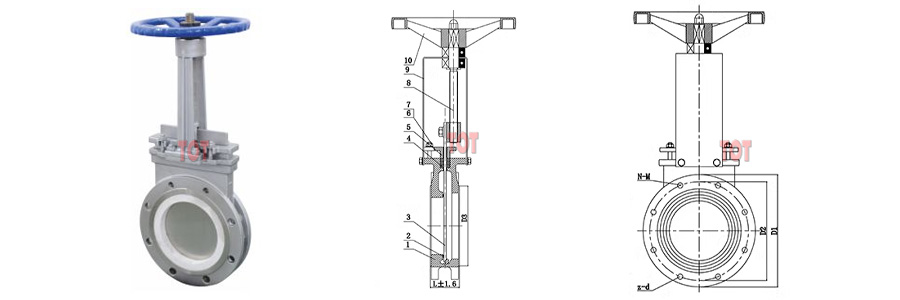

Flange Ceramic Knife Gate Valve

The flange ceramic knife gate valve of TOT Valve adopts hard seal for sealing surface, and the parts in contact with the medium are made of structural ceramic materials with good chemical stability and high hardness.

When you need to open and close pipelines containing high-hardness particles or soft particles but corrosive media, our ceramic knife gate valve is your ideal choice because it has strong wear resistance and corrosion resistance.

Contact us now to get the best ex-factory price.

Description

The flange ceramic knife gate valve produced by TOT Valve is made of high-quality WCB and stainless steel materials for casting or forging of valve body, gate and other main components, and the valve seat sealing surface is made of advanced structural ceramics such as aluminum oxide (Al₂O₃), zirconium oxide (ZrO₂).

Most customers choose ceramic knife gate valves mainly for slag conveying systems, which do not need to achieve zero leakage level. But if you need a zero leakage valve, we can change the valve seat material on one side from ceramic to polyurethane (PU), which can not only make your pipeline system reach zero leakage level, but also has excellent wear resistance.

Flange Ceramic Knife Gate Valve Features

- The sealing surface is made of structural ceramics, which is wear-resistant and has a long service life

- The valve seat adopts a single valve seat design to prevent adhesion and dust accumulation

- The ceramic knife gate valve has the characteristics of self-cleaning sealing surface

- Short end face size, easy installation, easy maintenance, etc.

- Widely used: ash, slag, coal slag in steel mills or ash conveying systems in power plants, pulp in the papermaking industry, sewage and slurry in purification plants, especially suitable for heavy medium systems of coal mills.

Main Performance Specification

| Nominal Pressure (Mpa) | Body Testing (Mpa) | Working Temperature (℃) | Appropriate Media |

|---|---|---|---|

| 1.0, 1.6 | 10.3 | ≦425℃ | Paper Pulp, Dirty Water, Coal Slurry, Ashes, Compounds of Water and Slag |

Materials of Main Pads

| Body, Cover | Gate | Stem | Seal Surface |

|---|---|---|---|

| Stainless Steel, Carbon Steel, + TC | Stainless Steel+TC | Stainless Steel | Ceramic |

Nominal Diameters and Coupling Sizes

| Nominal Pressure 1.0 MPa | |||||||

|---|---|---|---|---|---|---|---|

| DN | L | D | K | d | H | N-M | D0 |

| 50 | 48 | 160 | 125 | 100 | 310 | 4–M16 | 180 |

| 65 | 48 | 180 | 145 | 120 | 340 | 4–M16 | 180 |

| 80 | 48 | 195 | 160 | 135 | 380 | 8–M16 | 220 |

| 100 | 50 | 215 | 180 | 160 | 450 | 8–M16 | 220 |

| 125 | 50 | 245 | 210 | 180 | 480 | 8–M16 | 240 |

| 150 | 70 | 280 | 240 | 200 | 520 | 8–M20 | 240 |

| 200 | 70 | 335 | 295 | 250 | 580 | 8–M20 | 280 |

| 250 | 70 | 390 | 350 | 320 | 680 | 12–M20 | 320 |

| 300 | 70 | 440 | 400 | 370 | 720 | 12–M20 | 320 |

| 350 | 76 | 500 | 460 | 430 | 820 | 16–M20 | 350 |

| 400 | 89 | 565 | 515 | 480 | 980 | 16–M22 | 500 |

| 450 | 114 | 615 | 565 | 532 | 1150 | 20–M22 | 500 |

| 600 | 140 | 780 | 725 | 625 | 1800 | 20–M27 | 700 |

| 800 | 160 | 1020 | 950 | 898 | 2100 | 24–M30 | 700 |

| Nominal Pressure 1.6 MPa | |||||||

|---|---|---|---|---|---|---|---|

| DN | L | D | K | d | H | N-M | D0 |

| 50 | 48 | 160 | 125 | 100 | 310 | 4–M16 | 180 |

| 65 | 48 | 180 | 145 | 120 | 340 | 4–M16 | 180 |

| 80 | 48 | 195 | 160 | 135 | 380 | 8–M16 | 220 |

| 100 | 50 | 215 | 180 | 160 | 450 | 8–M16 | 220 |

| 125 | 50 | 245 | 210 | 180 | 480 | 8–M16 | 240 |

| 150 | 70 | 280 | 240 | 200 | 520 | 8–M20 | 240 |

| 200 | 70 | 335 | 295 | 250 | 580 | 12–M20 | 280 |

| 250 | 70 | 405 | 355 | 320 | 680 | 12–M22 | 320 |

| 300 | 70 | 460 | 410 | 370 | 720 | 12–M22 | 320 |

| 350 | 76 | 520 | 470 | 430 | 820 | 16–M22 | 350 |

| 400 | 89 | 580 | 525 | 480 | 980 | 16–M27 | 500 |

| 450 | 114 | 640 | 585 | 532 | 1150 | 20–M27 | 500 |

| 600 | 140 | 815 | 740 | 625 | 1800 | 20–M30 | 700 |

| 800 | 160 | 1020 | 950 | 898 | 2100 | 24–M36 | 700 |

* We are not just providing simple quotes but experts in selection, calculation, and drawing.