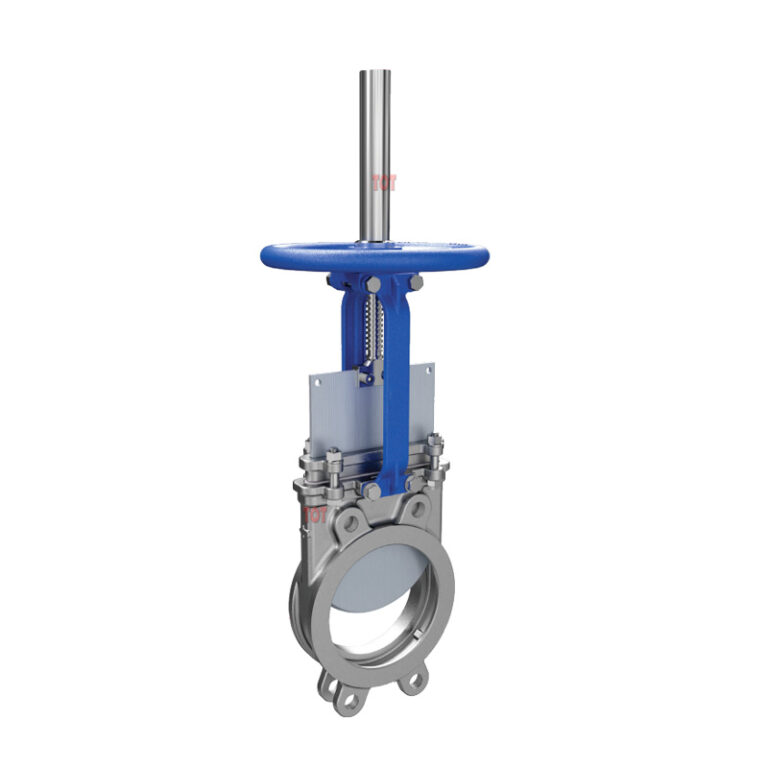

V-Port Knife Gate Valve

Your All-in-One Flow Control Solution for Slurries, Fibers, and Tough Process Fluids

If you’re dealing with flow systems that involve thick slurry, pulp, or semi-solid fluids, you know that standard isolation valves just don’t cut it—literally. That’s where the V-port knife gate valve, also known as a V-notch knife gate valve, makes all the difference.

And if your system deals with variable flow, solids build-up, or harsh chemicals, you can count on this flow control knife gate valve to perform reliably with minimal maintenance.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

The V Port Knife Gate Valve is a type of modulating knife gate valve designed with a V-cut in the gate. This allows you to regulate flow with far greater precision than conventional on/off knife gates. Unlike a simple shut-off valve, this one handles partial open conditions with stability, repeatability, and control.

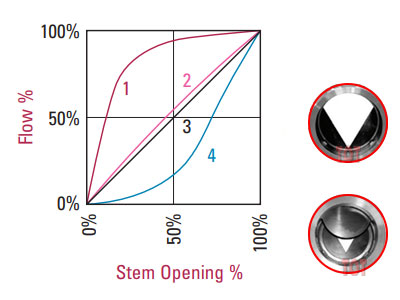

You’ll benefit from a valve that not only cuts through solids, but also enables linear or equal-percentage flow profiles, turning your isolation valve into a throttling knife gate valve that delivers true process control.

TOT Valve By integrating precise throttling capabilities into a rugged knife gate design, this valve gives you both accurate flow modulation and tight shut-off in one compact body. Whether you’re in pulp & paper, wastewater, mining, or chemical processing, this is the control knife gate valve you’ve been looking for.

Get a quote now and let us help you find the right V-port knife gate valve for your application in the shortest possible time.

V Port Knife Gate Valve Features

- Multiple Angles Options – TOT Valve Available with V cuts at 30°, 60°, and 90° for application-specific control curves

- V-Notch Gate Design – Provides consistent and accurate throttling control

- Thick Media Ready – notched knife gate valve design cuts through pulp, slurry, and solids with ease

- Precision Flow Control – Acts as both a segmented knife gate valve and modulating valve

- Low Maintenance Construction – Minimal moving parts reduce service downtime

- Flush Port Integration – Prevents clogging in high-solid-content flows

- Compact Wafer/Lug Style – Fits into tight spaces and retrofit projects

- Adaptable Actuation Options – Pneumatic, electric, hydraulic, or manual

Main Technical Parameters & Performance

| Specification | Details |

| Valve Type | V-Notch / V Port Knife Gate Valve |

| Size Range | DN50–DN600 (2″–24″) |

| Pressure Rating | Up to PN 10/16/ANSI 150/JIS 10K |

| Seal Tightness | MSS SP-81 |

| Face to Face | MSS SP-81 |

| Temperature | -20°C to 180°C (based on seat material) |

| Flow Profile | Linear or Equal Percentage |

| Operation Mode | Manual, Pneumatic, Electric, Hydraulic |

| End Connections | Wafer, Lug, Flanged (ANSI, DIN, JIS) |

| Appliction | Slurries, Fibers, Pulp & Paper, Water Treatment, Beverage & Food, Fine Chemical, Power Plant, Steel Industry, etc. |

Main Components and Materials

| Component | Material Options |

| Body | WCB, CF8, CF8M, CF3M, Duplex SS |

| Gate | SS304, SS316, Hardened Steel, Stellite Coated |

| Seat | EPDM, Nitrile, PTFE, Viton, Metal |

| Stem | SS304 / SS316 |

| Packing | PTFE with EPDM / Graphite |

| Yoke & Hardware | Carbon Steel / Stainless Steel |

| Actuator Housing | Coated Carbon Steel or Aluminum |

Applications That Require High Reliability

You need a valve you can trust—especially in demanding environments. Here’s where the V Port Knife Gate Valve truly shines:

- Pulp & Paper Industry: Control the flow of pulp slurry, recycled fibers, and white water with precision

- Mining and Mineral Processing: Throttle abrasive tailings, ore slurry, and thickened waste with minimal wear

- Wastewater Treatment Plants: Handle sludge and digestate with reliable shut-off and smooth modulation

- Chemical and Petrochemical Plants: Tolerate corrosive and viscous media in tight, automated process lines

- Power Generation: Regulate cooling water, fly ash slurry, and blowdown flows under tough conditions

- Bulk Material Handling: Control dry solids, powders, or granules in gravity or pneumatic conveyors

Need a knife gate valve that works on your terms? You shouldn’t have to choose between isolation and control. TOT With a V-port knife gate valve, you get both—engineered for high performance and built to your specs. If you’re upgrading from a standard gate valve or searching for a more reliable modulating knife gate valve, our are ready to assist.

Request a quote, ask for a technical datasheet, or talk directly with our valve specialists today.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.