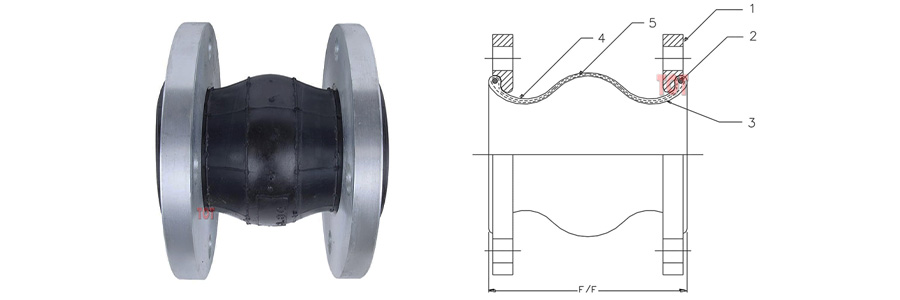

Single Sphere Rubber Expansion Joints

TOT stainless steel single sphere rubber expansion joints feature high-quality stainless steel flange ends at both ends and a molded nylon fabric reinforced neoprene body in the middle, making installation easy and simple for any application.

We stock a variety of sizes of single sphere rubber bodies and stainless steel flanges, and if your project requires one of our stainless steel single ball rubber expansion joints, we can also quickly turn around and shorten delivery time.

Contact us now for the best quote.

Applications

You can use TOT stainless steel single sphere rubber expansion joints not only for water supply and drainage equipment in piping systems, but also for refrigeration systems, blowers and air compressors in industrial plants.

Structural Design

- The outer layer protects the surface of the bellows from ozone erosion and impact, which will reduce the service life.

- Spherical design for improved efficiency.

- Easy to assemble: Both ends are equipped with flanges made of high-quality stainless steel, forged to accommodate full rubber.

- Allows connection at different angles: axial compression and tension, lateral and multi-angle deflection.

- Robust design, made of nylon braided fabric, which provides high shell molding resistance while having high burst pressure, and can absorb noise and vibration.

- Both ends are equipped with reinforcement wires, and high-quality low-carbon steel strands provide greater consistency for the outer neck of the tube.

- Light weight, easy installation, small installation space required, replaceable bellows, easy maintenance.

- Full rubber design, self-sealing, no need for additional gaskets, can prevent electrolytic corrosion.

Materials

| Part Description | Flanges | Reinforcing Wire | Tube | Cover | Reinforcing Fabric |

| Material | Stainless Steel | Mild Steel Strands | Neoprene Rubber | Neoprene Rubber | Nylon Fiber |

Main External and Connection Dimension

| Size(in) | Face To Face Dimensions(in) | Allowable Motion Ratings(in) | Installation Tolerances(in) | ||||||

| Compression | Elongation | Lateral | Angular | Compression | Elongation | Lateral | Angular | ||

| 1 | 6 | 0.50 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 1-1/4 | 6 | 0.50 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 1-1/2 | 6 | 0.50 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 2 | 6 | 0.50 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 2-1/2 | 6 | 0.50 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 3 | 6 | 0.50 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 4 | 6 | 0.63 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 5 | 6 | 0.63 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 6 | 6 | 0.63 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 8 | 6 | 0.63 | 0.38 | 0.50 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 10 | 8 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 12 | 8 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 14 | 8 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 16 | 8 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 18 | 8 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 20 | 8 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

| 24 | 10 | 0.75 | 0.50 | 0.75 | 15 | 0.19 | 0.13 | 0.25 | 5 |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.