Wafer Type Swing Check Valve

This wafer swing check valve provided by TOT Valve is a long pattern single plate check valve, also known as a wafer swing check valve, which has the same performance as other swing check valve but the cost is much lower. Our long pattern single plate check valves are commonly made of high-quality stainless steel (CF8/CF8M) or WCB and other materials.

When reverse flow is not an option, and space is limited, you need a valve you can trust. Our Wafer Type Swing Check Valve offers you a low-maintenance, compact solution that ensures unidirectional flow and prevents water hammer—perfect for critical systems across multiple industries.

Whether you need 1 piece or more, we can deliver tested, performance-qualified products on time.

Description

Designed for flange-to-flange installation, this wafer-style swing check valve uses a hinge disc that swings open under forward flow and closes smoothly when flow stops or reverses.

It’s ideal for liquid or gas systems where quiet, automatic operation and minimal pressure loss are essential. The short face-to-face dimension allows easy installation even in tight spaces, while the simple structure ensures long service life with minimal maintenance.

Get a quote now and let us help you find the right single plate check valve for your application in the shortest possible time.

Wafer Type Swing Check Valve Features

- Thin wafer-type body design for compact installation

- Low cracking pressure, ensuring quick response to flow direction changes

- Hinge swing disc design with high flow capacity and low pressure drop

- Non-slam operation to reduce water hammer and protect pipelines

- Suitable for both horizontal and vertical (upward flow) mounting

- Available in wide range of sizes and materials, available in corrosion-resistant materials like stainless steel

- Compatible with EN, ANSI, DIN, and JIS flanges

- API 598 / EN 12266 pressure tested for guaranteed performance

- No external power or actuator needed—fully automatic

Main Technical Parameters & Performance

| Parameter | Specification |

| Size Range | DN50–DN600 (2″–24″) |

| Working Pressure | PN10 / PN16 / Class 150 |

| Test Standard | API 598 / EN 12266 |

| Working Temperature | -10°C to +180°C (depending on material) |

| Media | Water, air, oil, gas, weak acids/alkalis |

| Flow Direction | One-way (arrow marked on valve body) |

| Connection Type | Wafer type, fits standard flanges |

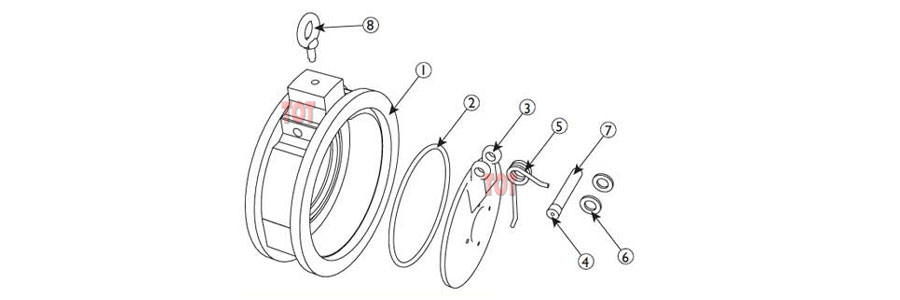

Main Components and Materials

| Part | Materials |

|---|---|

| Body | Stainless Steel A351 Gr, CF8, CF8M, WCB |

| Seat | Viton, PTFE Commercial O-RING |

| Disc | Stainless Steel AISI 316/304 |

| Plug | Stainless Steel AISI 316/304 |

| Spring | Stainless Steel AISI 304/316 |

| Spacer | PTFE Commercial |

| Shaft | Stainless Steel AISI 316/304 |

| Eye Bolt | Carbon Steel ASTM A307B |

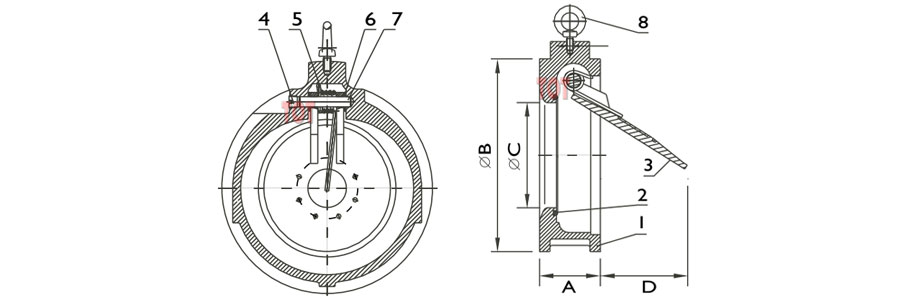

Valve Dimensions

TOT valve can provide you with various sizes of single plate check valve. We have listed some water type single plate check valve for DN50-DN300 for your reference.

If you don’t have the single plate wafer type check valve you need, you can contact us immediately. Our professional sales manager will contact you and can provide you with exclusive ODM and OEM services.

| Size | A(mm) | ØB(mm) | ØC(mm) | D(mm) | Assembled(LB) | Flow Coefficient(Cv) | |

|---|---|---|---|---|---|---|---|

| DN(mm) | NPS(inch) | ||||||

| 50 | 2″ | 45 | 105 | 34 | 13 | 5.0 | 62 |

| 65 | 2-1/2″ | 48 | 124 | 47 | 20 | 6.0 | 109 |

| 80 | 3″ | 51 | 137 | 53 | 34 | 8.0 | 166 |

| 100 | 4″ | 58 | 175 | 77 | 59 | 12.0 | 318 |

| 125 | 5″ | 64 | 197 | 96 | 70 | 18.0 | 471 |

| 150 | 6″ | 70 | 223 | 121 | 86 | 22.0 | 720 |

| 200 | 8″ | 74 | 280 | 164 | 102 | 15.9 | 1384 |

| 250 | 10″ | 80 | 340 | 194 | 121 | 25.8 | 2298 |

| 300 | 12″ | 86 | 410 | 242 | 127 | 38.5 | 4153 |

Applications That Require High Reliability

Rely on our wafer swing check valve in environments where durability and smooth flow control are critical:

- Potable water distribution systems

- Power plant cooling water loops

- Industrial process lines and recirculation systems

- Chemical dosing and drainage lines

- Desalination and marine piping

- Crude oil and gas transmission lines

- Firefighting and sprinkler systems

FAQ

What is a wafer type swing check valve?

A wafer type swing check valve is a compact, one-way valve designed to prevent backflow in piping systems. It features a swinging disc that opens with forward flow and closes when the flow reverses, ensuring unidirectional flow. Its wafer-thin design allows for installation between two flanges, making it ideal for systems with limited space.

How does a wafer swing check valve differ from a traditional swing check valve?

While both valves use a swinging disc mechanism, the primary difference lies in their body design. Wafer swing check valves have a slim profile suitable for tight spaces, whereas traditional swing check valves have a bulkier body that requires more installation space. Additionally, wafer check valves may have a slightly higher flow resistance due to their compact design.

In which applications are wafer swing check valves commonly used?

Wafer swing check valves are versatile and used in various industries, including:

- Water treatment and distribution systems

- HVAC systems

- Chemical processing

- Power plants

- Mining operations

- Swimming pools and aquariums

Their compact design makes them especially suitable for systems where space is a constraint.

Can wafer swing check valves be installed vertically?

Yes, wafer swing check valves can be installed in both horizontal and vertical orientations. However, for vertical installations, it’s essential to ensure that the flow direction is upward to allow the disc to open properly.

How do I select the appropriate wafer swing check valve for my system?

When selecting a wafer swing check valve, consider the following factors:

- Size and pressure rating: Ensure the valve matches the pipeline’s diameter and operating pressure.

- Material compatibility: Choose materials that are compatible with the media (e.g., water, chemicals) and operating conditions.

- Installation orientation: Confirm whether the valve will be installed horizontally or vertically.

- Flow characteristics: Assess the flow rate and velocity to ensure the valve operates efficiently.

Consulting with a valve specialist or referring to manufacturer specifications can aid in making the appropriate selection.

What are common issues associated with wafer swing check valves?

Some potential issues include:

- Water hammer: Sudden closure can cause pressure surges.

- Wear and tear: Continuous operation can lead to disc or hinge wear.

- Improper installation: Incorrect orientation can affect valve performance.

Regular maintenance and proper installation can mitigate these issues. If you have further questions or need assistance in selecting the right valve for your application, feel free to contact our technical support team.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.