Industrial Valve Manufacturer in China

TOT Valve produces a wide range of gate valves, knife gate valves, butterfly valve, ball valve and check valve works that are used in various industrial segments such as Water Treatment, Mining, Power Generation, Pulp and Paper, Food and Beverage, Petrochemical Industry, Steel Industry, Air Separation and Dams, Reservoirs and Hydro Solutions.

Be careful when choosing a new valve supplier, the disappointment of poor quality can last much longer than the joy of a low price!

Unmatched Durability

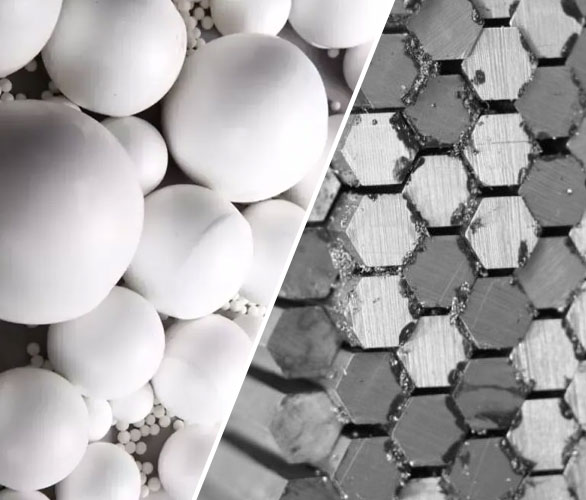

High-Grade Materials: TOT Valve is made of the highest quality 304/316 stainless steel and ceramics, and is carefully crafted to ensure the valve’s long life and wear resistance.

Precision Engineering: Each valve components is meticulously designed to meet exact specifications, give you a perfect fit every time.

Corrosion Resistance: The nickel content of our valves meets international standards (≥8%). It is well known that the higher the nickel content of stainless steel, the stronger the acid and alkali resistance of the stainless steel valve.

Quality Assurance: TOT Valve Rigorous testing processes guarantee that every product meets the highest standards of performance and safety.

Excellent Performance

Optimal Flow Rate: TOT Valve design ensures maximum fluid flow while minimizing pressure, thereby improving the efficiency of your system.

Leak-proof Design: Our leading sealing technology prevents leaks in your system and ensures reliable and stable performance under high pressure.

Versatility: It is never picky about your use environment and is an ideal choice for applications such as water treatment, mining, power generation, pulp and paper, food and beverage, petrochemical industry, steel industry, etc.

Easy Installation: TOT Valve is designed for quick and direct installation, reducing your system downtime and maintenance costs.

TOT Valve Manufacturing and Quality Control

At TOT Valve, our manufacturing process is carefully designed to ensure the production of the highest quality industrial valves.

Material Preparation: We use high-grade raw materials such as high-quality SS 304/SS 316L/SS316Ti stainless steel, brass and ceramics.

Valve Body Processing: We have our own foundry, where we cast the raw materials precisely.

Valve assembly: Assemble the valve body, valve stem, valve seat, seals and other parts. We generally use a combination of mechanical processing and manual assembly.

Valve Testing: TOT Valve has a strict quality inspection system and tests the assembled valves, including size, leak plugging, corrosion resistance, pressure resistance and other tests.

Cleaning and Surface treatment: Clean the assembled valves to remove surface impurities and stains, or perform surface treatments such as polishing, sandblasting, and spraying.

Packaging and Storage: Pack the valves, mark and record them, and store them in the designated warehouse.

By adhering to these meticulous manufacturing processes, TOT ensures that every industrial valve produced meets the highest standards of quality and performance. Our commitment to excellence in every step of production reflects our dedication to providing quality products that our customers can trust.