Manual V-Port Ball Valve

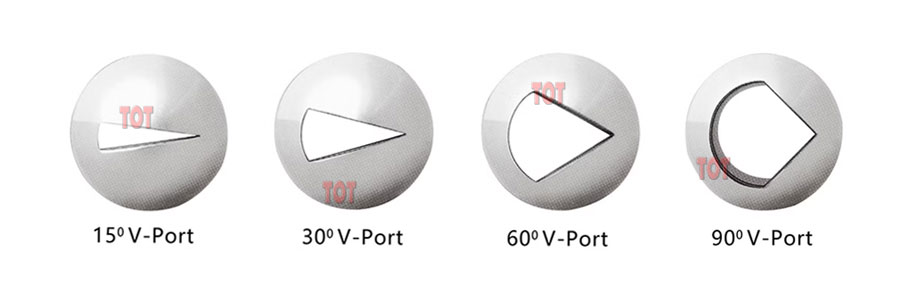

If you need accurate and consistent flow control, a V-port ball valve is built for the job. Unlike standard ball valves, this valve uses a v-shaped ball or seat that opens gradually—giving you linear flow characteristics rather than sudden on/off flow. You can choose from various “V” angles depending on how finely you need to regulate the flow.

As a professional v-port ball valve manufacturers and suppliers, TOT Valve can not only provide you with high-quality V-port valves, but also give you unparalleled factory prices. Contact us now to get more stable products for your fluid control system.

Description

If you’re searching for precise flow control, a V-port ball valve is the ideal solution. Unlike standard ball valves, this control valve features a v-shaped ball or seat that opens gradually, offering linear flow characteristics and reducing pressure surges.

You can choose from different v port profiles—such as 15°, 30°, 45°, 60°, and 90°—to match your system’s specific requirements. That’s what makes v port ball control valves an essential part of many industrial automation and fluid control applications.

How a V-Port Valve Works?

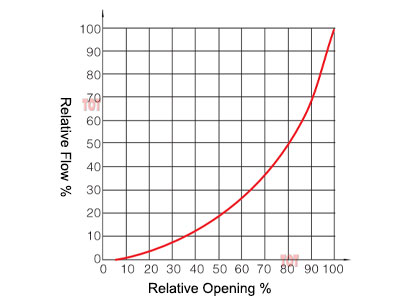

A V-port valve uses a precision-engineered ball with a V-shaped bore. As you turn the handle or engage an actuator, the bore aligns with your pipeline. The small end of the V opens first, allowing for smooth, incremental fluid flow. This mechanism enables you to control flow with a high degree of accuracy—ideal for demanding processes.

Whether you choose a manual V-port ball valve or an actuated one, all it takes is a quarter-turn to go from fully closed to fully open. This makes installation and operation fast, reliable, and efficient.

How to Choose the Right V-Port Ball Valve?

- Precise Flow Control: Our v port ball valves offer equal-percentage flow characteristics, allowing for smooth, accurate regulation. Perfect for throttling, dosing, or modulating applications.

- Low Pressure Drop: The valve’s straight-through flow path reduces turbulence and minimizes pressure loss. You can even downsize without compromising flow rate.

- High Shut-Off Capability: Thanks to the quarter-turn design, our manual v port ball valves operate reliably even at high pressures—requiring only a compact actuator.

- Bubble-Tight Shut-Off: The floating ball seats tightly against pressure, delivering leak-free (bubble-tight) performance—ideal for gas and critical containment systems.

Design Standards

TOT Valve provides different types of V-port ball valves that comply with ISO and ASME standards.

| Pressure & Temperature | Structural Length | Temperature Range | Sealing & Strength Test Standards |

|---|---|---|---|

| ASME B16.34-2003, ISO 7005-1 | ISA S75.04-1995, IEC/DIN 534-3-2 | -46℃ ~ 343℃ | GB/T 4213-2007 |

Manual V-Port Ball Valve Main Components and Materials

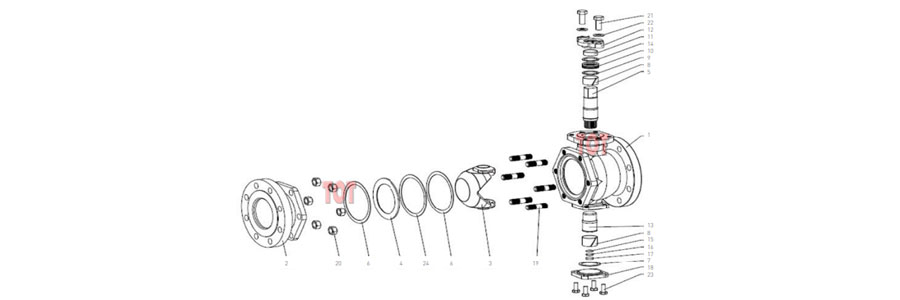

The TOT V-port ball valve is well-made and easy to operate and clean. It consists of a durable stainless steel metal body, self-lubricating bearings, a low-friction shaft and a manual V-port ball. In addition, a variety of seat options are available, such as metal seats or soft seats. Below is a summary of the main components of the V-port ball valve and their component materials for you to choose from.

Valve Stem: The valve stem is finely ground and matched with the actuator with high precision, making the valve backlash small

Valve Body: The valve body adopts an integral structure with good rigidity, reducing the possibility of leakage

Packing: The packing is made of high-quality PTFE material with good sealing

Bearing: The bearing adopts self-lubricating bearing with high load-bearing capacity, small friction coefficient, and reduced operating torque

Spring: The spring adopts a special hexagonal spring, which reduces the friction between the ball and the valve seat while providing preload, making the valve operating torque smaller

Ball: The ball with a V-notch is hard chrome plated, ion nitrided or supersonic sprayed on the spherical surface to improve the surface hardness, so that the ball mouth has a hard and sharp edge with shearing function for the medium

Valve Seat: The special bonnetless design makes there is no dead angle between the valve seat and the valve body, the medium is not easy to accumulate, and the solid particle medium will not be stuck

| No. | Name | Material | ||

|---|---|---|---|---|

| 1 | Body | WCB | CF8 | CF8M |

| 2 | Core | CF8 surface hard nickel plating | CF8 surface hard nickel plating | CF8M surface hard nickel plating |

| 3 | Cylindrical Pin | 304 | 304 | 316 |

| 4 | Seat | 304 cladding carbide | 304 cladding carbide | 316 cladding carbide |

| 5 | Spring | 316 | 316 | 316 |

| 6 | O-ring | Fluororubber | Fluororubber | Fluororubber |

| 7 | Self-lubricating bearing | 304+PTFE | 304+PTFE | 316+PTFE |

| 8 | Lower Valve Stem | 20Cr13 | 304 | 316 |

| 9 | O-ring | Fluororubber | Fluororubber | Fluororubber |

| 10 | Rear Gland | WCB | CF8 | CF8M |

| 11 | Ring Washer | PTFE | PTFE | PTFE |

| 12 | Adjusting Washer | PTFE | PTFE | PTFE |

| 13 | Flat Washer | Q235 | 304 | 304 |

| 14 | Bolt | 25 | 304 | 304 |

| 15 | Stud | 25 | 304 | 304 |

| 16 | Self-lubricating bearing | 304+PTFE | 304+PTFE | 316+PTFE |

| 17 | Flat key | 20Cr13 | 304 | 316 |

| 18 | Lower Packing | PTFE | PTFE | PTFE |

| 19 | Middle Packing | PTFE | PTFE | PTFE |

| 20 | Upper Packing | PTFE | PTFE | PTFE |

| 21 | Package Gland | WCB | CF8 | CF8M |

| 22 | Nut | 35 | 304 | 304 |

| 23 | Upper Valve Stem | 20Cr13 | 304 | 316 |

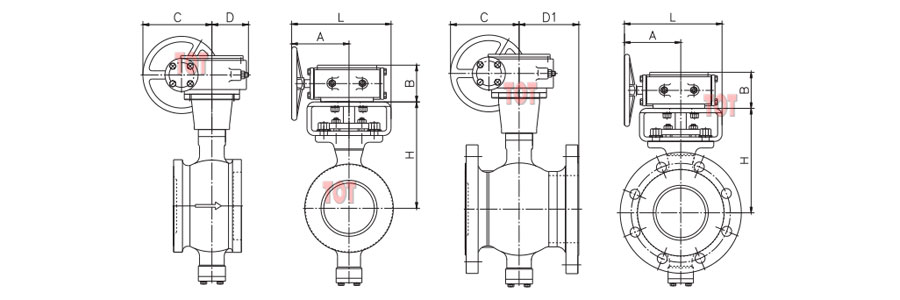

Manual V-Port Ball Valve Overall Dimensions

TOT Valves can provide you with various sizes of manual V-port ball valves. We have listed some manual V-port ball valve sizes suitable for PN16/150LB for your reference.

If you do not have the manual V-port ball valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A | L | B | H | C | D | D1 | |

|---|---|---|---|---|---|---|---|---|

| DN | Inch | |||||||

| 25 | 1″ | 145 | 200 | 70 | 133 | 170 | 60 | 60 |

| 32 | 1-1/4″ | 145 | 200 | 70 | 138 | 170 | 60 | 60 |

| 40 | 1-1/2″ | 145 | 200 | 70 | 140 | 170 | 60 | 60 |

| 50 | 2″ | 145 | 200 | 70 | 150 | 170 | 60 | 64 |

| 65 | 2-1/2″ | 145 | 200 | 70 | 165 | 170 | 60 | 75 |

| 80 | 3″ | 145 | 200 | 70 | 178 | 170 | 60 | 90 |

| 100 | 4″ | 145 | 200 | 70 | 190 | 170 | 60 | 100 |

| 125 | 5″ | 170 | 235 | 74 | 205 | 190 | 75 | 97 |

| 150 | 6″ | 170 | 235 | 74 | 235 | 190 | 75 | 120 |

| 200 | 8″ | 190 | 265 | 90 | 265 | 220 | 83 | 125 |

| 250 | 10″ | 215 | 325 | 100 | 317 | 270 | 106 | 150 |

| 300 | 12″ | 215 | 325 | 100 | 362 | 270 | 150 | 150 |

| 350 | 14″ | 260 | 370 | 125 | 437 | 300 | 180 | 180 |

| 400 | 16″ | 260 | 370 | 125 | 492 | 300 | 180 | 180 |

| 450 | 18″ | 260 | 370 | 125 | 570 | 300 | 230 | 230 |

| 500 | 20″ | 270 | 415 | 130 | 640 | 340 | 280 | 280 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.