In fluid control systems, the reliability of a valve can make or break an operation. Whether you’re managing a municipal water system, refining petroleum, or automating a chemical process, you need valves that are fast, durable, and leak-proof. That’s where ball valves come in.

In this article, we provide a comprehensive, overview of ball valves what they are, how they work, where they’re used, and what to consider when choosing one, hope this helps.

PS: TOT valve is committed to providing excellent products and services to help you build high-quality solutions for fluid control systems. You are welcome to advisory our product catalog for more product information through enquiry@okvalveservice.com. You can also visit our okvalveservice.com site to get more resources about high-quality valves and their applications.

Table of Contents

ToggleWhat Is a Ball Valve?

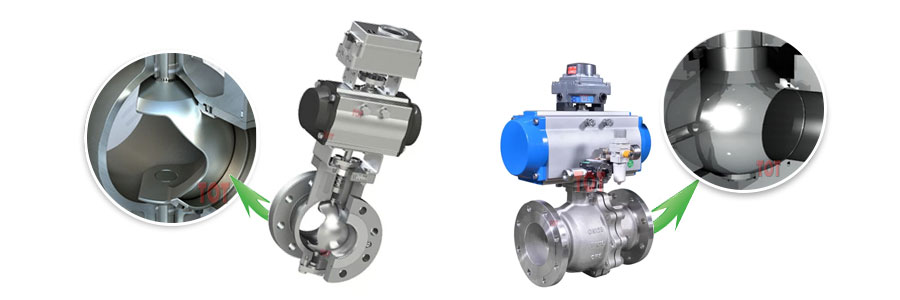

A ball valve is a 1/4 rotary valve that uses a spherical closure element, commonly called a ball, to start or stop the flow of fluid. The ball has a round hole or a V-notch in the center. When the bore is aligned with the pipeline, the media flows freely. A simple 90-degree rotation of the handle or actuator turns the ball, blocking the passage and shutting off the flow.

The design is simple but extremely effective, offering:

- Fast shutoff (¼ turn operation)

- Low torque requirements

- Minimal pressure drop

- Bubble-tight sealing (in soft-seated designs)

In short, ball valves are the preferred solution for controlling on/off flow, especially for systems that require fast and tight closing with low operating force.

How Does a Ball Valve Work?

Ball valves use a hollow, rotating ball to control the flow of liquids or gases. The ball is positioned inside the valve body and contains a hole or V-notch, that allows fluid to pass through when aligned with the pipeline.

Ball Valve Working Principle

Open Position: When the handle or actuator turns the ball 90 degrees, and the bore aligns with the flow path, fluid passes through freely with minimal pressure drop.

Closed Position: Turning the handle another 90 degrees rotates the ball so that the solid side blocks the flow. This completely shuts off the passage and stops fluid movement.

This simple quarter-turn action makes ball valves extremely quick to operate—ideal for on/off control.

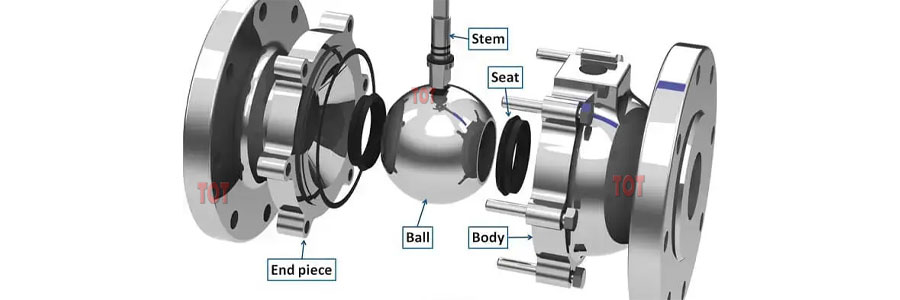

Key Components Involved in Operation

Body: The primary structure of the valve, this robust enclosure contains and protects all internal parts. It’s crafted from durable materials like metal, thermoplastic, or lined metal to withstand the demands of its operating environment. Inlet and outlet ports on the body allow for piping connections.

Ball: The central flow control element, the ball is a sphere with a central hole or V-notch. Rotating the ball determines whether the bore aligns with the flow path or blocks it. Hollow balls have an internal cavity allowing for higher flow rates. So, increased turbulence and higher flow velocities are worth paying attention to.

Stem: The stem connecting the ball to the external control mechanism (usually a handle, but can be automated). Rotating the stem turns the ball, opening or closing the valve. The stem needs robust seals to prevent fluid leaks where it passes through the bonnet.

Seats: Soft rings surround the ball, providing a tight seal when the valve closes. Seats prevent leakage by firmly pressing against the ball.

Bonnet: An extension on the valve body protecting the stem and its seals. The bonnet might be bolted or welded to the body and is essential for high-pressure/temperature operations.

Handle/Actuator: Manual lever, pneumatic, or electric actuator to control rotation.

PS: When you are in a high pressure system, it is recommended that you use a trunnion ball valve. This type of ball valve has fixed supports at both ends to reduce torque and wear on the valve seat. In a low pressure system, a floating ball valve is what we recommend for you, where the ball moves slightly under pressure, presses against the downstream valve seat and ensures sealing.

Types of Ball Valves

Ball valves may look similar on the outside, but inside, they vary significantly in design, flow capacity, and application. Choosing the right type depends on your process requirements—such as flow rate, pressure class, media type, and system layout. Here’s a comprehensive overview of the most common types of ball valves:

Full Port Ball Valve: Also known as full-bore ball valve has an internal bore that matches the pipeline diameter, allowing maximum flow with virtually no restriction or pressure drop. This design is especially important in systems that require high flow efficiency, such as slurry handling, pigging pipelines, or viscous fluid transport where friction loss must be minimized.

Reduced Port Ball Valve: The pipe connected is a reducing pipe to ensure the pressure is moderate. However, they are more compact, cost-effective, and sufficient for many standard applications where flow loss is acceptable. You’ll often find them in HVAC systems, water supply lines, and general industrial shut-off functions.

V-Port Ball Valve: TOT Valve can provide you with 15°, 30°, 45°, 60°, and 90° V-notch balls. This shape allows for a more controlled, linear flow rate, making it ideal for throttling and modulating applications. It’s often used in chemical processing, steam systems, or any operation requiring precise flow control over time.

Floating Ball Valve: It “floats” slightly and uses downstream pressure to push against the seat and form a seal. This simple design is cost-effective and reliable for low- to medium-pressure systems such as water treatment, natural gas, and compressed air networks.

Trunnion-Mounted Ball Valve: In trunnion-mounted designs, the ball is supported by shafts at both ends, which absorb pressure and reduce seat wear. This structure makes them ideal for high-pressure and large-diameter pipelines. They offer lower torque requirements and improved sealing, especially in oil & gas, petrochemical, and underground transmission systems.

Three-Way / Multi-Port Ball Valve: Multi-port ball valves, such as 3-way or 4-way designs, enable fluid diversion, mixing, or flow splitting within a single valve body. They eliminate the need for multiple valves and fittings, simplifying complex piping layouts. Typical applications include sampling systems, CIP loops, tank selection, and bypass systems in process industries.

Top-Entry Ball Valve: Top-entry ball valves allow internal components to be accessed and serviced from the top without removing the valve from the pipeline. This feature reduces downtime and makes them ideal for critical services where inline maintenance is a priority—such as offshore oil rigs, chemical plants, and high-integrity process lines.

Three-Piece Ball Valve: Three-piece ball valves consist of a center body and two end connections, allowing easy removal of the valve body for cleaning, repair, or replacement without disturbing the pipeline. They’re widely used in sanitary, food-grade, and pharmaceutical systems where frequent maintenance and cleaning are required to ensure product integrity.

Cavity-Filled Ball Valve: Cavity-filled ball valves are designed to eliminate the voids around the ball where media can get trapped. This design prevents contamination and residue build-up, making the valve easier to clean and more hygienic. These valves are essential in food, beverage, biotech, and other sanitary applications with strict cleaning protocols.

High-Pressure Ball Valve: High-pressure ball valves are specifically engineered to operate under extreme pressure conditions, often exceeding 6,000 PSI. They typically feature trunnion support, metal seats, and reinforced body structures. These valves are essential in hydraulic power units, chemical injection skids, and high-stress applications in the energy sector.

Material Selection: What Are Ball Valves Made Of?

Choosing the right ball valve material is critical for ensuring compatibility with your media, temperature, pressure, and environmental conditions. At TOT Valve, we only purchase high-quality raw materials such as stainless steel and ceramic. These materials have different performance characteristics and can be selected according to your application environment and fluid media. The following are the most commonly used materials for industrial ball valves and their applications in which components:

| Component | Material Options | Considerations |

|---|---|---|

| Body | Stainless Steel, Carbon Steel, Brass, PVC | Chemical resistance, temperature/pressure ratings |

| Ball | Chrome-plated brass, stainless steel, ceramic | Corrosion, wear, strength |

| Seat | PTFE, RPTFE, Devlon, PEEK, Metal | Soft (tight seal) vs. hard (high-temp/abrasive media) |

| Stem Seals | PTFE, graphite, elastomer | Leakage resistance, temperature |

PS: If you are using corrosive media such as acid or chloride, please choose a stainless steel ball valve. If the fluid medium contains hard particles, it is recommended that you choose a ceramic ball valve.

Why are Ball Valves So Widely Used?

Advantages of Ball Valves

Quick operation (90° turn)

Tight sealing, even after extended cycles

Low maintenance due to simple internal parts

Wide operating range for temperature & pressure

Easy to automate with pneumatic or electric actuators

Versatile across industries and compatible with most pipe systems

Industry Application

Oil & Gas: For high-pressure shut-off and isolation in pipelines, separators, and process skids.

Water & Wastewater Treatment: Used for clean water, sludge, and chemical dosing lines with corrosion-resistant materials.

Chemical Processing: Handles corrosive fluids safely in processing, storage, and transfer lines.

Food & Pharmaceutical: Sanitary-grade valves ensure clean, contamination-free flow in CIP/SIP systems.

Power Generation: Controls steam, condensate, and high-temperature media in power systems.

HVAC & Building Services: Shuts off water and air lines in commercial heating and cooling systems.

Residential & Plumbing: For main water shut-off, gas isolation, and general household plumbing.

How to Choose the Right Ball Valve?

Choosing the right ball valve depends on more than just size and price. You need to consider media type, temperature, pressure, application environment and valve function. Mismatches can lead to leakage, corrosion or system failure. Have you searched for “ball valve selection guide”, which can be roughly divided into the following key factors:

- Media type (liquid, gas, corrosive?)

- Operating pressure and temperature

- Manual or automated operation?

- Decide on End Connections

- Material compatibility

- Certifications (API, ANSI, ISO)

If you still don’t know how to choose the right ball valve for your application system, please contact us and we will make the right decision in the shortest time.

PS: As a professional ball valve manufacturer, we recommend you always consider the total lifecycle cost, not just the price of the ball valve. The right ball valve can last for decades with little or no downtime. But choosing the wrong one, even with low upfront costs, can lead to safety risks, production delays, and expensive maintenance costs.

Conclusion

Choosing the right ball valve isn’t just about size or price—it’s about ensuring long-term reliability, safety, and efficiency in your system. By carefully evaluating your media, pressure, temperature, and connection needs, you can avoid costly failures and downtime. Whether you’re working with water, oil, chemicals, or steam, selecting a valve that matches your application’s demands is essential. If you’re unsure, consulting with a valve specialist can save time and help you make a confident, informed decision.

FAQ

What is difference between gate valve and ball valve?

The primary difference is in how they open and close. A gate valve uses a vertical gate that slowly rises or lowers to control flow, while a ball valve uses a rotating ball with a hole through it for quick quarter-turn shutoff. Ball valves offer faster operation and tighter sealing.

How to choose the material of ball valve according to the application?

When choosing the material of ball valve, the type of fluid, temperature, pressure and environmental conditions should be considered. For example, stainless steel ball valves are suitable for corrosive media, ceramic ball valves are suitable for abrasive media, PVC is suitable for low-pressure water systems, and brass is often used in residential water supply systems.

How to determine the size of ball valve?

The size of ball valve should match the diameter of the pipe, taking into account the required flow rate and pressure drop. Generally, using full-port valves can minimize pressure loss.

Is ball valve suitable for throttling control?

Although ball valves are mainly used for on-off control, some types (such as V-port ball valves) can be used for throttling control. However, for applications requiring precise flow regulation, other types of valves, such as needle valves or regulating valves, may be more appropriate.

How to choose the actuation method of ball valve?

The actuation methods of ball valves include manual, electric and pneumatic. The frequency of operation, automation requirements and site conditions should be considered when selecting. For example, remote control systems may require electric or pneumatic actuation, while simple on-off operations can be manually actuated.

How to ensure the sealing performance of the ball valve?

Choosing the right sealing material (such as PTFE, RTFE or metal seal) is crucial to ensure the sealing performance of the ball valve. In addition, regular maintenance and inspection also help maintain the sealing performance.