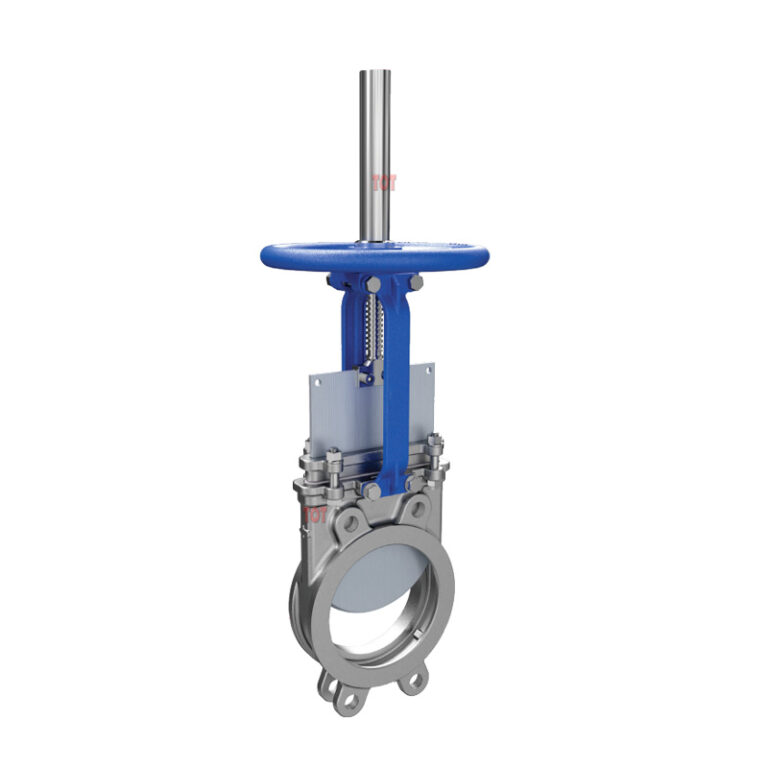

High Temperature Knife Gate Valve

When your operations demand absolute sealing performance and reliability under extreme heat, you need more than just an ordinary valve. You need a solution designed for resilience, precision, and long service life. Our High Temperature Knife Gate Valve is engineered to withstand severe service conditions in applications such as pulp & paper, power generation, mining, and chemical processing—where standard valves simply can’t keep up.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

This high-performance knife gate valve is specially developed to handle high-temperature media including steam, slurry, ash, or high-viscosity fluids. Designed to operate reliably at temperatures up to 550°C (1022°F), it features a robust one-piece body construction with heavy-duty seats and a sharpened gate that cuts through solids and semi-solids with ease.

Whether you’re specifying a valve for a new build or replacing an underperforming unit in your current line, this valve delivers superior flow control, tight shutoff, and long-term durability even in the harshest conditions.

Get a quote now! TOT Valve As a professional and reliable knife gate valve manufacturer, can definitely find the gate valve suitable for your application in the shortest time.

High Temperature Knife Gate Valve Main Technical Parameters & Performance Features

- Size Range: 2″ – 24″ (DN50 – DN600)

- Pressure Rating: Class 150 / PN10 / PN16

- Temperature Range: -50°C to +550°C (-58°F to +1022°F)

- Leakage Rate: Zero leakage to MSS-SP-81

- Testing Standards: API 598, ANSI B16.34

- Face-to-Face: MSS-SP-81 or customized

- Wafer or Lug body style: For flexible pipeline integration

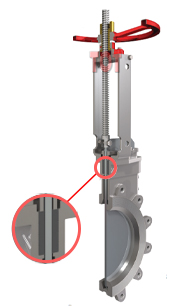

- Full bore design: Minimizes pressure drop, rising or non-rising stem options

- Various actuation types: Manual handwheel, pneumatic cylinder, or electric actuator

- Easy maintenance: Replaceable seats, packing, and gate

- Bidirectional shutoff (optional) to suit flow direction changes

Main Components and Materials

| Component | Standard Material Options |

| Body | Stainless Steel, Cast Steel, Alloy Steel |

| Gate | 304 / 316 Stainless Steel, Monel, Hastelloy |

| Seat | Metal Seat or High-Temp Soft Seal (Graphite, PTFE+SS) |

| Stem | 304 SS, 316 SS |

| Packing | Graphite, PTFE |

| Gland | Stainless Steel |

| Yoke | Carbon Steel or Stainless Steel |

| Actuator | Manual, Pneumatic, Electric (explosion-proof optional) |

*TOT Valve Can provide customized materials according to your application environment, such as corrosive or abrasive application requirements.

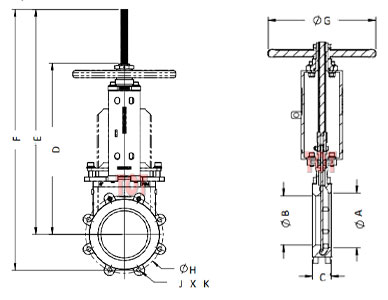

High Temperature Knife Gate Valve Dimensions

| Dimensions | ΦA | ΦB | C | D | E | F | ΦG | ΦH | J | K | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | In | ||||||||||

| 80 | 3 | 3 | 2.7 | 2 | 14.13 | 17.38 | 20.13 | 9.75 | 6 | 4 | 5/8″-11 |

| 100 | 4 | 4 | 3.6 | 2 | 16.25 | 20.5 | 24.5 | 9.75 | 7.5 | 8 | 5/8″-11 |

| 150 | 6 | 6 | 5.4 | 2.25 | 19.5 | 25.75 | 30.75 | 9.75 | 9.5 | 8 | 3/4″-10 |

| 200 | 8 | 8 | 7.2 | 2.75 | 26 | 34.13 | 40.5 | 15.75 | 11.75 | 8 | 3/4″-10 |

| 250 | 10 | 10 | 9 | 2.75 | 30.5 | 40.38 | 48 | 15.75 | 11.75 | 12 | 7/8″-9 |

| 300 | 12 | 12 | 10.8 | 3 | 37.25 | 47.5 | 56.5 | 15.75 | 17 | 12 | 7/8″-9 |

| 350 | 14 | 14 | 13.8 | 3 | 39.84 | 53.07 | 48.22 | 15.75 | 18.75 | 16 | 1″-8 |

| 400 | 16 | 16 | 14.81 | 3.5 | 44.6 | 59.92 | 54.11 | 19.69 | 21.25 | 16 | 1″-8 |

| 450 | 18 | 18 | 16.46 | 3.5 | 48.03 | 65.39 | 58.53 | 19.69 | 22.75 | 16 | 1 1/8″-7 |

| 500 | 20 | 20 | 18.35 | 4.5 | 52.28 | 71.69 | 63.78 | 23.62 | 25 | 20 | 1 1/8″-7 |

| 600 | 24 | 24 | 22 | 4.5 | 59.92 | 83.34 | 73.55 | 23.62 | 29.5 | 20 | 1 1/8″-7 |

*Dimensions vary based on actuation type and flange standard. Contact us for CAD drawings or 3D models.

Applications That Require High Reliability

You’ll benefit from our High Temperature Knife Gate Valve in applications where flow media are hot, abrasive, or viscous, and where failure is not an option:

- Pulp & Paper Mills: For black liquor, pulp slurry, and stock lines

- Thermal Power Plants: Fly ash, bottom ash, and boiler feed systems

- Chemical Processing: Aggressive fluids under high pressure and temperature

- Mining & Ore Handling: Tailings, slurry, and thickened concentrates

- Steel Mills: Blast furnace exhaust and hot water pipelines

- Wastewater Treatment: High-temperature sludge and grit removal

Choose a knife gate valve built for extremes, so your process never has to slow down. Have a spec or need a recommendation? Get in touch with our TOT Valve Team for a fast quote or customized solution.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.