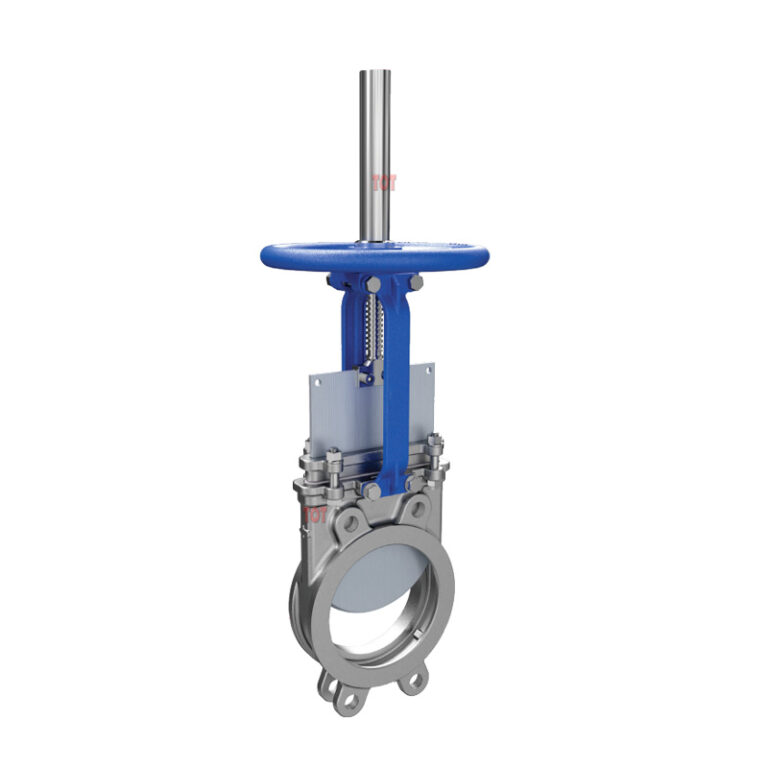

Slurry Knife Gate Valve

If you’re working with abrasive slurries, high solid concentrations, or scaling media, you know how crucial reliable flow isolation is. Our Slurry Knife Gate Valve is built to meet those demands—offering dependable shut-off, minimal maintenance, and extended service life, even in the harshest operating environments.

TOT Valve As a professional slurry knife gate valve manufacturers, can not only provide you with high-quality and durable products, but also provide you with market competitive prices.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

The Slurry Knife Gate Valve is purpose-built for handling slurry, pulp, and other high-density media that would quickly damage standard valves. With a full-bore, non-clogging design and bi-directional sealing, it provides smooth, unobstructed flow and absolute tightness under pressure.

Whether you’re operating in mining, power, pulp & paper, or wastewater treatment, this slurry knife gate valve gives you the performance and durability your system depends on.

Slurry Knife Gate Valve Features

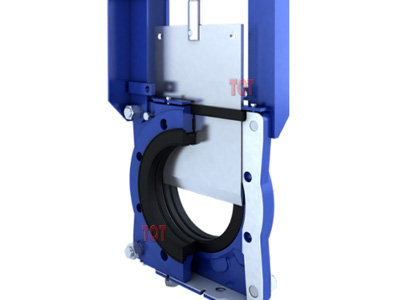

- Full-Port Flow – Reduces pressure loss and prevents clogging

- Bi-directional Sealing – Ensures tight shut-off in both directions

- Replaceable Sleeves – Increase wear resistance and reduce downtime

- Multiple Actuation Options – Manual, pneumatic, electric, or hydraulic

- Versatile End Connections – Wafer, lug, or flanged per your system

- Self-Cleaning Gate Design – Prevents media build-up and jamming

- Easy Maintenance – Modular structure with accessible internal parts

- Safe & Reliable – Leak-tight sealing in severe conditions, compatible with global standards and automation systems

- Proven Performance – Broad material availability for mining, pulp & paper, wastewater etc. corrosive or high-temp media

Main Technical Parameters & Performance

| Abrasion-Resistant Bi-Directional Soft Seal Knife Gate Valve (Rubber Seated, One-Piece or Two-Piece Body, Wafer Type) | |

|---|---|

| Size Range | DN50–DN600; NPS: 2″~24″ |

| Pressure Rating | PN10, PN16, ANSI 150Psi, 5K/10K |

| Working Pressure Classification | DN50–DN300: 10Bar DN350–DN450: 8Bar DN500–DN600: 6Bar |

| Flange Standards | GB/T9113-2010, EN1092-2002, ASME B16.5-2013, ASME B16.47-2011, AS2129-2000, AS4087-2004, JIS B2220-2004 |

| Valve Inspection & Testing Standard | MSS SP-81 (zero leakage under water pressure) |

| Body Materials | GGG40, WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature & Pressure Rating Standards | GB/T12224-2007, ASME B16.34-2009, ISO7005-1 |

| Applications | Mining, Chemical, Pharmaceutical, Water Supply, Wastewater Treatment, Municipal Drainage |

| Actuation Options | Manual, Pneumatic, Electric, Gear Drive, Chain Drive |

Need special materials for aggressive media? Just let us know—custom configurations are available.

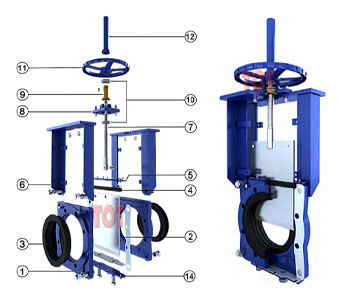

Main Components and Materials

| Part | Material | ||

|---|---|---|---|

| Body | GGG40 | CF8 | CF8M |

| Gate | 304 | 304 | 316 |

| Seat | NBR or EPDM | ||

| Packing | NBR | ||

| Packing Gland | #45 | CF8 | CF8M |

| Yoke | #45 | ||

| Stem | 2Cr13 | ||

| Stem Nut | Brass | ||

| Shaft | 65Mn | ||

| Seat Support | WCB | ||

| Handwheel | GGG30 | ||

| Stem Protector | 304 | ||

| Fasteners | A2–70 | A2–70 | A4–70 |

| Bonnet Cover | #45 | 304 | 316 |

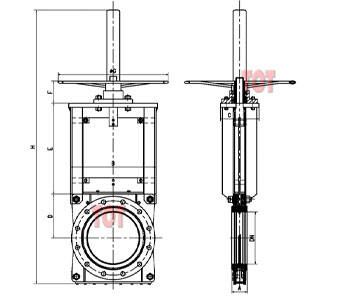

Slurry Knife Gate Valve Dimensions

TOT Valve Available in a wide range of sizes from 2″ up to 24″, the Slurry Knife Gate Valve is manufactured according to international flange and face-to-face standards.

You can refer to our dimension chart or drawing below to seamlessly integrate this slurry knife gate valve into your system application. You can also contact us today for more detailed dimensions and installation instructions.

| Size | A | B | C | D | E | F | G | H | |

|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | ||||||||

| 50 | 2″ | 60 | 180 | 150 | 105 | 145 | 85 | 200 | 490 |

| 80 | 3″ | 63 | 205 | 150 | 125 | 175 | 85 | 200 | 570 |

| 100 | 4″ | 63 | 245 | 150 | 130 | 200 | 87 | 280 | 625 |

| 150 | 6″ | 69 | 280 | 190 | 150 | 265 | 105 | 300 | 755 |

| 200 | 8″ | 83 | 345 | 200 | 180 | 325 | 105 | 350 | 935 |

| 250 | 10″ | 83 | 420 | 210 | 210 | 350 | 105 | 400 | 1090 |

| 300 | 12″ | 90 | 485 | 210 | 250 | 415 | 117 | 450 | 1260 |

| 350 | 14″ | 90 | 535 | 230 | 275 | 490 | 117 | 500 | 1410 |

Applications That Require High Reliability

This slurry knife gate valve is your go-to solution when the process demands absolute reliability, minimal leakage, and superior wear resistance:

- Mining & Mineral Processing – Tailings, slurry transport, ore concentrate

- Pulp & Paper Industry – Pulp stock, recycled fiber systems

- Wastewater Treatment – Sludge, grit removal, sediment handling

- Power Plants – Fly ash, bottom ash, slurry feed lines

- Chemical Plants – Corrosive or scaling media

- Dredging & Marine – Silt, sand, and abrasive slurry discharge

FAQ

What makes this Slurry Knife Gate Valve different from standard knife gate valves?

It’s built for abrasion resistance, includes replaceable sleeves, and offers bi-directional sealing—critical for slurry isolation applications.

Can I choose different body or seat materials?

Yes, you can fully customize the materials to match your process media, temperature, and pressure needs.

How often does it need to be maintained?

Compared to standard valves, maintenance frequency is lower due to the self-cleaning design and modular construction.

Is it compatible with automation systems?

Absolutely. We offer electric, pneumatic, and hydraulic actuators with control accessories.

TOT Valve offer documentation for engineering teams?

Yes. Technical datasheets, CAD models, installation manuals, and IOM guides are all available upon request.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.