constructing bidirectional knife gate valves?

Common materials include stainless steel for the body and gate, with seats made from elastomers or metal, depending on the application’s requirements.

Do bidirectional knife gate valves offer zero-leakage performance?

High-quality bidirectional knife gate valves are designed to provide tight shut-off, minimizing leakage. However, the actual performance may vary based on the specific design and operating conditions.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.