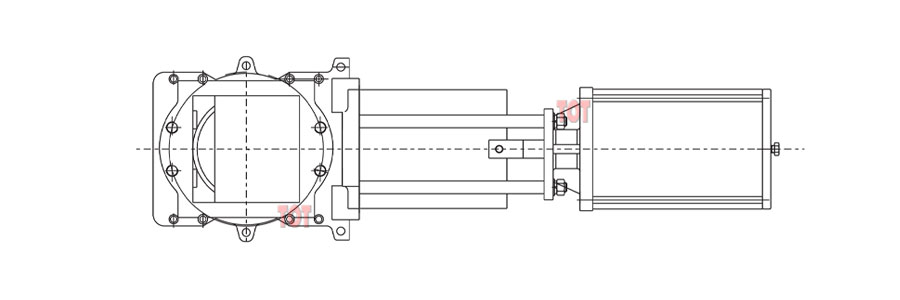

Square Port Knife Gate Valve

Efficient Flow Control with Square Discharge – Designed for Bulk Solids, Slurry, and Harsh Media

If you’re working in industries where material flow is critical — such as pulp and paper, mining, wastewater, or cement — your valve must handle dense, sticky, or abrasive media without clogging. Our Square Port Knife Gate Valve is specifically engineered to meet this demand.

Unlike traditional knife gate valves, this square knife gate valve features a round inlet for easy pipeline integration and a square or rectangular outlet that allows full-bore, unrestricted material discharge. It’s the valve you need when flow efficiency and reliability truly matter.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

The square port knife gate valve is a unidirectional, low-pressure gate valve designed for open discharge applications. Its square or rectangular outlet is intentionally larger than the round inlet, eliminating any narrowing or bottleneck at the exit point.

This design reduces the risk of material build-up, making it ideal for handling:

- Thick slurries

- Fibrous pulp

- Granular or powdered solids

- High-viscosity fluids

Whether installed under a silo, hopper, or in a process pipeline, this square gate valve ensures smooth shutoff, fast discharge, and low maintenance cycles.

Get a quote now and let us help you find the right square knife gate valve for your application in the shortest possible time.

Square Knife Gate Valve Features & Benefits

| Feature | What You Gain |

| Round Inlet + Square Outlet | Full-bore flow, zero clogging at discharge point |

| Oversized Discharge Port | Handles high-volume bulk media with ease |

| Active Seat Sealing | Reliable shut-off even in abrasive or sticky media |

| Two-Piece Body Design | Quick maintenance and internal inspection |

| Available Actuation Types | Pneumatic, electric, manual, chain wheel |

| Wide Compatibility | Works with ANSI, DIN, JIS, GB flanges |

Main Technical Parameters & Performance

| Unidirectional Knife Gate Valve with Round Inlet and Rectangular Outlet, Seat with Replaceable Insert, Two Half Body Design | |

|---|---|

| Design & Manufacturing Standard | MSS SP–81 |

| Size Range | DN100 ~ DN600; NPS: 4″-24″ |

| Pressure Ratings | PN10, PN16, ANSI 150Psi, 5K / 10K |

| Working Pressure by Size | DN100 ~ DN250: 10Bar, DN300 ~ DN450: 7Bar, DN500 ~ DN600: 4Bar |

| Face-to-Face Dimension Standard | MSS SP–81 |

| Flange Connection Standards | GB/T9113–2010, EN1092–2002, ASME B16.5–2013, ASME B16.47–2011, AS2129–2000, AS4087–2004, JIS B2220–2004 |

| Inspection & Testing Standard | MSS SP–81 (no visible leakage, special leakage tests available upon request) |

| Body Materials | WCB, CF8, CF3, CF8M, CF3M, 4A, 5A, 904L |

| Temperature-Pressure Rating Standards | GB/T12224–2007, ASME B16.34–2009, ISO7005–1 |

| Typical Applications | Pulp & Paper, Mining, Chemical Industries |

| Actuation Options | Manual, Pneumatic, Electric, Gear, Chain Drive |

Square Knife Gate Valve Main Components and Materials

| Part | Materials | ||

|---|---|---|---|

| Body | WCB | CF8 | CF8M |

| Disc | 304 | 304 | 316 |

| Seat | Hard Seal or EPDM | ||

| O-ring | NBR | ||

| Seat Cover | WCB | CF8 | CF8M |

| Stem Connector | 2Cr13 | 304 | 316 |

| Stem | 2Cr13 | 304 | 316 |

| Bonnet | WCB | CF8 | CF8M |

| Packing | PTFE | ||

| Gland Flange | WCB | CF8 | CF8M |

| Bracket | WCB | CF8 | CF8M |

| Stem Nut | Brass | Brass | Brass |

| Pin | 65Mn | 65Mn | 65Mn |

| Bearing Bush | #45 | #45 | #45 |

| Handwheel | GGG30 (Epoxy Coated) | ||

| Stem Guard | 304 | 304 | 304 |

Square Knife Gate Valve Dimensions

Standardized to MSS SP-81. We also provide drawings upon request.

| Size | A | B | C | D | E | F | G | H | H1 | Cylinder Size | Air Inlet Size | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | |||||||||||

| 100 | 4″ | 51 | 220 | 106 | 150 | 192 | 300 | 120 | 605 | 925 | C125/110 | F1/4 |

| 125 | 5″ | 57 | 195 | 120 | 170 | 215 | 330 | 150 | 620 | 940 | C160/135 | F3/8 |

| 150 | 6″ | 57 | 225 | 130 | 175 | 245 | 350 | 150 | 775 | 1220 | C160/160 | F3/8 |

| 200 | 8″ | 70 | 280 | 130 | 215 | 302 | 440 | 195 | 950 | 1510 | C200/210 | F3/8 |

| 250 | 10″ | 70 | 356 | 140 | 270 | 355 | 505 | 240 | 1165 | 1875 | C250/260 | F3/8 |

| 300 | 12″ | 76 | 405 | 160 | 310 | 401 | 550 | 280 | 1285 | 2110 | C300/310 | F3/8 |

| 350 | 14″ | 76 | 480 | 180 | 330 | 465 | 620 | 380 | 1385 | 2330 | C300/360 | F3/8 |

| 400 | 16″ | 89 | 530 | 180 | 375 | 511 | 670 | 395 | 1530 | 2600 | C320/410 | F3/8 |

| 450 | 18″ | 89 | 610 | 240 | 420 | 580 | 710 | 395 | 1780 | 2965 | C320/460 | F3/8 |

| 500 | 20″ | 114 | 650 | 270 | 465 | 640 | 800 | 425 | 1915 | 3265 | C350/510 | F3/8 |

| 600 | 24″ | 114 | 805 | 270 | 500 | 740 | 910 | 425 | 2190 | 3860 | C350/610 | F3/8 |

Need a special knife gate valve outlet size or flange configuration? Contact us today, TOT Valve can provide you with a fully customized service.

Applications That Demand High Reliability

You can confidently use this square knife gate valve in challenging environments, including:

- Pulp & Paper Mills – Fiber-rich slurry discharge

- Mining & Metallurgy – Thick tailings, abrasive concentrate

- Cement & Bulk Solids – Powder, fly ash, clinker control

- Wastewater Treatment – Sludge and grit isolation

- Chemical Plants – Viscous, corrosive fluid shutoff

- Power Plants – Bottom ash, coal slurry systems

FAQ

What makes this different from a standard knife gate valve?

The square port design eliminates discharge restrictions, making it far superior in bulk material handling or gravity discharge applications.

Can customize the port size or flange type?

Absolutely. You can specify square port dimensions, flange drilling standards (ANSI/DIN/JIS/GB), and even seat/gate material.

Is square port knife gate valve unidirectional or bidirectional?

It is unidirectional. For bidirectional sealing, please inquire about our double-sealing models.

Do TOT Valve offer zero-leakage sealing?

Yes. We provide optional soft seats or advanced sealing systems for zero-leakage requirements.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.