In fluid handling systems, flow direction matters more than you might think. A sudden reversal of flow (also known as backflow) can damage equipment, disrupt processes, or even cause safety hazards. That’s where check valves come into play.

In this article, we’ll walk you through what check valves are, how they work, and why they are essential across industries like water treatment, oil & gas, chemical processing, and HVAC. Whether you’re designing a new system or troubleshooting an existing one, understanding check valves can save you time, cost, and maintenance headaches.

PS: TOT valve is committed to providing excellent products and services to help you build high-quality solutions for fluid control systems. You are welcome to consult our product catalog for more product information through enquiry@okvalveservice.com. You can also visit our okvalveservice.com site to get more resources about high-quality valves and their applications.

Table of Contents

ToggleWhat Is a Check Valve?

A check valve, sometimes called a non-return valve or one-way valve, is a mechanical control device that allows liquid or gas fluid to flow in only one direction. It automatically prevents reverse flow without the need for manual operation or external control.

Check valves operate based on pressure differential. When the pressure on the inlet side exceeds a certain threshold (known as cracking pressure), the valve opens. If the flow stops or attempts to reverse, the valve closes—sealing the line and preventing backflow.

How Does a Check Valve Work?

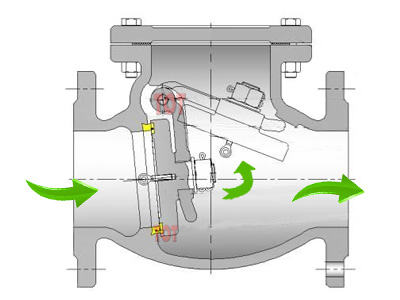

It opens when fluid pressure flows in the expected direction; it closes when reverse flow occurs. Understanding the working principle of the check valve can help you ensure better system reliability, safety and maintenance planning.

- Forward Flow Begins: The pressure from the upstream side pushes the internal disc, ball, or flap open.

- Flow Continues: As long as the upstream pressure remains higher than the downstream pressure, fluid flows freely.

- Reverse Flow Attempts: When pressure drops or reverses, gravity or spring force pushes the internal mechanism back onto the valve seat, closing the valve and stopping the flow.

Because check valves function automatically, they are ideal for systems that require passive protection against reverse flow.

Types of Check Valves

At TOT Valve, Each type is built to suit specific flow conditions, pressure ratings, and installation orientations. From swing and lift valves to diaphragm and spring-loaded designs, you’ll find that the right choice depends on how you want your system to perform under varying conditions. Understanding the different types of check valves available can help you make a smarter, more efficient decision.

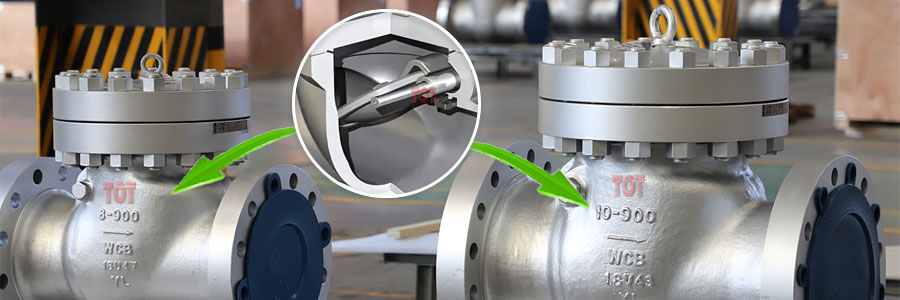

Swing Check Valve: It uses a hinged disc that swings open when flowing forward and closes when flowing backward. It is an ideal choice for horizontal pipes with medium and low flow rates. It has a simple design and is commonly used in water supply, sewage treatment and HVAC systems.

Lift Check Valve: Allow fluid to flow by lifting a disc vertically off the seat. When flow stops, the disc drops back to block reverse flow. These valves work well in high-pressure systems and are often found in steam, gas, and boiler applications.

Ball Check Valve: Use a spherical ball to control flow direction. The ball moves off the seat when flow starts and reseats to stop backflow. They’re excellent for slurry, viscous, or dirty fluids, especially in wastewater and chemical systems.

Dual Plate Check Valve: Also known as double disc check valve or butterfly check valve, feature two spring-loaded plates that open with flow and close rapidly when flow stops. Their compact wafer design makes them ideal for space-constrained systems like HVAC, refineries, and marine applications.

Single Plate Check Valve: It is a wafer-type check valve. This valve is ultra-compact and installed between flanges. It uses a swing or single-piece mechanism. They are lightweight and easy to install. They are often used in compact pipe layouts and general industrial applications with limited space.

Foot Valve: Is a check valve installed at the bottom of a pump suction line, usually with a strainer. It prevents backflow and keeps the pump primed. Commonly used in wells, tanks, and irrigation systems to improve pump efficiency and reliability.

What Is the Function of a Check Valve?

A check valve plays a critical role in any fluid control system by allowing flow in only one direction and preventing reverse flow. It operates automatically without manual operation or external control making it an essential safety and efficiency component in piping networks. Here are the main check valve functions:

Prevent Backflow: The primary function of a check valve is to stop reverse flow when the upstream pressure drops or flow direction changes. This protects equipment and processes from contamination or disruption.

Protect Equipment: In pump and compressor systems, check valves prevent backflow that can cause impeller reverse rotation, water hammer, or sudden pressure surges—helping avoid costly damage and downtime.

Maintain System Pressure: Check valves help retain pressure in critical parts of the system. This is especially useful in multi-stage pumping systems or systems with pressure-sensitive zones.

Avoid Media Contamination: In pipelines carrying different process fluids, check valves prevent the unwanted mixing of media, safeguarding product purity and process integrity.

Enable Automatic Operation: Check valves require no actuation or operator input. They open and close based solely on pressure differential, making them ideal for unattended or remote applications.

Where are Check Valves Used?

Check valves are used in almost all industries involving fluid transportation. So where to install check valve? TOT Valve lists some common installation application scenarios:

- Water and wastewater treatment – preventing backflow into clean water lines

- Pumping systems – protecting pumps from reverse rotation and water hammer

- Boiler and steam systems – keeping condensate from flowing backward

- Oil & gas pipelines – isolating sections and preventing product contamination

- HVAC systems – regulating refrigerant or chilled water flow

From small-scale residential setups to large industrial facilities, check valves are key to operational reliability.

Key Factors to Reflect When Selecting a Check Valve

Not all check valves are born the same. Selecting the wrong type or improper installation may result in increased pressure drop, premature wear or damage, noise or vibration, water hammer and other performance issues.

So how to choose the right check valve? TOT Valve recommends that you consider the following factors:

Flow Direction & Orientation: Whether the check valve is installed horizontally, vertically or at an angle. Some check valves like swing check valves only function properly in horizontal lines, while others (e.g., spring-loaded or ball check valves) support vertical installation.

Operating Pressure & Temperature: Always consider the system’s pressure and temperature range. Make sure the check valve’s pressure class and material construction can withstand the operating conditions without failure or deformation.

Media Type (Fluid Characteristics): The nature of the media—clean or dirty, corrosive or non-corrosive, liquid or gas—directly affects valve type and material choice. For example:

Slurries or viscous fluids → Ball check valve

Steam or gas → Lift check valve

Corrosive chemicals → Stainless steel or lined check valves

Closing Speed & Water Hammer Prevention: In fast-closing systems, choose a valve type that minimizes water hammer risk, such as a dual-plate check valve or spring-loaded design. Water hammer can damage pipelines and downstream equipment.

Pressure Drop Requirements: Some check valves, like lift and ball types, create more flow resistance than swing or dual-plate valves. For energy-efficient systems, consider low-pressure-drop designs.

Installation Space: Space constraints can influence valve selection. Wafer and dual-plate check valves are ideal for compact or retrofit installations, while swing check valves may require more room due to their wider body and disc movement.

Maintenance Needs: Evaluate whether the valve allows for easy inspection and servicing. Valves with fewer moving parts or top-entry designs can reduce downtime and maintenance costs.

Compliance & Standards: Make sure the valve meets industry or project-specific standards (API, ASME, DIN, ISO, etc.) especially in regulated industries like oil & gas, pharmaceuticals, or water treatment.

Material Compatibility: The material of the valve body, disc, seat, and internal components must be compatible with the fluid and environmental conditions. Improper material selection can lead to corrosion, erosion, swelling, or even valve failure.

PS: At TOT Valve, we only provide you with high-quality stainless steel check valves and ceramic check valves, which are 100% competent in your corrosive and abrasive fluid control systems.

Conclusion

Understanding the different types, functions, and key selection factors will help you choose the right valve to optimize system performance, reduce maintenance costs, and improve safety. Whether you’re managing water, steam, chemicals, or slurries, selecting the appropriate check valve material, design, and size is critical to achieving reliable and efficient operation. By making informed decisions, you ensure your system runs smoothly and sustainably for the long term.

FAQ

When to Use a Check Valve?

A check valve should be used in any piping system where backflow prevention is critical to protecting equipment, maintaining process integrity, or ensuring safety. It allows flow in one direction only and automatically prevents reverse flow. When you are in the following environment, it is recommended that you use a check valve:

- You need to protect pumps and compressors

- You want to avoid backflow contamination

- You operate systems with variable or pulsating flow

- You want to reduce water hammer risks

- You’re installing systems with storage tanks or reservoirs

Can Check Valves Prevent Water Hammer?

Yes, spring check valves (such as spring loaded lift check valves or double plate check valves) are designed to close quickly and reduce the risk of water hammer, this avoids damage to pipes and equipment.

What Materials are Check Valves Made From?

At TOT Valve, we use high-quality stainless steel and cast steel as raw materials for the check valve body and main components, which are cast or forged through a strict and rigorous quality control process to ensure the service life in your fluid control system. The specific material selection depends on the corrosiveness, temperature, pressure and application environment of your fluid.

How Often Should Check Valves be Maintained?

Maintenance frequency varies based on the valve type, operating conditions, and media cleanliness. Regular inspection and cleaning help prevent valve failure and prolong service life.

What are The Basic Steps to Check Valve Installation?

To install a check valve properly:

Identify the flow direction make sure the valve’s arrow matches the pipeline flow.

Prepare the pipe by cleaning it and making sure the end of the pipe is smooth and free of debris.

Position the valve between flanges or threaded ends, aligning it carefully.

Secure the valve using bolts or thread connections, tightening evenly to avoid leaks.

Test the installation by gradually introducing fluid and checking for leaks or unusual noises.

Can a Check Valve be Installed Vertically or Horizontally?

Some check valves, like swing check valves, are designed for horizontal installation only, while others, such as spring-loaded or ball check valves, can be installed vertically or horizontally. Always consult the manufacturer’s guidelines.

Can Install a Check Valve In a High-Pressure System?

Yes, but ensure the valve is rated for the system’s pressure and temperature. Select a valve type and material suitable for high-pressure applications, such as lift check valves or spring-loaded designs.