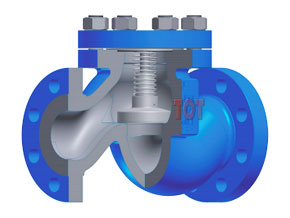

Stainless Steel Lift Check Valve

Spring-Loaded, Flanged Type, Reliable Backflow Protection, Even in Horizontal Pipelines

When you install a check valve, you want one that closes precisely and consistently—regardless of flow conditions or installation direction. Our stainless steel lift check valve uses a built-in stainless steel spring to control the valve disc movement. This ensures the disc opens smoothly under forward pressure and closes instantly when the flow stops or reverses.

Unlike gravity-only designs, the spring-loaded mechanism offers stable, silent, and faster shut-off, especially in horizontal pipelines, where traditional lift check valves may fail to close properly.

Contact us now to get the best ex-factory lift check valve prices.

Description

This is a non-return valve with a vertically moving disc guided inside a stainless steel body. As fluid flows forward, the disc is lifted by pressure; when the pressure drops, the built-in highly resistant to corrosion spring pushes the disc back onto the seat—effectively blocking any reverse flow.

The entire wetted area, including disc, spring, seat, and body, is made from 304 or 316 stainless steel, making the valve highly resistant to corrosion, even in aggressive or hygienic applications. With flanged connections, it integrates easily into your existing pipeline without welding or threading.

Get a quote now and let us help you find the right lift check valve for your application in the shortest possible time.

Stainless Steel Lift Check Valve Features

- Spring-Loaded Disc (Stainless Steel): Ensures fast, vibration-free closure in any installation direction.

- Solid Stainless Steel Body & Trim: Available in SS304 or SS316 for excellent corrosion resistance and durability.

- Precision-Ground Metal or Soft Seat: Leak-tight sealing with PTFE or NBR available for special media compatibility.

- Flanged Connections (PN16 / ANSI 150): Easy to bolt on or replace—standard sizes from DN15 to DN200.

- Low Cracking Pressure: Opens with minimal upstream force, ideal for low-pressure systems.

- Maintenance-Free Design: No manual parts, no external actuators, and no frequent servicing needed.

- Compact Face-to-Face Dimensions: Saves space in tight piping systems.

Stainless Steel Lift Check Valve Implementation Standards

| Design Criteria | Structure Length | Connecting Flange | Test & Inspection |

| BS1868 | ASMEB16.10 | ASMEB16.5 | API 598 |

Stainless Steel Lift Check Valve Materials of Construction

| Part | Material | |

| Body | CF8 | WCB |

| Disc | CF8 | 2Cr13 |

| Shim | PTFE | 304+GRAPHITE |

| Seat | CF8 | 2Cr13 |

| CAP | CF8 | WCB |

*All materials are tested for corrosion resistance and pressure performance under ISO standards.

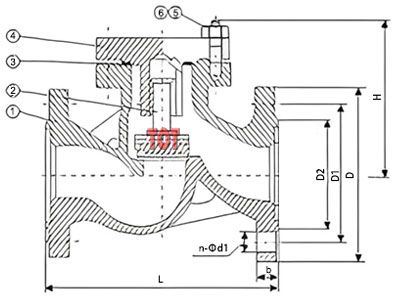

Stainless Steel Lift Check Valve Dimensions

| DN | INCH | L | D | D2 | D1 | b | n-φd1 | H |

| 15 | 1/2″ | 130 | 15 | 45 | 65 | 14 | 4-14 | 65 |

| 20 | 3/4″ | 150 | 20 | 55 | 75 | 14 | 4-14 | 68 |

| 25 | 1″ | 160 | 25 | 65 | 85 | 14 | 4-14 | 73 |

| 32 | 1-1/4″ | 180 | 32 | 78 | 100 | 16 | 4-18 | 78 |

| 40 | 1-1/2″ | 200 | 40 | 85 | 110 | 16 | 4-18 | 85 |

| 50 | 2″ | 230 | 50 | 100 | 125 | 16 | 4-18 | 103 |

| 65 | 2-1/2″ | 290 | 65 | 120 | 145 | 18 | 4-18 | 117 |

| 80 | 3″ | 310 | 80 | 135 | 160 | 20 | 4-18 | 132 |

| 100 | 4″ | 350 | 100 | 155 | 180 | 20 | 4-18 | 147 |

| 125 | 5″ | 400 | 125 | 185 | 210 | 22 | 4-18 | 162 |

| 150 | 6″ | 480 | 150 | 210 | 240 | 22 | 8-22 | 188 |

| 200 | 8″ | 600 | 200 | 295 | 295 | 24 | 12-22 | 222 |

*Custom drilling and other flange standards available upon request.

Applications

This stainless steel lift check valve is best suited for:

- Chemical process lines – Resists corrosion from mildly aggressive media

- Steam and boiler feed – Reliable shutoff during pressure drop

- Food and beverage – Stainless material meets hygiene standards

- Water and wastewater – Works in treated water and backflow zones

- Marine and offshore – No rust, even in salt-heavy environments

- Compressed air and gas – Silent sealing without bounce-back

Let’s Get You the Right Lift Check Valve. Tell us your medium, temperature, and pipe specs—we’ll recommend the ideal configuration. We also offer datasheets, 3D models, pressure test certificates, and customization options.

FAQ

What is a stainless steel lift check valve?

A lift check valve allows fluid to flow in one direction and prevents backflow. In this design, a disc lifts vertically when fluid moves forward, and closes when the flow reverses. Stainless steel versions are corrosion-resistant and ideal for demanding environments.

What is the function of the spring inside the valve?

The built-in spring assists in rapid closure of the disc when flow stops or reverses. This ensures tight shutoff, reduces water hammer, and makes the valve suitable for installations where gravity alone isn’t enough—like vertical pipelines.

What are the main benefits of using a stainless steel lift check valve?

- Excellent resistance to corrosion and scaling

- Fast and quiet closing thanks to spring-loaded design

- Reliable in both vertical and horizontal flow positions

- Minimal pressure drop and low cracking pressure

- Long service life with minimal maintenance

How do choose the right lift check valve?

Consider the following factors when selecting:

- Pipe size and flange standards (DIN/ANSI/JIS)

- Working pressure and temperature range

- Fluid type and corrosiveness

- Installation direction and available space

- Need for soft seat sealing (PTFE/NBR)

Is regular maintenance required?

Not frequently. This valve is designed for maintenance-free operation. However, in systems with dirty fluids or solids, occasional inspection of the disc and seat is recommended to ensure tight sealing and reliable operation.

Is this valve suitable for food, beverage, or pharmaceutical applications?

Yes. When made with 316 stainless steel and PTFE soft seats, this valve meets hygienic standards and can be used in clean process systems, including those in food, dairy, and pharmaceutical plants.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.