Bonneted Knife Gate Valve

When your operation demands zero leakage, high durability, and maximum safety, you need a valve that’s engineered for reliability. Our Bonneted Knife Gate Valve is purpose-built for challenging applications like slurry, wastewater, and corrosive chemical processing. Whether you’re managing a complex industrial system or specifying components for a new project, this valve offers the performance you can trust.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

This bonneted knife gate valve is designed to eliminate leakage through the stem area and extend valve life in demanding service conditions. With a fully enclosed bonnet, corrosion-resistant materials, and a low-maintenance design, it delivers both operational efficiency and long-term reliability. You’ll find TOT bonneted knife gate valve ideal for applications where safety and consistent performance are critical.

Bonneted Knife Gate Valve Features

- Full Bonnet Design – Prevents external leakage and protects stem and packing.

- Bidirectional Shutoff – Ensures tight sealing in both flow directions.

- Replaceable Seat Options – Soft and metal seats available to match your process needs.

- Corrosion & Abrasion Resistance – Available in SS316, duplex stainless steel, and other alloys.

- Live-Loaded Packing – Maintains seal integrity even under thermal cycling or vibration.

- Custom Actuation – Choose from manual, pneumatic, electric, or hydraulic operation.

Bonneted Knife Gate Valve Core Advantages at a Glance

| Advantage | Benefit to You |

| Zero Leakage | Keeps hazardous or valuable media fully contained. |

| Easy Maintenance | Field-replaceable components reduce downtime. |

| Built to Last | Resists corrosion, abrasion, and pressure shock. |

| Versatile Integration | Compatible with various pipeline standards and actuator types. |

| Custom-Configurable | Options for materials, seats, port flushing, and accessories. |

Bonneted Knife Gate Valve Main Technical Parameters & Performance

| Unidirectional metal seated knife gate valve, rising stem structure, bonneted design, PTFE packing with gland, fully enclosed body to ensure zero leakage. | |

|---|---|

| Design & Manufacturing Standard | MSS SP-81 |

| Size Range | DN50–DN2000 (NPS: 2″~80″) |

| Pressure Ratings | PN10, PN16, ANSI 150Psi, 5K / 10K |

| Actual Working Pressure | DN50–DN250: 10Bar; DN300–DN450: 7Bar; DN500–DN1200: 2Bar; DN1400–DN2000: 1Bar |

| Structural Length Standard | GB/T12221–2005, ASME B16.10 |

| Flange Connection Standard | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2007, JIS B2220–2004 |

| Inspection & Testing Standard | MSS SP–81 |

| Body Material Options | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Sealing Surface / Seat Material | Hard alloy, EPDM, etc. |

| Applicable Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Applications | Mining, metallurgy, chemical, power, medical, paper, water treatment, wastewater, urban drainage, hydro project |

| Actuation Methods | Manual, Pneumatic, Electric, Hydraulic, Electro-hydraulic |

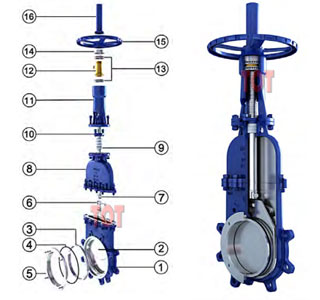

Bonneted Knife Gate Valve Main Components and Materials

| Part | Materials | ||

|---|---|---|---|

| Body | WCB | CF8 | CF8M |

| Disc | 304 | 304 | 316 |

| Seat | Hard Seal or EPDM | ||

| O-ring | NBR | ||

| Seat Cover | WCB | CF8 | CF8M |

| Stem Connector | 2Cr13 | 304 | 316 |

| Stem | 2Cr13 | 304 | 316 |

| Bonnet | WCB | CF8 | CF8M |

| Packing | PTFE | ||

| Gland Flange | WCB | CF8 | CF8M |

| Bracket | WCB | CF8 | CF8M |

| Stem Nut | Brass | Brass | Brass |

| Pin | 65Mn | 65Mn | 65Mn |

| Bearing Bush | #45 | #45 | #45 |

| Handwheel | GGG30 (Epoxy Coated) | ||

| Stem Guard | 304 | 304 | 304 |

| Fasteners | A2–70 | A2–70 | A4–70 |

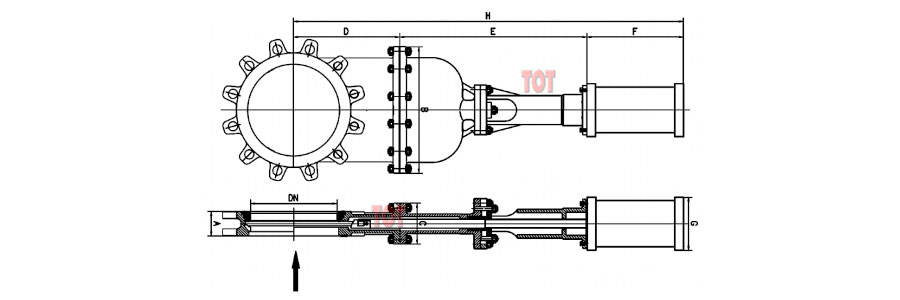

Pneumatic Bonneted Knife Gate Valve Dimensions

We list product dimensions for DN100–DN600 bonneted knife gate valve, and TOT Valve can also provide you with detailed drawings upon request.

| Dimensions | A | B | C | D | E | F | G | H | Cylinder size | Air inlet size | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | ||||||||||

| 100 | 4″ | 51 | 202 | 100 | 145 | 295 | 270 | 120 | 650 | C80/110 | F1/4 |

| 125 | 5″ | 57 | 245 | 105 | 180 | 305 | 290 | 150 | 730 | C100/135 | F1/4 |

| 150 | 6″ | 57 | 285 | 110 | 210 | 410 | 320 | 150 | 795 | C125/160 | F1/4 |

| 200 | 8″ | 70 | 320 | 120 | 245 | 502 | 370 | 195 | 970 | C160/210 | F3/8 |

| 250 | 10″ | 70 | 365 | 125 | 280 | 595 | 420 | 240 | 1135 | C160/260 | F3/8 |

| 300 | 12″ | 76 | 430 | 135 | 290 | 695 | 470 | 280 | 1275 | C200/310 | F3/8 |

| 350 | 14″ | 76 | 490 | 145 | 320 | 850 | 525 | 285 | 1450 | C230/400 | F3/8 |

| 400 | 16″ | 89 | 560 | 160 | 350 | 950 | 570 | 395 | 1620 | C250/460 | F3/8 |

| 450 | 18″ | 89 | 610 | 175 | 460 | 990 | 590 | 395 | 1770 | C250/460 | F3/8 |

| 500 | 20″ | 114 | 650 | 190 | 560 | 1020 | 680 | 425 | 1960 | C300/510 | F3/8 |

| 600 | 24″ | 114 | 760 | 230 | 620 | 1200 | 780 | 425 | 2275 | C300/610 | F3/8 |

Need a specific dimension sheet? Let us know your size and pressure class.

Applications That Require High Reliability

This bonneted knife gate valve is trusted in industries where failure is not an option. Use it when your media is abrasive, corrosive, or under extreme pressure/temperature. Common applications include:

- Mining and Minerals – Slurry, tailings, and concentrate lines

- Pulp and Paper – High-fiber content flows and dewatering systems

- Wastewater Treatment – Primary sludge, grit, and scum lines

- Chemical Plants – Acidic and alkaline solution isolation

- Power Generation – Fly ash and FGD slurry management

- Oil & Gas – Drilling mud, produced water, and fracking fluid control

FAQ

What’s the difference between a bonneted and bonnetless knife gate valve?

A bonneted valve features a sealed enclosure around the stem and packing, providing superior sealing and protection in high-risk environments.

Can I use this valve in a bidirectional flow system?

Yes, this valve is designed for bidirectional shutoff, making it ideal for flexible flow systems.

Do you offer custom materials or coatings?

Absolutely. We provide material upgrades including Hastelloy, Inconel, and epoxy coatings based on your process needs.

What documents do you provide with the valve?

You’ll receive a technical datasheet, dimensional drawing, installation manual, and material test certificate. 3D models are available upon request.

Is this valve suitable for automated operation?

Yes, you can choose from electric, pneumatic, or hydraulic actuators, depending on your control system.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.