PTFE Lined Rubber Expansion Joint

Chemical-Resistant Flexibility for Demanding Pipeline Applications

When you’re dealing with corrosive media, temperature fluctuations, and mechanical vibration, you need more than just flexibility—you need chemical confidence. Our PTFE lined rubber expansion joints offer unmatched resistance to aggressive fluids while maintaining structural flexibility under pressure.

Request a Quote Today! Let’s build the perfect expansion joint for your system.

Description

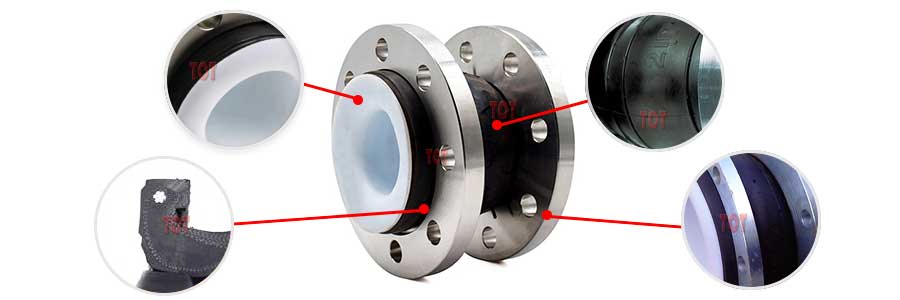

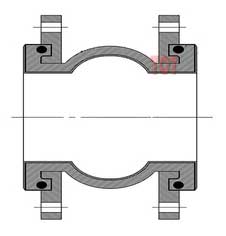

The PTFE lined rubber expansion joint, also called teflon lined rubaber joint, fluoroplastic-lined joint, or chemical resistant rubber bellow, is a PTFE lined flexible connector that provides reliable performance in harsh environments.

The expansion joint we offer combines the flexibility of rubber with the excellent chemical resistance of PTFE (polytetrafluoroethylene), and is designed for your pipelines that convey corrosive fluids such as strong acids and alkalis. Widely used in industrial pipeline applications such as food grade systems, high purity water, petroleum, chemical, pharmaceutical, etc.

TOT’s polytetrafluoroethylene lined rubber joints are reinforced with steel wire layers and standard flanges (ANSI, DIN, JIS) to prevent leaks, withstand pressure, and absorb vibration and thermal displacement.

TOT Valve As a professional expansion joint manufacturer and supplier, can provide you with a variety of different types and sizes of PTFE lined expansion joints, and can also provide customized services according to your special needs.

Contact us now, our PTFE lined expansion joints are your ideal solution for long-term corrosion protection and pipeline flexibility.

PTFE Lined Expansion Joint Key Features

PTFE Lined Interior: Provides complete resistance to acids, alkalis, and solvents

Flexible Rubber Body: Absorbs thermal expansion and mechanical vibration

Wide Media Compatibility: Perfect for aggressive chemical, pharmaceutical, and food applications

Anti-Adhesion Surface: Prevents media buildup and ensures easy cleaning, non-toxic, anti-aging, and temperature resistant

Customizable Ends: Available in flanged, or special end connections

Temperature & Pressure Resilience: Handles up to 200°C and 16 bar (model-dependent)

Noise & Vibration Damping: Protects pumps, valves, and connected equipment

Standards: Flanged ends available in ANSI, DIN, and JIS standards

Main Components and Materials

| Component | Material |

|---|---|

| Lining | Pure PTFE (Teflon) |

| Outer Rubber | EPDM / NBR / Neoprene |

| Reinforcement | Nylon cord / Steel wire |

| Flanges (optional) | Carbon steel / Stainless steel |

| Retaining Rings | Galvanized steel or stainless |

PTFE Lined Joint Specifications & Dimensions

| DN | Inch | Length (L) mm | Flange Thickness (b) mm | Axial Extension mm | Lateral Displacement mm | Angular Deflection (°) |

|---|---|---|---|---|---|---|

| DN32 | 1-1/4″ | 95 | 16 | 6 | 9 | 9 |

| DN40 | 1-1/2″ | 95 | 18 | 6 | 10 | 9 |

| DN50 | 2″ | 105 | 18 | 7 | 10 | 10 |

| DN65 | 2-1/2″ | 115 | 20 | 7 | 13 | 11 |

| DN80 | 3″ | 135 | 20 | 8 | 15 | 12 |

| DN100 | 4″ | 150 | 22 | 10 | 19 | 13 |

| DN125 | 5″ | 165 | 22 | 12 | 19 | 13 |

| DN150 | 6″ | 180 | 24 | 12 | 20 | 14 |

| DN200 | 8″ | 210 | 24 | 16 | 25 | 22 |

| DN250 | 10″ | 230 | 26 | 16 | 25 | 22 |

| DN300 | 12″ | 245 | 28 | 16 | 25 | 22 |

| DN350 | 14″ | 255 | 28 | 16 | 25 | 22 |

| DN400 | 16″ | 255 | 30 | 16 | 25 | 22 |

| DN450 | 18″ | 255 | 30 | 16 | 25 | 22 |

| DN500 | 20″ | 255 | 32 | 16 | 25 | 22 |

*Custom sizes and movement ranges are available upon request.

Applications That Require High Reliability

This expansion joint is purpose-built for industries and applications where aggressive media and demanding mechanical conditions are part of daily operations:

- Chemical Process Lines – Handles sulfuric acid, hydrochloric acid, caustic soda, and more

- Pharmaceutical Production – Clean, non-contaminating, easy to maintain

- Water & Wastewater Treatment – Resistant to chlorine, ozone, and chemicals

- Power Generation Systems – Compensates for heat and vibration near pumps and condensers

- Desalination & Marine Systems – Salt and chemical resistance without corrosion

- Oil & Gas Refineries – Performs under variable temperatures and harsh conditions

- Food & Beverage Facilities – PTFE purity is ideal for hygienic process piping

The result? A durable, vibration-absorbing, acid-proof solution that protects your piping system from both chemical attack and mechanical stress. Whether your system carries sulfuric acid, sodium hydroxide, or solvent-rich media, you can count on this expansion joint to maintain performance and purity—day in and day out. Contact Us Today! → →

FAQ

What’s the difference between PTFE lined and standard rubber expansion joints?

PTFE lined joints are designed for harsh chemical environments. The PTFE lining offers chemical inertness, unlike standard rubber, which may degrade over time when exposed to acids or solvents.

Can this joint handle steam or high-temperature media?

Yes. With the correct rubber body (e.g., EPDM or Neoprene) and a PTFE lining, it can handle media up to 200°C. Please confirm media compatibility before use.

Is it possible to customize the flange type and overall length?

Absolutely. We offer a wide range of customization options, including flange drilling standards (ANSI, DIN, JIS), face-to-face length, and lining thickness based on your system needs.

What are the maintenance requirements?

Thanks to the anti-stick PTFE lining and durable rubber construction, these joints are generally maintenance-free. Periodic visual inspection is sufficient under normal service conditions.

How long does a PTFE lined rubber expansion joint last?

When properly installed and used within design limits, service life can exceed 10 years in many industrial applications.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.