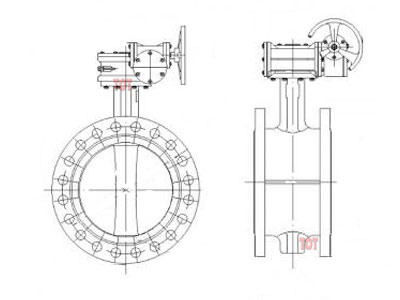

Fluorine Lined Butterfly Valve

TOT Fluorine lined butterfly valve adopts the central line fluorine lined structure,the valve body and disc are lined with anti-corrosive materials so as to effectively avoid the corrosion of the valve by strong corrosive media,so the valve has both the common butterfly valve mechanical strength, and also can play strong resistance to chemical medium properties .

When your process involves aggressive chemicals or ultra-pure media, you need more than just a standard valve. You need a solution that performs consistently, seals perfectly, and stands the test of time.

With TOT’s fully fluorine-lined butterfly valve, you get exactly that—plus a lot more. Contact us now to get the most competitive price.

Designed with Your Application in Mind

The fluorine-lined butterfly valve can be closed by rotating 90 degrees clockwise, without sticking, and the elastic valve seat design can achieve zero leakage. The valve adopts a torque valve seat, which is designed so that the valve disc can be rotated out of the valve seat without an actuator. No matter how your fluid flows, this fluorine-lined butterfly valve can achieve perfect shutoff.

You’re operating in an environment where chemical compatibility, zero leakage, and process safety are non-negotiable. That’s why this valve is built with a full 360° fluoropolymer liner—resistant to nearly all known corrosive compounds. Whether you’re handling hydrochloric acid, nitric acid, acetic acid, steam, or organic solvents, this valve ensures long-term durability and sealing integrity.

A resilient backup liner combined with a torque-seated disc ensures bubble-tight shut-off in both flow directions—no matter how tough the media or conditions.

The best part? The design eliminates the need for regular maintenance thanks to its long-life sleeve bearings and non-adjustable, leak-free sealing components.

What You Get — Key Performance Advantages

- Superior Corrosion Resistance: The internal flow path is fully lined with high-performance fluoropolymers like PTFE, PFA, FEP, or EPDM offering unmatched resistance to chemical attack. Ideal for toxic, reactive, or high-purity media.

- Zero Leakage Guarantee: Achieve zero leakage in both directions. The valve’s non-jamming, resilient-seated disc design ensures complete shut-off regardless of pressure or flow direction. Each valve is pressure-tested for sealing integrity before delivery.

- No Routine Maintenance Required: Thanks to the use of high-durability sleeve bearings and a seal design that avoids packing glands, you’ll experience less downtime, fewer manual checks, and a lower total cost of ownership.

- Multi-Standard Compatibility: Whether your system follows ANSI, DIN, ISO, or API standards, this valve integrates seamlessly into your piping with optional ISO 5211 actuator flanges and compliant face-to-face dimensions (ISO 5752, BS 5155, ASME B16.10, etc.).

- Smart Automation Ready: Easily automate the valve with electric, pneumatic, hydraulic, or electro-hydraulic actuators. Manual operation with lockable lever or gear operator is also available.

Detailed Specifications

| Parameter | Value / Options |

| Size Range | 2″ to 24″ (DN50–DN600); larger sizes available upon request |

| Body Materials | WCB, CF8, CF8M, CF3M, Duplex Steel |

| Lining Materials | PTFE, FEP, PFA, EPDM (FDA-compliant, non-contaminating) |

| Connection Types | Wafer, Lugged, Double Flanged |

| Temperature Range | -20°C to +150°C |

| Pressure Ratings | ANSI Class 150#, PN10, PN16 |

| Standards Compliance | ISO 5752, BS 5155, API 609, MSS-SP-68, ASME B16.10, ASME B16.5, DIN 3202 |

| Flow Control | Optional valve positioner enables equal percentage flow characteristics |

| Installation | Bi-directional flow; installable in any orientation |

| Operation Options | Manual Operation, Electric Actuation, Pneumatic Actuation, Hydraulic & Electro-Hydraulic Actuation |

Typical Applications

You can confidently apply this valve across a wide range of industries and processes:

- Chemical Processing Plants – for controlling acids, alkalis, oxidants, and solvents

- Petrochemical Facilities – for process isolation and flow control

- Pharmaceutical Production – FDA-compliant materials for ultra-pure systems

- Water Treatment Plants – resistant to disinfectants and chemical additives

- Pulp & Paper Industry – handles semi-fluid and corrosive pulp slurries

- Food & Beverage – non-toxic, corrosion-resistant construction for CIP/SIP systems

It serves perfectly as both an on/off valve and a flow regulating device, giving you full flexibility depending on your needs.

Let TOT Valve Support Your Process

Backed by stringent quality control, extensive field testing, and years of industry expertise, TOT’s fluorine-lined butterfly valve is not just a component—it’s a long-term asset to your operation.

Whether you’re upgrading a chemical line or specifying components for a new plant, this valve delivers the safety, efficiency, and flexibility you need.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.