Semi Lug Knife Gate Valve

When you need reliable isolation in challenging flow conditions, a standard valve just won’t do. This stainless steel semi lug knife gate valve is designed for your most demanding applications — whether you’re handling slurry, pulp, or corrosive fluids. The semi-lug body lets you isolate either side of the pipeline safely, even under full pressure, reducing downtime during maintenance or system upgrades. TOT Valve with corrosion-resistant stainless steel materials and flexible actuation options, it gives you long-term performance in industries where safety, efficiency, and durability matter most.

Ready to upgrade your flow control system? Get in touch today for a customized solution that fits your exact specifications. Let TOT Valve support your business.

The TOT Valve You Can Depend On – Even in the Most Demanding Conditions

When your process involves slurry, pulp, abrasive fluids, or corrosive chemicals, you can’t afford valve failure. TOT Valve With its semi-lugged stainless steel body, this knife gate valve is designed to give your system absolute shut-off, dead-end service compatibility, and rigid flange mounting — without compromise.

With its lugged body, you can safely install it at the end of your pipeline and easily remove one side without disrupting the other — perfect for systems that require frequent maintenance or isolation.

Why Lug Type Knife Gate Valve Works for You?

- Corrosion-resistant stainless steel (SS304/316) keeps your operation running in aggressive environments.

- Lug-style design lets you isolate lines or use it in dead-end service without extra support.

- Knife-edge gate slices through thick media like pulp, slurry, or powders with no clogging.

- Soft or metal seats ensure you get the shut-off performance your application demands.

- Choose your actuator – manual, pneumatic, electric, or chainwheel – for total control.

- Low maintenance – reduce downtime with replaceable seats and packing.

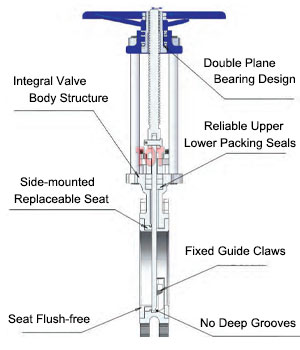

- Double plane bearing design, transmission friction is reduced, valve opening is smooth.

- No deep groove at the bottom of the valve body will not cause medium accumulation and jamming.

- Integral valve body structure is easy to install, flow resistance is small.

Lug Knife Gate Valve Main Technical Specifications & Performance

| Single-direction Sealing, Resilient Seat, One-piece Semi Lug Knife Gate Valve | |

|---|---|

| Design & Manufacturing Standard | MSS SP-81 |

| Size Range | DN50 to DN1200 mm; NPS 2″-48″ (Customized to Your Request) |

| Pressure Ratings | PN10, PN16, ANSI 150Psi, 5K/10K, etc. |

| Working Pressure Classification | DN50–DN250: 10Bar; DN300–DN450: 7Bar; DN500–DN600: 4Bar; DN700–DN1200: 2Bar |

| Face-to-Face Standard | MSS SP-81 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Inspection & Testing Standard | MSS SP-81 |

| Body Materials | GGG40, WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature–Pressure Rating Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Applications | Pulp & Paper, Mining, Chemical, Pharmaceutical, Potable Water, Wastewater Treatment, Municipal Sewage, Water Conservancy, etc. |

| Actuation Methods | Manual, Pneumatic, Electric, Gear Drive, Chain Drive, Lever |

Lug Knife Gate Valve Main Components and Materials

| Part Name | Material | ||

|---|---|---|---|

| Body | WCB | CF8 | CF8M |

| Gate | 304 | 316 | |

| Seat | STL or EPDM | ||

| O-ring | NBR | ||

| Gland Flange | WCB | CF8 | CF8M |

| Packing | PTFE | ||

| Yoke Cover | WCB | CF8 | CF8M |

| Yoke | Q235 | 304 | |

| Stem | 2Cr13 | ||

| Stem Nut | Brass | ||

| Pin | 65Mn | ||

| Support | WCB | ||

| Handwheel | GGG30 | ||

| Stem Protector | 304 | ||

| Fasteners | A2-70 | ||

TOT Valve Tailored for Your System – Custom Options

You can customize this valve for your exact system requirements:

- Gate Finish: Polished, hardened edge, or duplex stainless

- Seat Type: EPDM, PTFE, Viton, metal seated with Stellite overlay

- Actuation Options: Pneumatic actuator with solenoid & limit switch, electric motor with controls

- Body Coating: Epoxy, ceramic lining, PFA lining for enhanced chemical resistance

- Automation Ready: ISO 5211 mounting pad for easy actuator installation

Lug Knife Gate Valve Dimensions

TOT valve can provide you with various sizes of lug knife gate valve. We have listed some lug type knife gate valve sizes for PN16 for your reference.

If you don’t have the lug type knife gate valve size you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | |

|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(in) | ||||||||

| 50 | 2″ | 48 | 135 | 106 | 100 | 129 | 85 | 180 | 395 |

| 65 | 2-1/2″ | 48 | 155 | 106 | 115 | 147 | 85 | 180 | 436 |

| 80 | 3″ | 51 | 175 | 106 | 121 | 168 | 85 | 200 | 478 |

| 100 | 4″ | 51 | 163 | 106 | 138 | 192 | 85 | 200 | 545 |

| 125 | 5″ | 57 | 192 | 120 | 160 | 215 | 87 | 250 | 630 |

| 150 | 6″ | 57 | 216 | 130 | 185 | 245 | 87 | 280 | 705 |

| 200 | 8″ | 70 | 271 | 130 | 235 | 302 | 105 | 300 | 850 |

| 250 | 10″ | 70 | 335 | 140 | 300 | 355 | 105 | 350 | 1065 |

| 300 | 12″ | 76 | 381 | 160 | 350 | 401 | 105 | 400 | 1200 |

| 350 | 14″ | 76 | 436 | 180 | 400 | 465 | 117 | 450 | 1375 |

| 400 | 16″ | 89 | 505 | 180 | 455 | 511 | 117 | 450 | 1525 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.